Side anchor mouth curved surface element generation design method

A design method and edge anchor lip technology, applied in the directions of calculation, image data processing, special data processing applications, etc., can solve the problems of unable to meet the design requirements of various ship types at the same time, prolonging the design cycle, ignoring the processing difficulty and manufacturing errors, etc. Achieve the effect of shortening the design cycle, accurate design, and broad practical application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment takes a certain ship type as an example to further illustrate the method of the present invention:

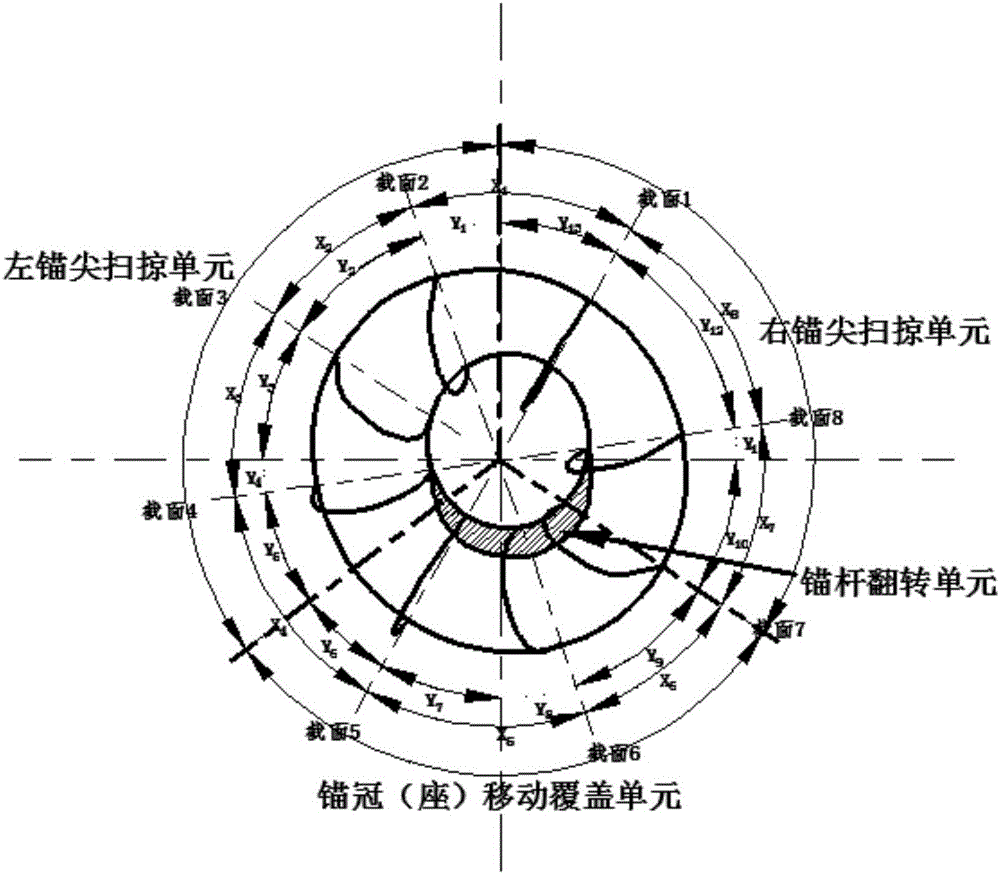

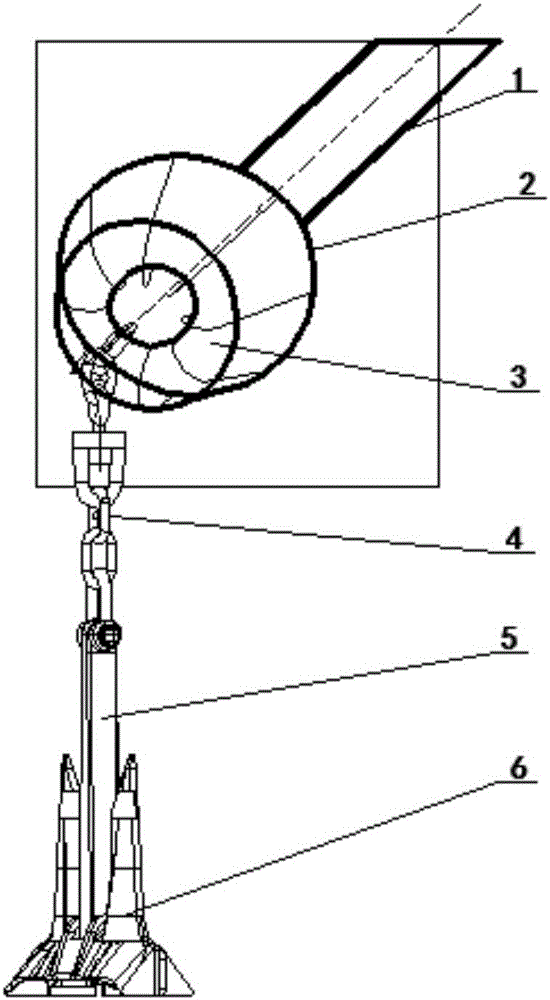

[0044] (1) According to the contact type between the anchor rod 5, the anchor crown (seat) 6 and the anchor lip 3 during the anchor pulling movement, the anchor lip 3 is divided into four regional units: the left anchor tip sweep area unit, the right anchor tip sweep area unit, and the anchor tip sweep area unit. The sweeping area unit, the 5 flipping area unit of the anchor rod, and the 6 moving coverage area unit of the anchor crown (seat), specifically include the following steps:

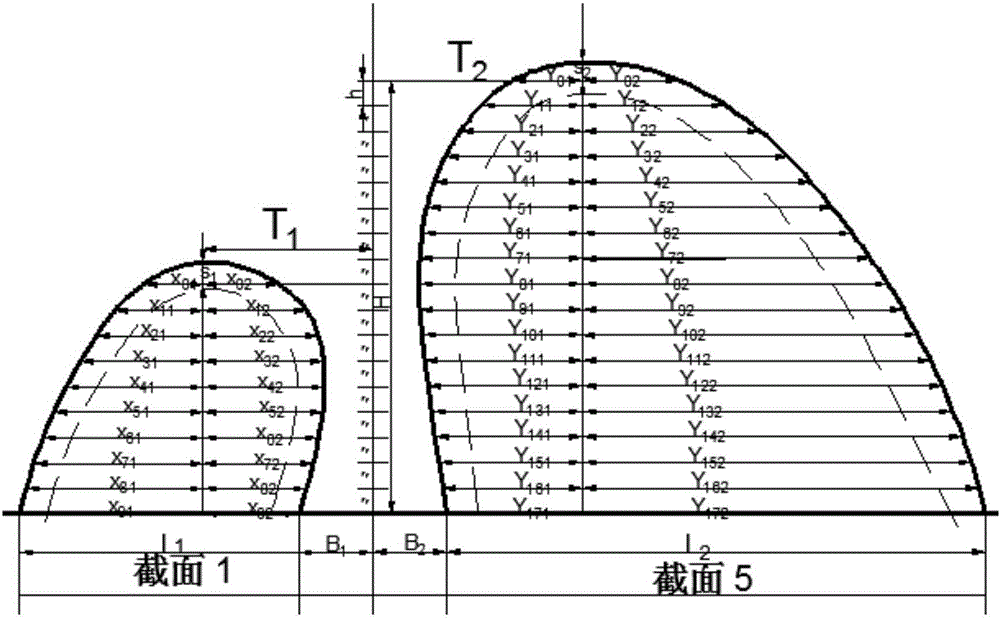

[0045](1.1) According to different ship types, the anchor lip 3 is firstly divided into sections, and they are respectively divided into the first section to the eighth section according to the counterclockwise rotation direction. The relative arrangement positions of the eight sections on the anchor lip 3 are controlled by angles: the first Angle X between the secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com