Curing method for heavy metals in waste incineration ash and application thereof

A technology of waste incineration ash and solidification method, which is applied in the fields of environmental protection and solid waste resource utilization, can solve problems such as environmental and groundwater pollution, threaten human health, etc., and achieve the effect of no waste gas emission and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

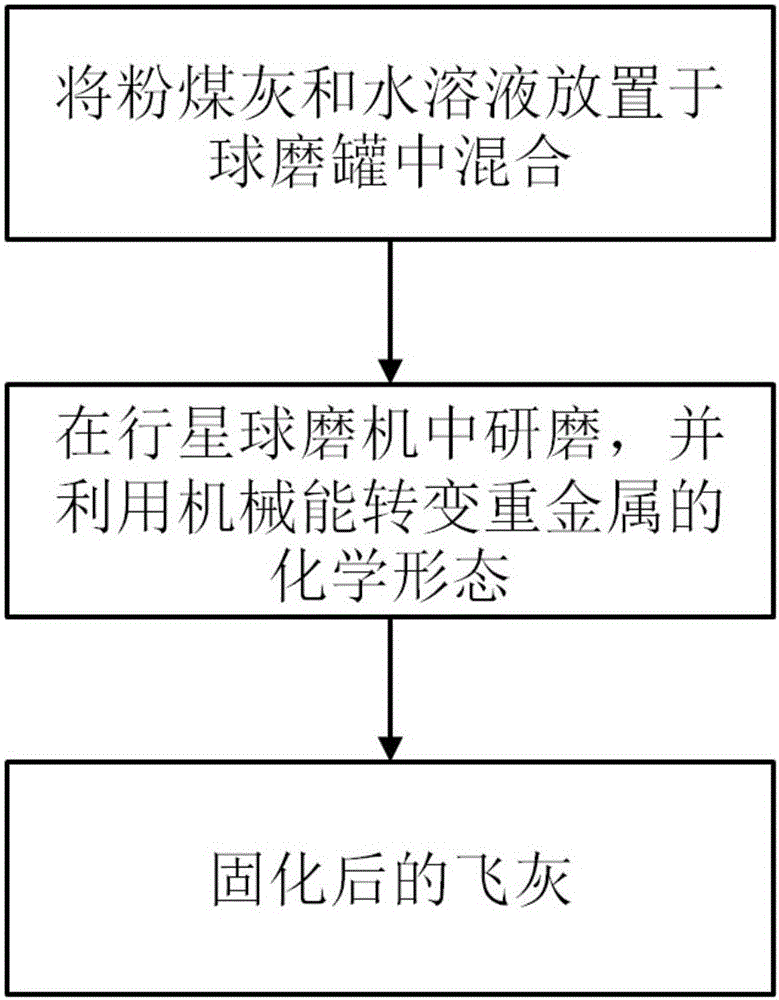

Method used

Image

Examples

Embodiment 1

[0025] This embodiment 1 is solidifying the heavy metals in the fly ash of the waste incineration of the grate furnace, which specifically includes the following steps:

[0026] (1) Get 8g of waste incineration fly ash under the grate furnace incineration mode, dissolve it in 80ml deionized water, mix well, and make a mixed solution;

[0027] (2) Get the grinding balls so that the solid mass ratio of the total mass of the grinding balls to the grate furnace waste incineration ash in step (1) is 12 (that is, the total mass of the grinding balls is 96g). Add the grinding balls to the mixed solution prepared in step (1); the grinding balls with a total mass of 96g can be combined in the following way: 30 small-sized grinding balls with a diameter of 6mm, and 20 large-sized grinding balls with a diameter of 10mm .

[0028] (3) Put the ball mill jar in a planetary ball mill, and work for 24 hours at normal temperature and pressure with a rotating speed of 250 rpm;

[0029] (4) Ta...

Embodiment 2

[0031] This embodiment 2 is to solidify the heavy metals in the fly ash of fluidized bed waste incineration, which specifically includes the following steps:

[0032] (1) Get 8g of waste incineration fly ash under the fluidized bed incineration mode, dissolve in 80ml of deionized water, mix well, and make a mixed solution;

[0033] (2) Take the grinding balls so that the ratio of the total mass of the grinding balls to the solid mass of the waste incineration ash in the step (1) is 12, and add the grinding balls to the mixed solution prepared in the step (1). The grinding balls with the above total mass can be combined in the following manner: 30 small-sized grinding balls with a diameter of 6 mm, and 20 large-sized grinding balls with a diameter of 10 mm.

[0034] (3) Put the ball mill jar in a planetary ball mill, and work for 24 hours at normal temperature and pressure with a rotating speed of 250 rpm;

[0035] (4) Take out the ball milling tank, pour out the solution insi...

Embodiment 3

[0037] This embodiment 3 is to solidify the heavy metals in the fly ash of the waste incineration of the grate furnace, which specifically includes the following steps:

[0038] (1) Get 5g of waste incineration fly ash under the grate furnace incineration mode, dissolve it in 80ml of deionized water, mix evenly, and make a mixed solution;

[0039] (2) Take the grinding balls so that the ratio of the total mass of the grinding balls to the solid mass of the waste incineration ash in the step (1) is 12, and add the grinding balls to the mixed solution prepared in the step (1). The grinding balls with the above total mass can be combined in the following manner: 21 small-sized grinding balls with a diameter of 6 mm, and 12 large-sized grinding balls with a diameter of 10 mm.

[0040] (3) Put the ball mill jar in the planetary ball mill, and work for 6 hours at normal temperature and pressure, with a rotating speed of 350rpm;

[0041] (4) Take out the ball milling tank, pour out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com