Method for calculating air intake volume of front-end module of car engine cabin

An engine compartment and front-end module technology, which is applied in calculation, design optimization/simulation, special data processing applications, etc., can solve the problems of high test cost, long analysis period, large workload, etc., and achieve the effect of short calculation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method for calculating the air intake volume of the front-end module of the automobile engine compartment of the present invention comprises the following specific steps:

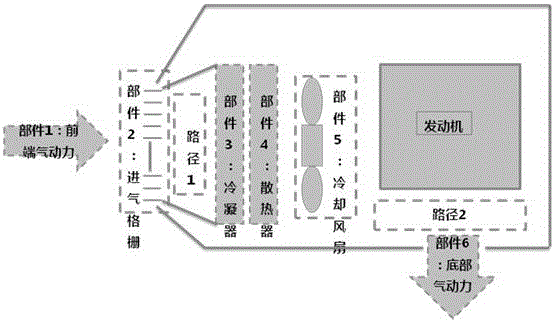

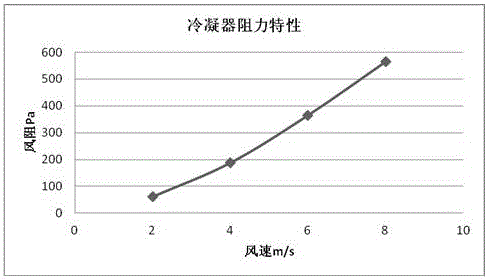

[0033] A. If figure 1 , 2 , define the air intake system of the front-end module of the engine compartment, and divide the entire front-end intake channel of the engine compartment into 6 parts and 2 paths according to the flow characteristics, including: Part 1: front-end aerodynamic force of the car; Part 2: front-end air intake grid Grille; Path 1: Passage between the intake grille and the condenser; Part 3: Condenser; Part 4: Radiator; Part 5: Cooling fan; Path 2: Passage between the cooling fan and the bottom of the engine compartment; Part 6: The aerodynamic force at the bottom of the car engine compartment. Define component 1, the aerodynamic force at the front end of the car, and component 5, the cooling fan, as power source components, and define other components and paths as resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com