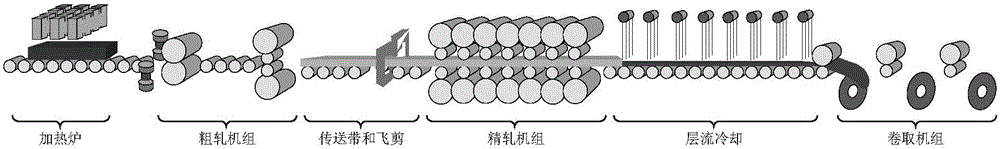

Quality fault locating method based on federated data driven production process

A fault location and production process technology, applied in the direction of instruments, electrical testing/monitoring, control/regulation systems, etc., can solve problems such as complex and rough fault evolution process, uncertain fault location and direction of change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

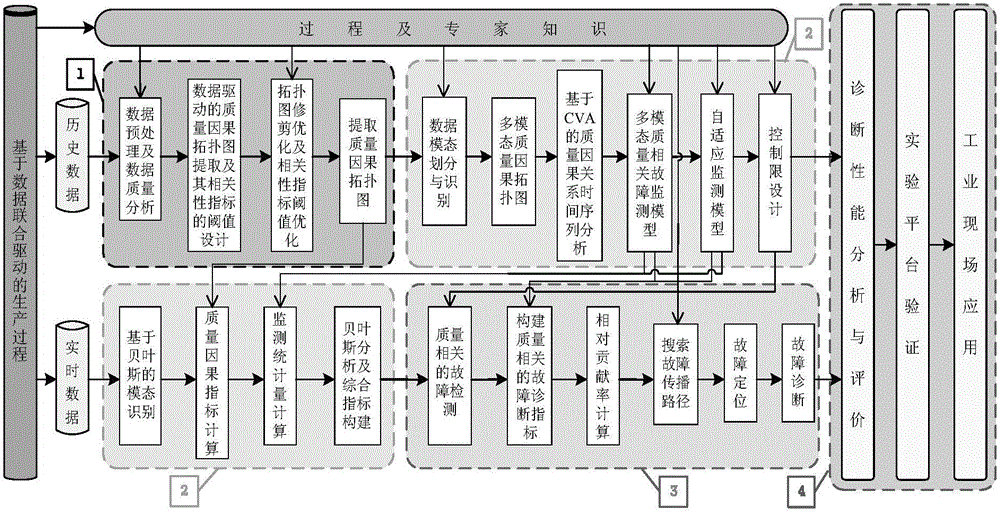

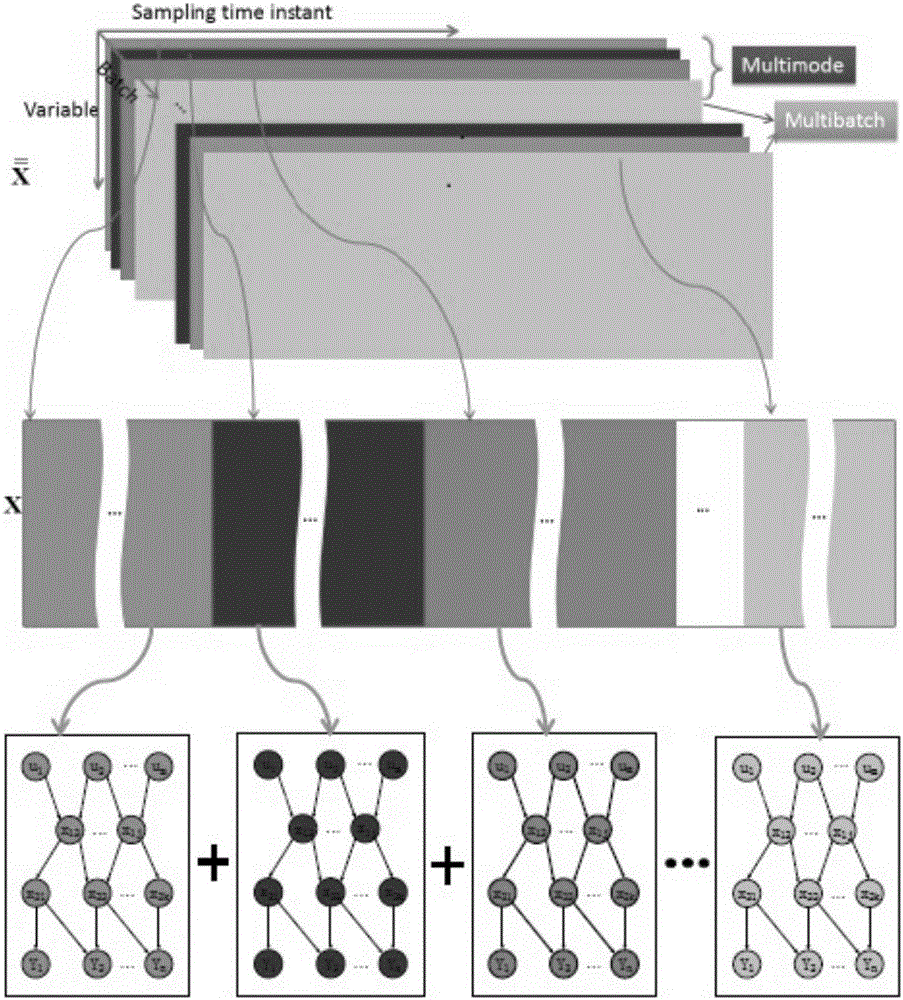

[0044] Aiming at the joint data-driven production process, the present invention proposes a method for locating quality faults, and strives to overcome the lack of rough description of the process in the existing data joint drive method. The present invention follows the research route of "quantitative-qualitative-quantitative" , using a joint data-driven method based on data and knowledge, deeply studied the correlation characteristics between variables, accurately revealed the quality-related faults, that is, the propagation path and fault source of quality faults, and realized the accurate positioning of quality-related faults, so as to achieve quality Early detection, diagnosis and maintenance.

[0045] The present invention will be further described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com