Premixing-free solvent-free compound machine and grouping pre-coating solvent-free compound method

A solvent-free laminating machine and pre-mixing technology, applied in chemical instruments and methods, layered products, lamination devices, etc., to achieve the effect of good effect, high control precision and precise coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

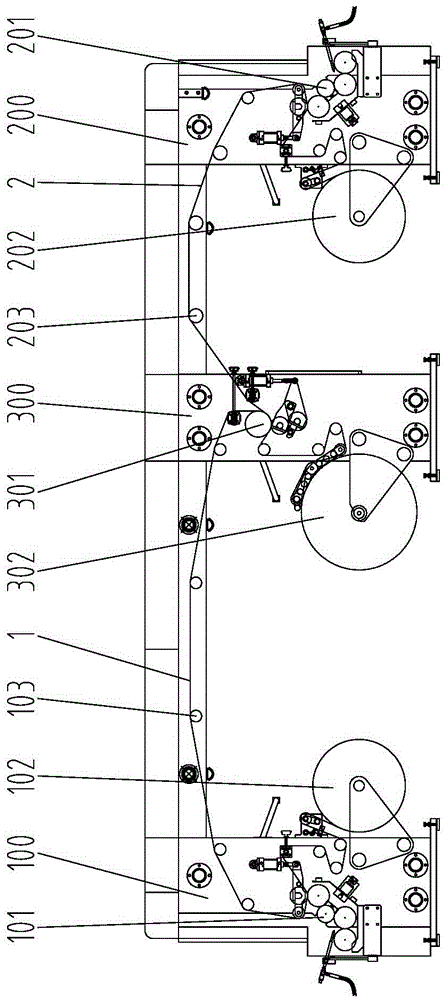

[0030] Such as figure 1 As shown, it is a structural schematic diagram of the first embodiment of the premix-free and solvent-free composite machine of the present invention.

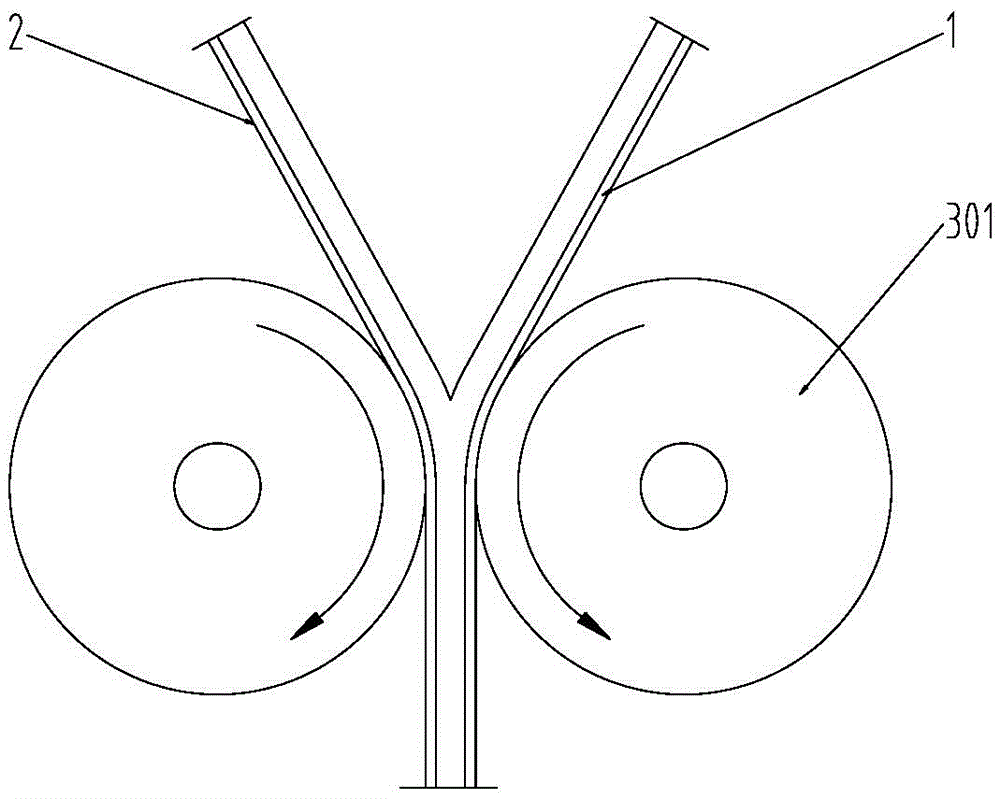

[0031]The non-premixing and solvent-free composite machine of this embodiment includes a first coating device 100, a second coating device 200 and a composite device 300, and the first coating device 100 is provided with a first coating mechanism 101 and a first coating device 100. The coating mechanism 101 corresponds to the first unwinding mechanism 102, the second coating device 200 is provided with the second coating mechanism 201 and the second unwinding mechanism 202 corresponding to the second coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com