Special jig for hoisting of crushing teeth of crushing machine

A special fixture and crushing tooth technology, applied in the directions of transportation and packaging, load hoisting elements, etc., can solve the problems of broken teeth slipping, low safety, difficult hoisting positioning, etc., and achieves improved hoisting work efficiency, simple structure, and hoisting. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The embodiments are not intended to limit the scope of protection of the invention. Obviously, those skilled in the art can obtain other embodiments without having to pay creative work. Belong to the protection scope of the present invention.

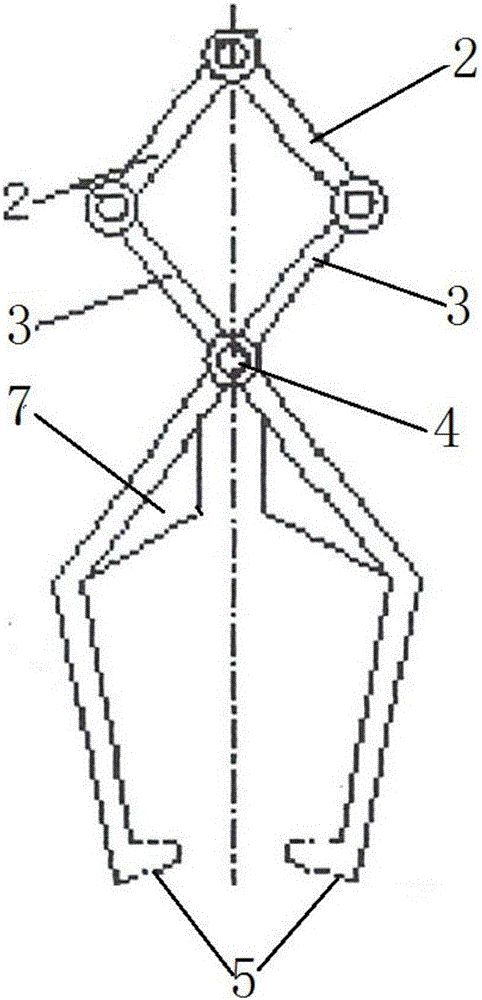

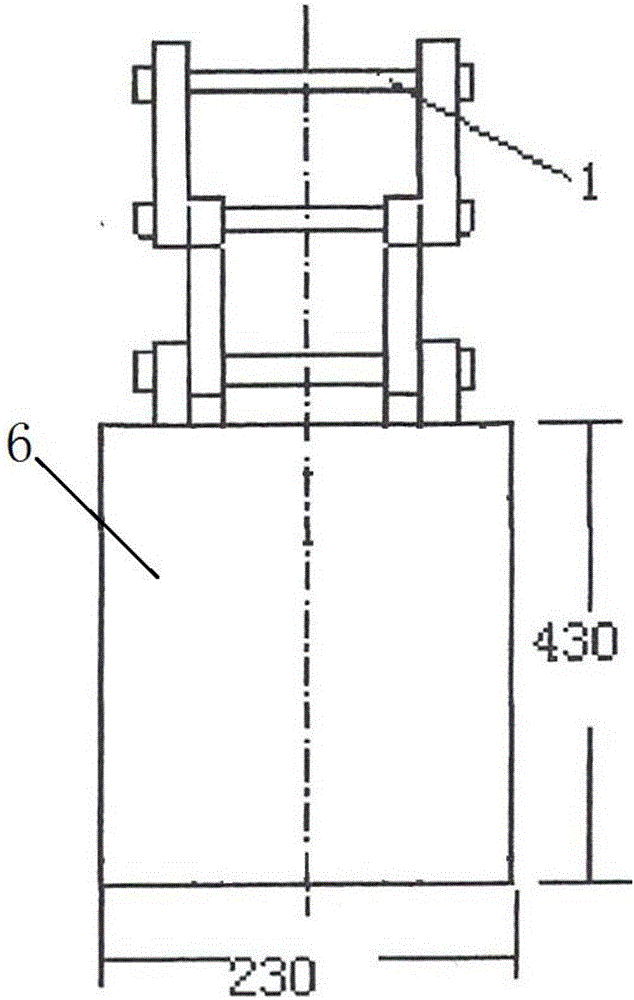

[0019] combine figure 1 and figure 2 As shown, a special fixture for hoisting broken teeth of a crusher, which includes a hoisting frame 1, two connecting rods 2, and two symmetrically arranged hinge rods 3, the top ends of the two connecting rods are hinged on the hoisting frame, and the connecting rods The bottom of the hinge is hinged with the top of the hinge rod, and the two hinge rods are hinged by pin 4, and the bottom ends of the two hinge rods are bent inwardly to form hook pincers 5.

[0020] A further improvement is that a reinforcing plate 6 is fixed on the outside of the two hinge rods.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com