A variable stiffness parallel flexible constraint micro-nano probe

A technology of variable stiffness and parallel connection, applied in the field of measuring instruments, can solve problems such as slow dynamic response, damage to the surface of the tested component, and large measuring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

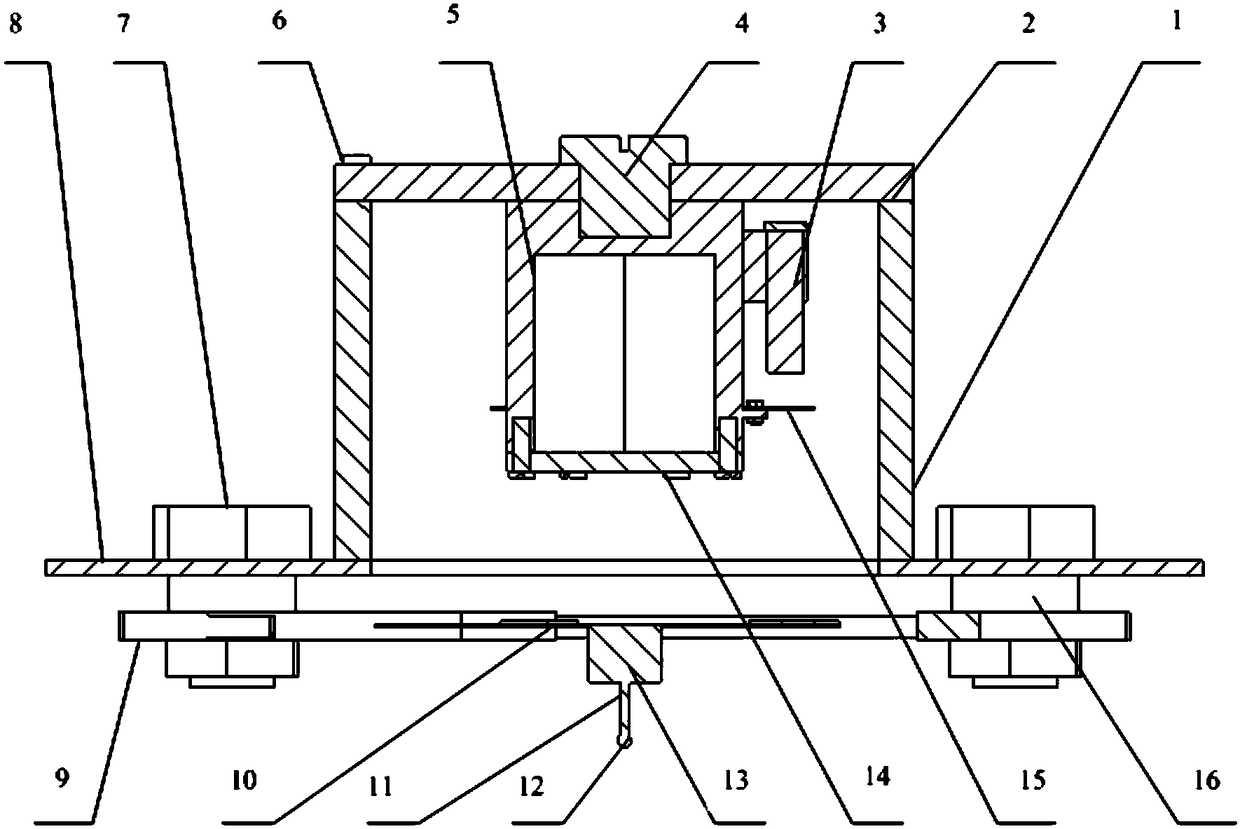

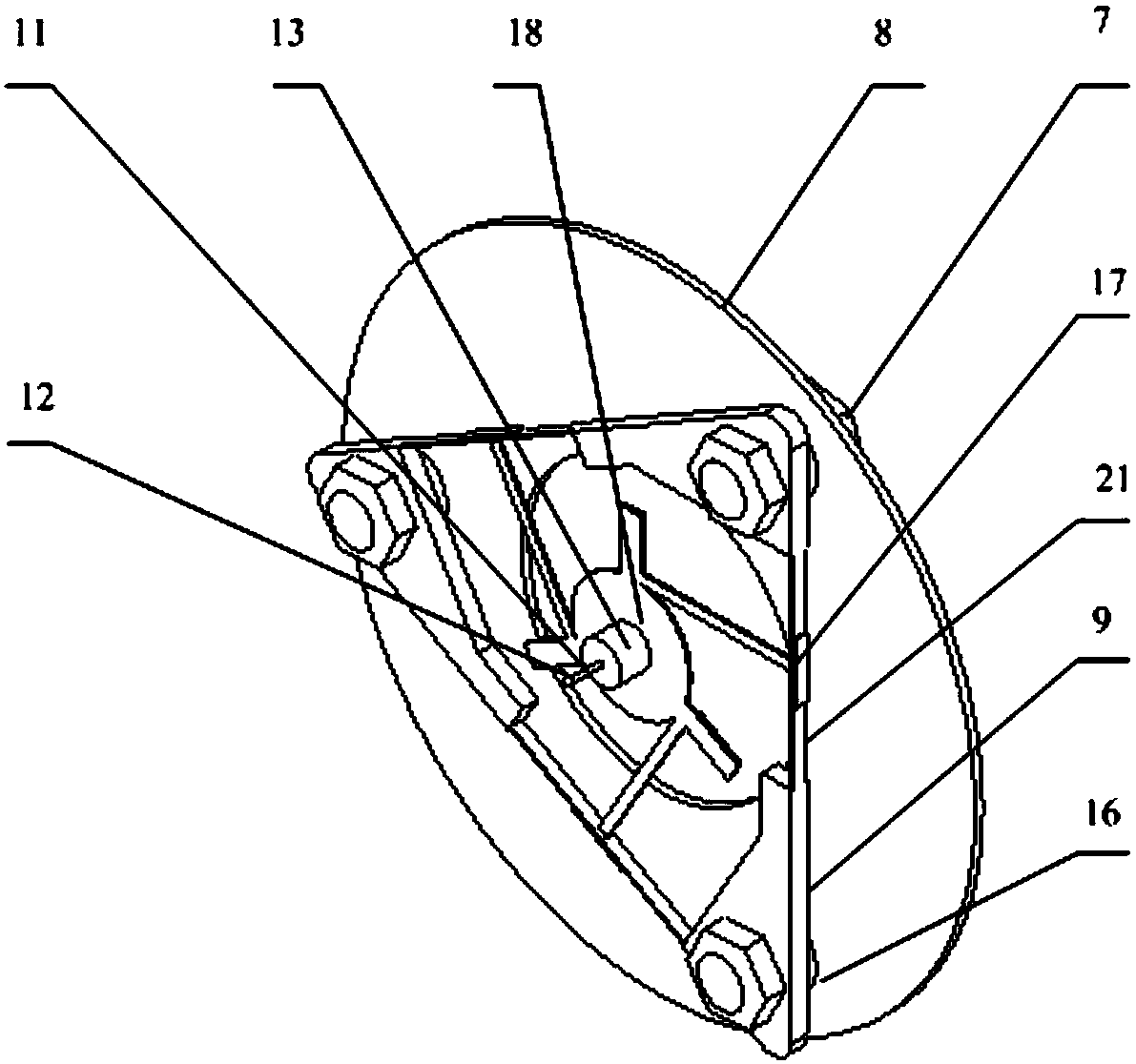

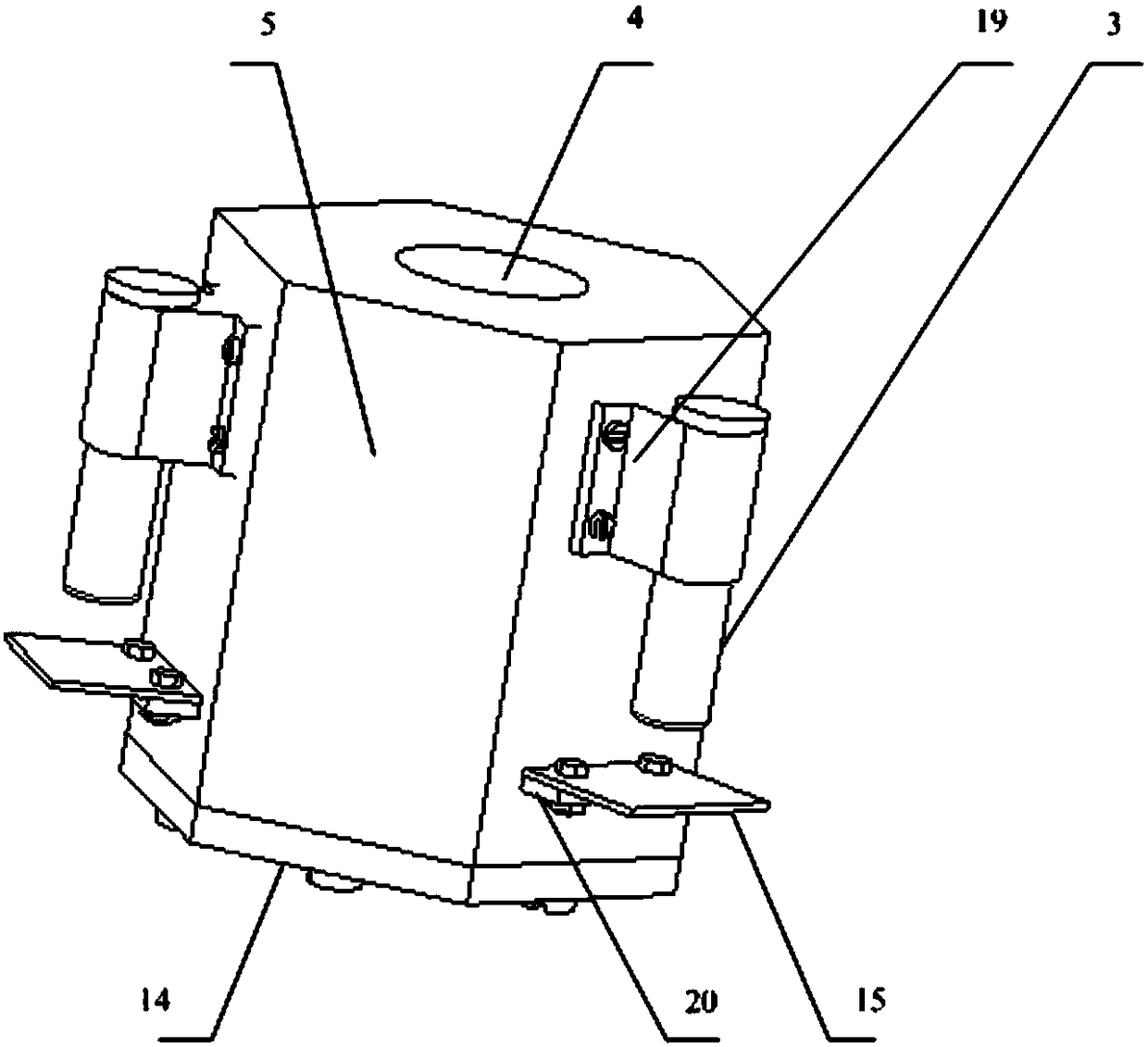

[0015] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

[0016] like Figures 1 to 4 As shown, a variable stiffness parallel flexible constrained micro-nano probe of the present invention includes an annular shell 1, the top of the shell 1 is provided with an upper end cover 2, and four edges of the upper end cover 2 are evenly distributed for connecting with the shell 1. Threaded hole I6, the center of the upper end cover 2 is provided with a threaded hole II4 for lifting the loaded object 5, the inner center of the upper end cover 2 passes through the threaded hole II4 to lift the loaded object 5, and the loaded object 5 is located in the cavity surrounded by the shell 1, The carrier 5 is a hollow regular hexagonal prism, which reduces the weight of the overall structure of the present invention.

[0017] Three laser interferometers 3 are evenly distributed on the side wall of the carrier 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com