A tower inspection robot and its working method

A robot and iron tower technology, applied in the field of robots, can solve the problems of increasing the unsafe operation factor, the tower and the line with diseases, increasing the risk factor, etc., and achieves the effect of reducing the cost of climbing, strong versatility, and improved controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

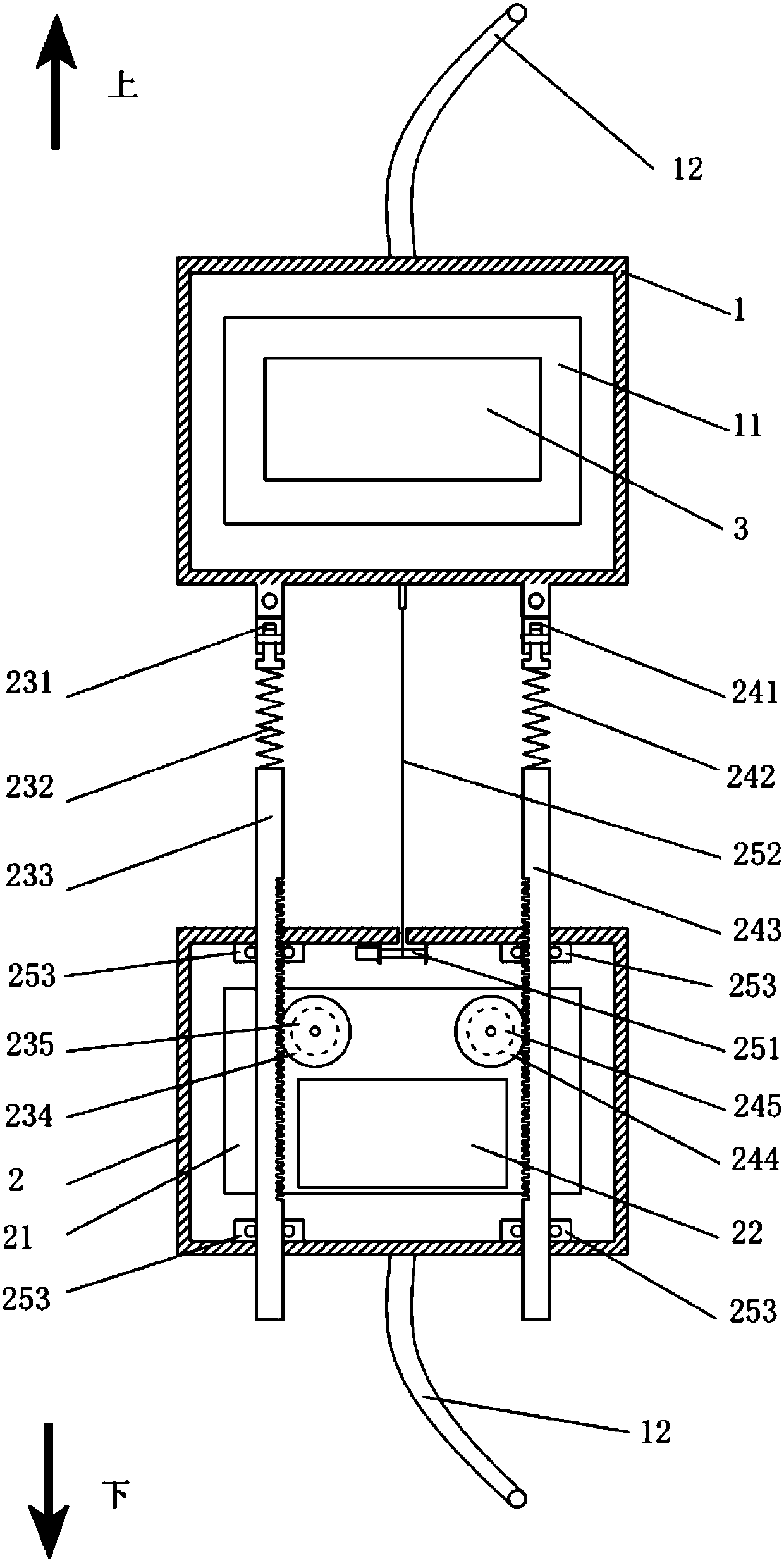

[0050] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0051]In addition, it should be noted that, unless otherwise specified or pointed out, the terms “upper”, “lower”, “left”, “right” and other descriptions that may be involved in the specification are only used to distinguish the various components, elements, Steps, etc., rather than expressing the logical relationship or sequence relationship between components, elements, and steps.

[0052] The related words of "forward work" and "reverse work" of the left drive motor and the right drive motor are only used for convenience of description, and do not represent the specific running direction of the motor.

[0053] like figure 1 And me figure 2 As shown, a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com