64-channel polymer lithium-ion battery formation clamp machine

A lithium-ion battery and polymer technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., to reduce costs, reduce transfer processes, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

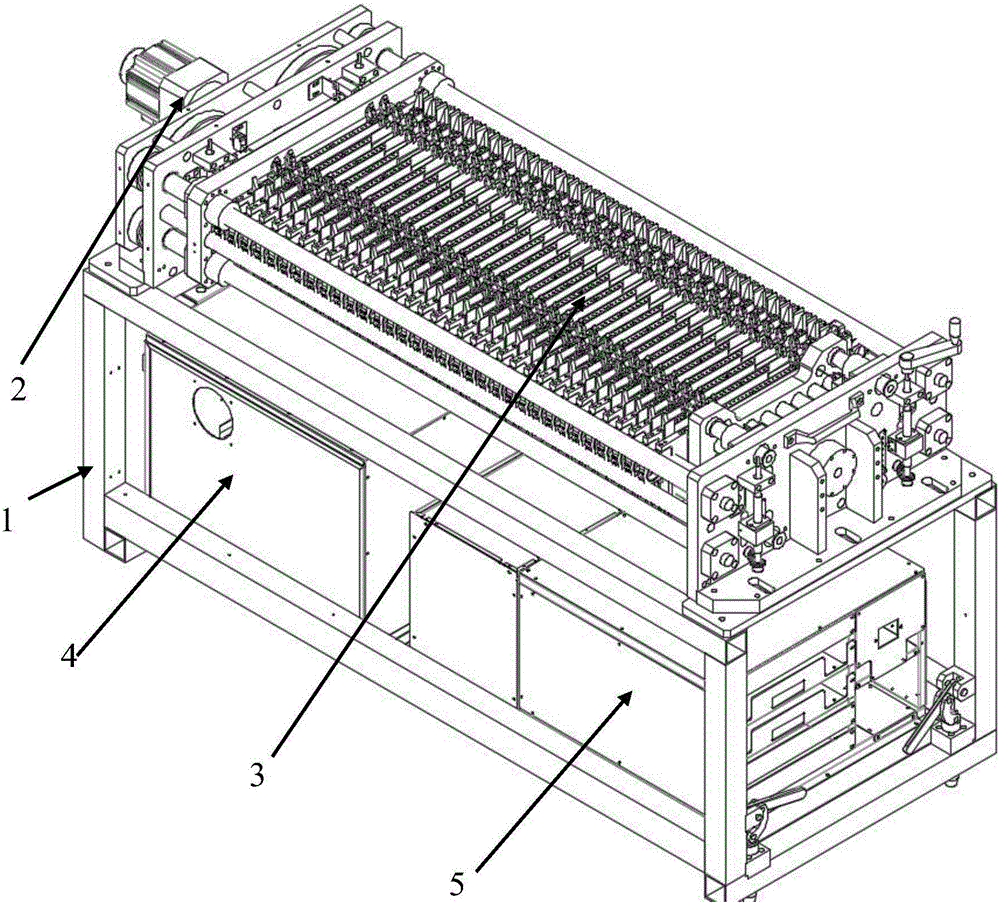

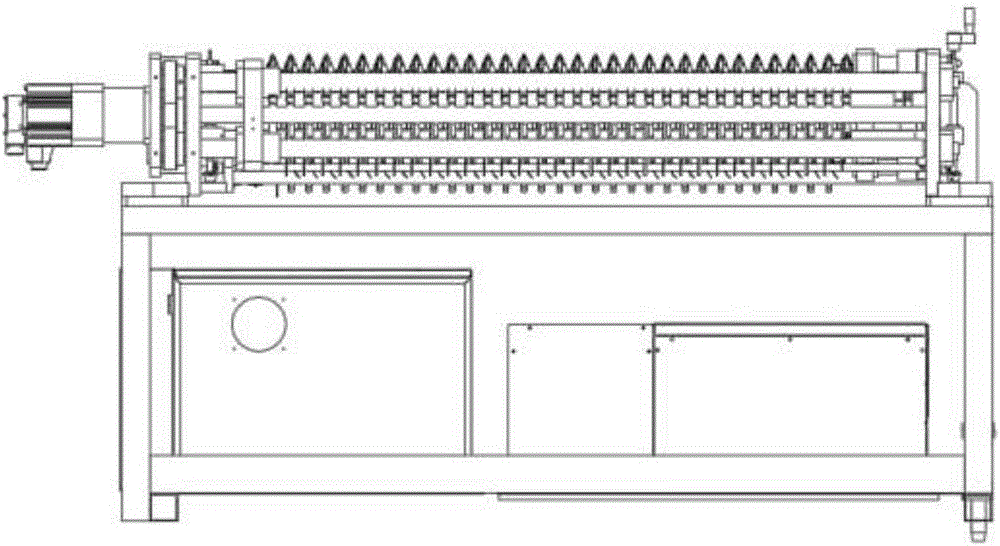

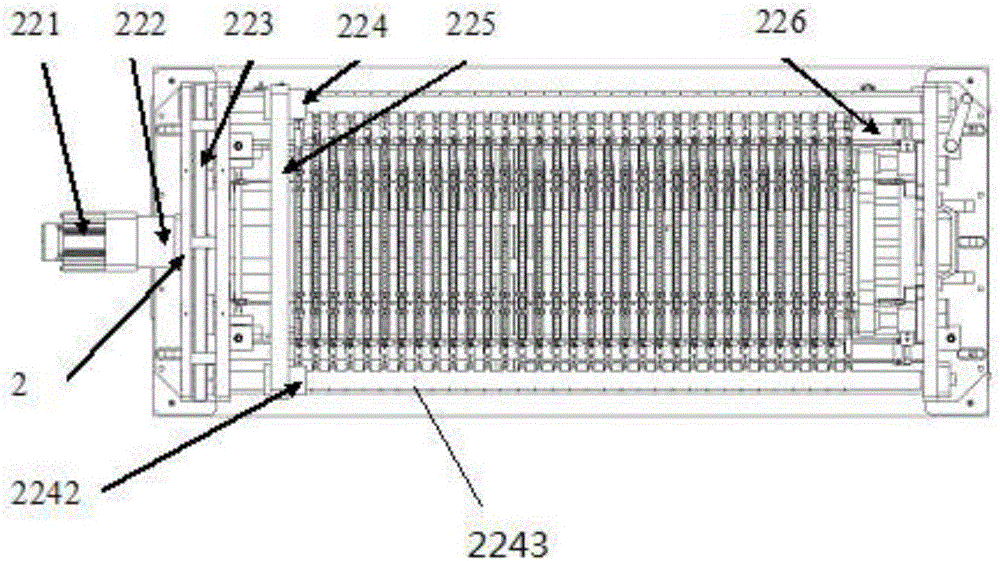

[0031] refer to Figure 1 to Figure 8 , 64-channel polymer lithium-ion battery formation fixture machine, including a frame 1, and also includes a pressure control device 2, a 64-channel laminate 3, a temperature control cabinet and a battery formation cabinet 4; the pressure control device 2 is installed on the On the frame 1, the 64-channel laminate 3 is installed on the pressure control device 2; the 64-channel laminate 3 includes a heating plate 31, a clamp plate 32, a temperature sensor 33, a connecting chain 34, Silicone plate 36 and battery tab contact pins for clamping the tabs of the polymer lithium-ion battery. Several clamp pressing plates 32 are arranged in parallel with each other, and the polymer lithium ion is clamped between them. Battery; the said heating plate 31 is attached on the surface of the said fixture pressing plate 32 for clamping the polymer lithium ion battery, and said silica gel plate 36 is attached on the surface opposite to the setting of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com