Spray-coating system for irregular workpieces

A technology for irregular workpieces, applied in the field of spraying systems for irregular workpieces, can solve problems such as poor spraying quality, low production efficiency, and personal injury, and achieve mass production, improve spraying quality, and ensure environmental requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

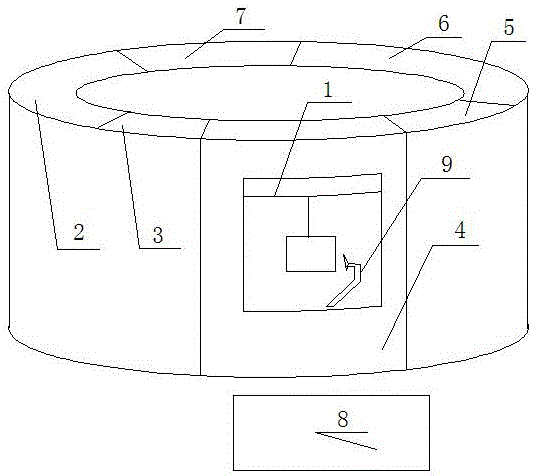

[0016] Such as figure 1 As shown, a spraying system for irregular workpieces, including a lifting line 1, a flushing chamber 2, entering a buffer chamber 3, a spraying chamber 4, leaving a buffer chamber 5, a paint baking chamber 6, a pendant operating chamber 7 and a control unit 8 The hoisting assembly line 1 is ring-shaped, and is located in the ring chamber formed by the ring connection of the air chamber 2, entering the buffer chamber 3, the spraying chamber 4, leaving the buffer chamber 5, the paint baking chamber 6, the pendant operation chamber 7, and the air chamber 2 In the middle; the spraying room 4 contains at least one spraying robot arm 9 with a mobile base, the control unit 8 includes a gesture remote controller and a control machine, and the gesture remote controller is manually operated outside the spraying room to instruct the spraying robot arm pair in the spraying room to be hoisted The first irregular workpiece sent by the assembly line is sprayed, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com