Embedded piezoresistive micro stress sensor

A stress sensor, embedded technology, applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problems of large size, unable to meet the requirements of solid engine interface stress measurement, etc., to achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

[0020] According to the deficiencies of the existing domestic stress sensor technology, the present invention provides a piezoresistive-based embedded miniature stress sensor, which is used to measure the interface stress or internal stress of a solid engine that requires a small volume of the embedded or embedded stress sensor.

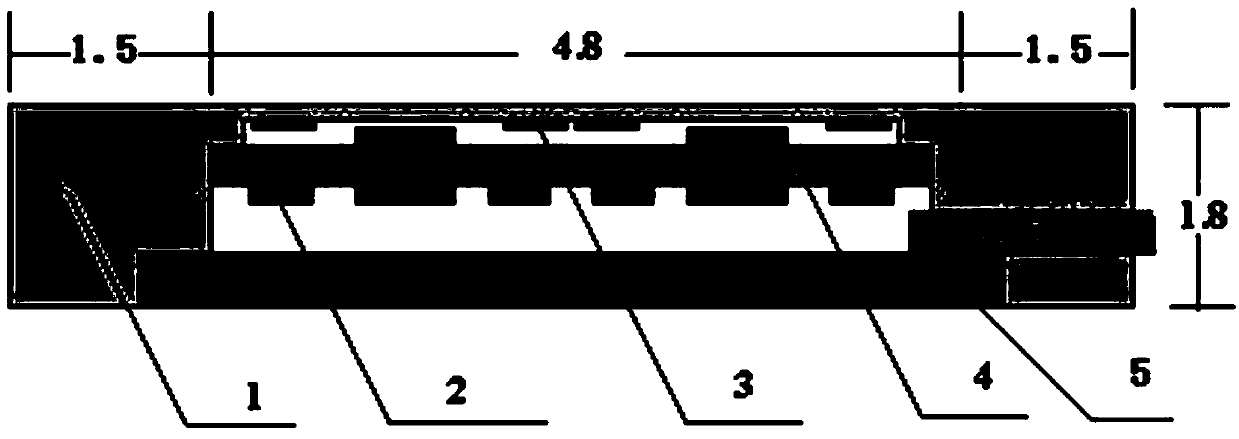

[0021] Such as figure 1 As shown, the miniature stress sensor of the present invention is a flat cylindrical structure as a whole, which is composed of a shell, a chip resistor, a sensitive element, a printed electrode, and a bottom plate. The shell is composed of a ring structure with a thickness of 1.8mm and a diameter of 7.8mm and a stainless steel circular diaphragm embedded and fixed at one end of the ring structure; the sensiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com