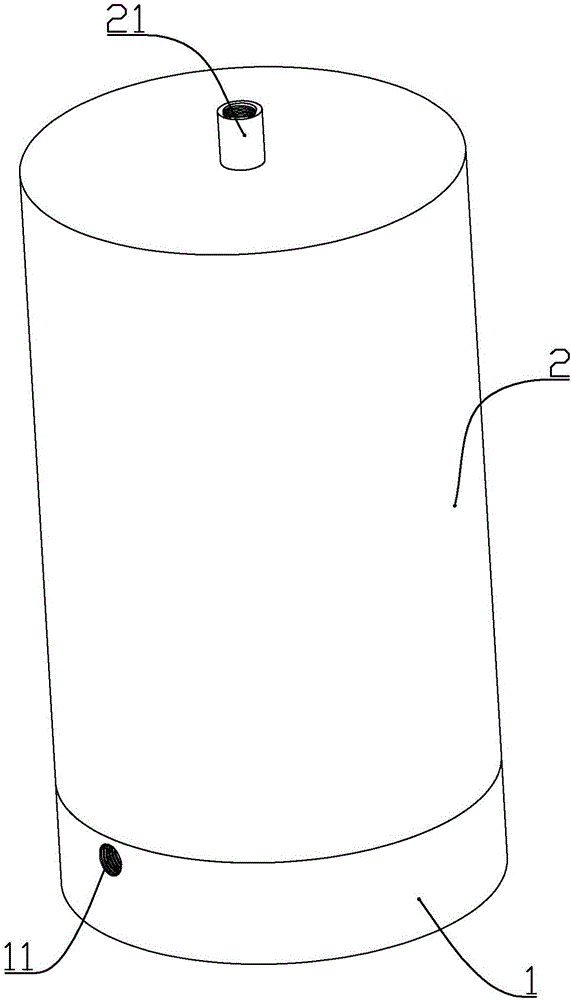

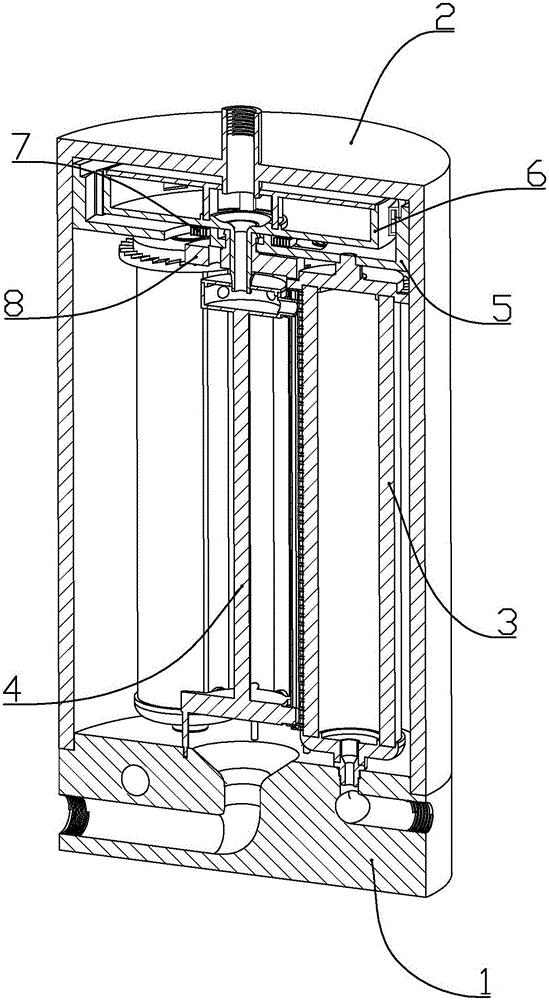

Large-flow ceramic filter element purification equipment

A technology of ceramic filter element and water purification equipment, which is applied in water/sewage treatment equipment, fixed filter element filter, filter separation, etc., and can solve problems such as troublesome operation, loss of ceramic filter element, and loss of filter element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0065] combine Figure 19 As shown, this embodiment is further improved on the basis of embodiment 1, the upper water inlet interface is connected to the tap water pipe, the non-drinking water interface is connected to the non-drinking water faucet through the pipe a, and the drinking water The interface is connected to the drinking water faucet through the pipe b; a pipe c is also connected between the pipe a and the tap water pipe, and a regulating valve is connected to the pipe c. The regulating valve is a manual regulating valve.

[0066] The non-drinking water faucet has two parallel water supply pipelines through the pipeline c. When the drinking water faucet draws less water, correspondingly, the dirt accumulated on the outer wall of the ceramic filter element is less, and the ceramic filter element does not need to be cleaned frequently. At this time Increase the effective opening of the manual regulating valve so that more water passes through the pipe c, so that the...

Embodiment 3

[0068] combine Figure 20 with Figure 21 As shown, this embodiment is further improved on the basis of Embodiment 1, the water inlet interface is connected to the tap water pipe, the drainage interface is connected to the non-drinking water faucet through the pipeline a, and the water outlet interface is connected through the pipeline b It is connected with a drinking water tap; a pipe c is also connected between the pipe a and the water pipe, and a regulating valve is connected to the pipe c. The regulating valve is an electric regulating valve; a flow sensor is connected to the pipeline b, the flow sensor is connected to the signal input end of the controller, and the electric regulating valve is connected to the output end of the controller; In the unit time, when the flow measured by the flow sensor is greater than the set value, the controller controls the electric control valve to reduce the opening; in the set unit time, when the flow measured by the flow sensor is le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com