Fragrant antistatic synthetic leather

A synthetic leather and antistatic technology, applied in the field of synthetic leather, can solve the problems of poor durability, unsuitability, and short fragrance retention time, and achieve the effects of good heat retention and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

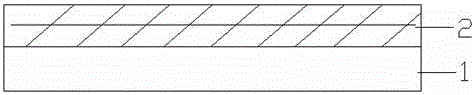

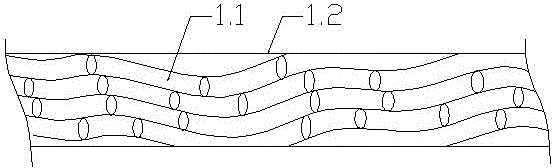

[0018] see Figure 1-2 , the present invention relates to a scented antistatic synthetic leather, which comprises a base layer 1 and a plastic surface layer 2 bonded to each other, the plastic surface layer 2 is composed of carbon fiber and PVC plastic, and the carbon fiber is vertically and horizontally distributed over the entire piece In the synthetic leather, several groups of micro-sachets 1.1 fixed by adhesive are arranged in the void of the base layer 1, and a waterproof layer is provided on the outside of each group of micro-sachets 1.1, and the outer surface of the base layer 1 is also coated with There is a fragrance control layer 1.2 for controlling the volatilization of fragrance in the microsachet 1.1.

[0019] Wherein, the fragrance control layer 1.2 is a pearlescent coating, which makes the fabric shiny; the microsachet 1.1 is a spherical particle, and the diameter of the microsachet 1.1 is 50 μm, and the spherical particle structure is simple, easy to be built,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com