Sanitary insert unit

A sanitation embedding and inflow side technology, which is applied to indoor sanitation plumbing installations, water supply installations, buildings, etc., can solve the problems of color distinction interference, manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

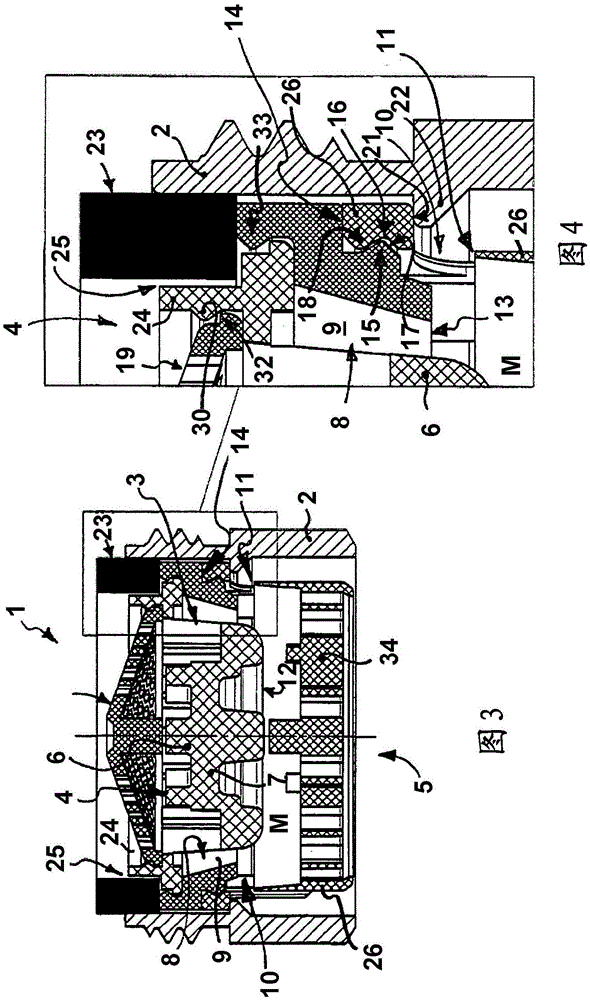

[0024] exist figure 1 and 2 And 3 to 6 show two different embodiments of the sanitary insertion unit 1 . The sanitary insertion unit 1 can be inserted into a sleeve-shaped spout 2 , which can be fitted on a water outlet of a water tap, not further shown here. The sanitary insert unit 1 has a jet regulator 3 , which is designed here as an air-filled jet regulator. The jet regulator 3 has a jet regulator housing whose inflow-side housing end face forms the housing inlet 4 and whose outflow-side housing end face forms the housing outlet 5 . A jet splitter 6 , which is designed here as a cup-shaped diffuser, is arranged in the jet regulator housing. The cup-shaped diffuser has a cup base 7 which serves as an impact surface for deflecting the passing water outwards. The cup-shaped diffuser has in its cup-shaped peripheral wall at least one through-flow opening and preferably a plurality of through-flow openings 8 arranged at equal distances from one another, which open into an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com