Construction method and structure of underwater reinforced concrete combined suspension-box cofferdam free of bottom-sealing concrete

A technology of back-sealing concrete and construction methods, which can be applied in the direction of infrastructure engineering, construction, etc., can solve the problems such as the influence of the positioning effect of steel hanging boxes, the failure to promote and use it in China, and the impact on water-stopping effects, etc., and achieve good promotion and application value and scope of application wide, saving concrete and steel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

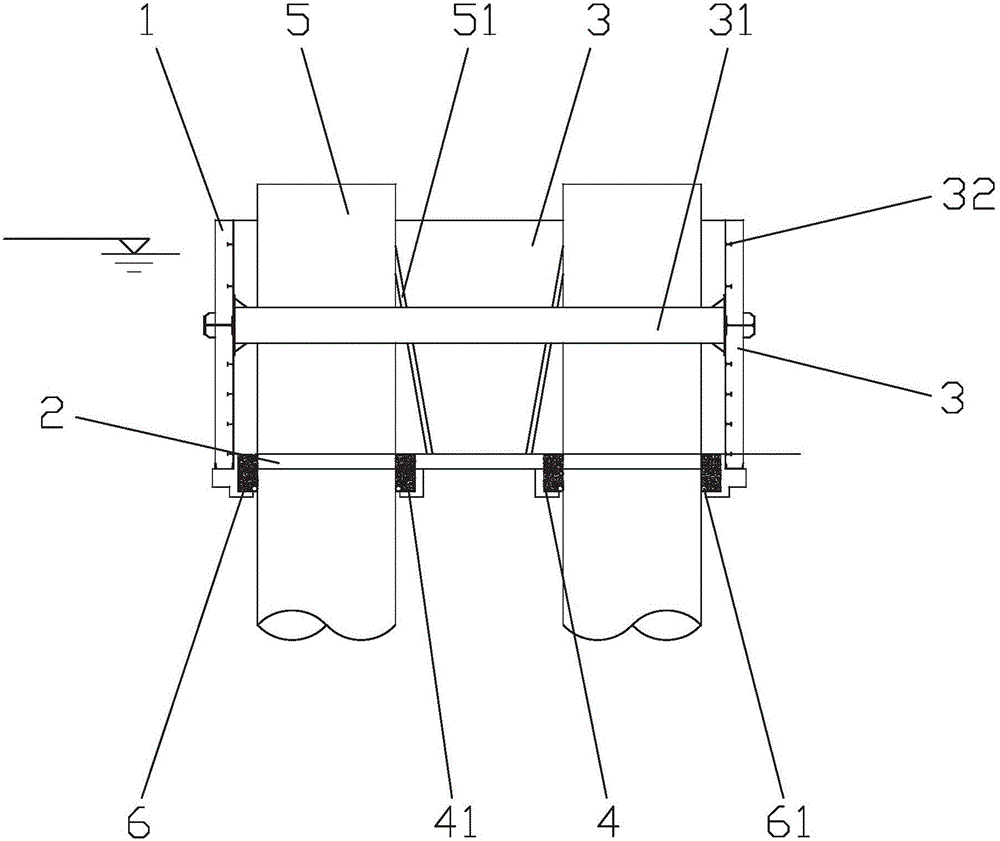

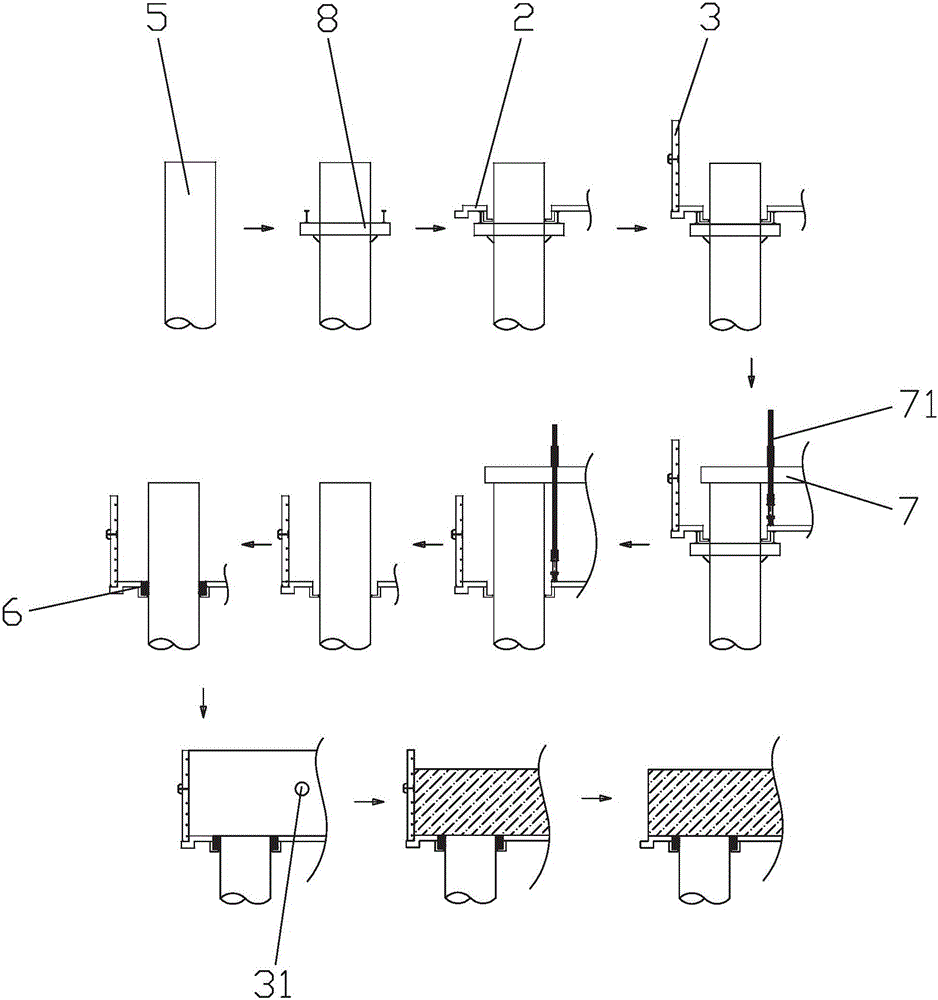

[0033] In order to make the purpose, technical solution and advantages of the present application clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. In the ensuing description some specific details are referred to for a thorough understanding of the present invention. While the present invention may still be practiced without these specific details, the descriptions and representations herein are used by those skilled in the art to effectively convey the substance of their work to others skilled in the art. refer to figure 1 , figure 2 , image 3 , an underwater construction method of a concrete-steel-concrete combination hanging box cofferdam without a bottom cover, comprising the following steps,

[0034] 1) After the pile foundation construction is completed, make the hanging box 1;

[0035] 2) Install the pole beam 7 and the continuous jack 71 on the casing 5 as the lowering device of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com