Partitioned stator type hybrid excitation motor

A hybrid excitation motor and stator technology, which is applied in the fields of motors and electrical engineering, can solve the problem of the contradiction between the installation space of the excitation winding and the armature winding, and achieve the effect of improving the power density, reducing the influence and the characteristics of high power density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

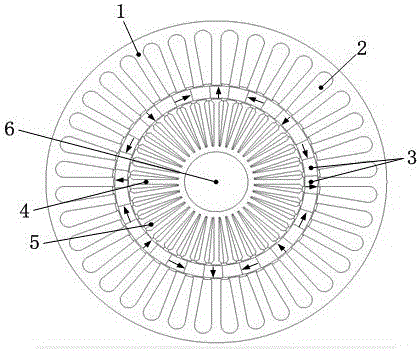

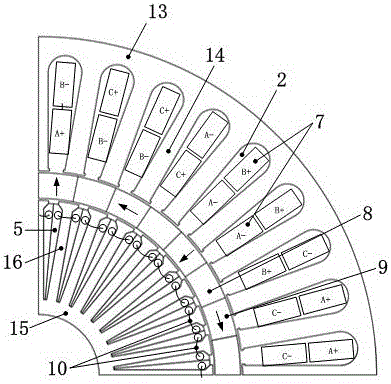

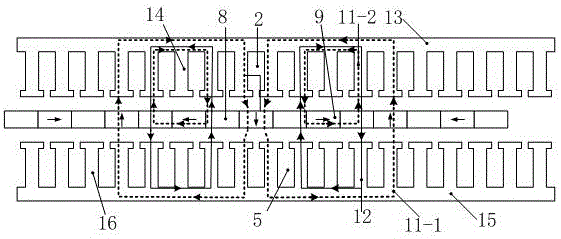

[0019] see figure 1 , The present invention provides a partitioned stator hybrid excitation motor, which includes an outer stator 1 , an intermediate rotor 3 , an inner stator 4 and a rotating shaft 6 in sequence from outside to inside. Outside the rotating shaft 6 is an inner stator 4 , an intermediate rotor 3 and an outer stator 1 coaxially arranged in sequence from the inside to the outside. The intermediate rotor 3 is coaxially installed inside the outer stator 1, and there is an outer air gap between the inner wall of the outer stator 1 and the outer wall of the intermediate rotor 3; the inner stator 4 is coaxially installed inside the intermediate rotor 3, and the inner wall of the intermediate rotor 3 and the outer wall of the inner stator 4 There is also a layer of inner air gap between them. There is a slot in the center of the inner stator 4 for installing the rotating shaft 6 . The intermediate rotor 3 is driven to rotate by the rotating shaft 6 . The thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com