Needle position structure of crank arm splicer

A patchwork sewing machine and articulating arm technology, which is applied in the direction of cloth pressing mechanism, cloth feeding mechanism, sewing machine components, etc., can solve the problems of insufficient gripping force, poor sewing, dense stitching, etc., and achieve stable feeding, The effect of stable feeding and smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with the accompanying drawings, the present invention will be further described with specific embodiments:

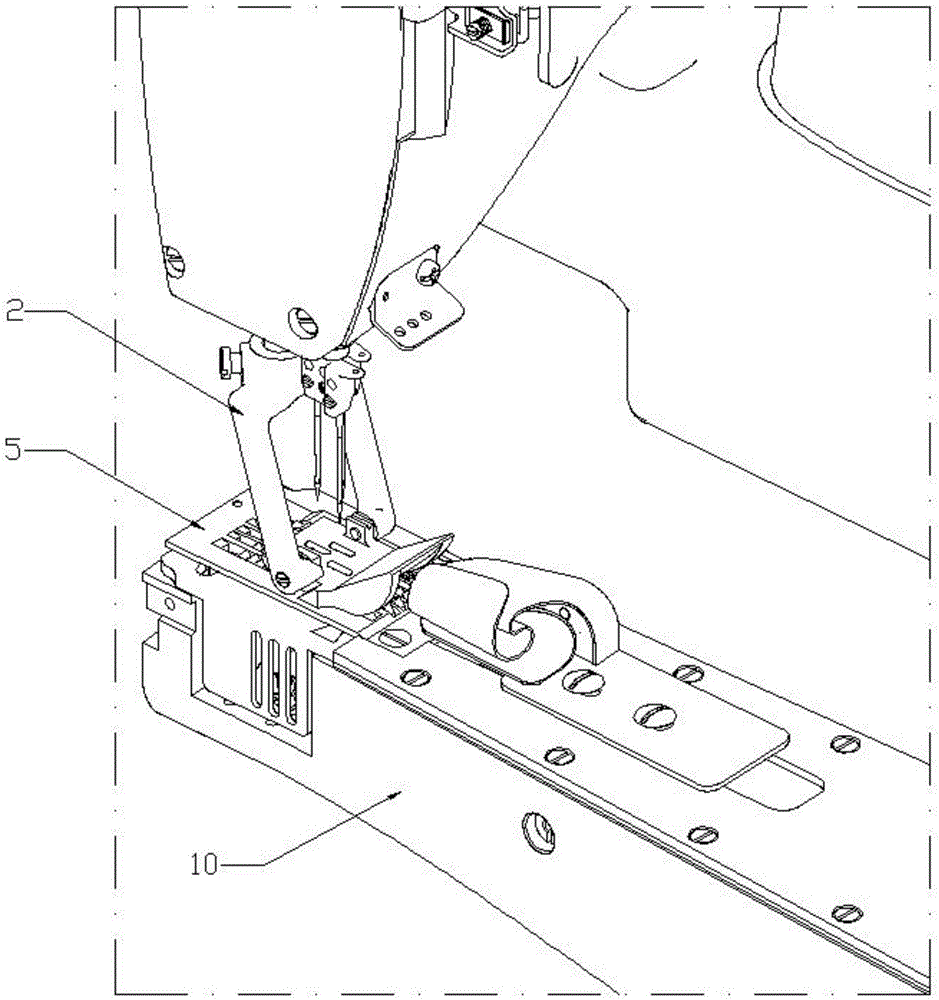

[0034] The up-down, front-rear positional relationship mentioned in the present invention is based on the Figure 7 shall prevail, Figure 7 The top is up, the bottom is down, the left is back, and the right is front.

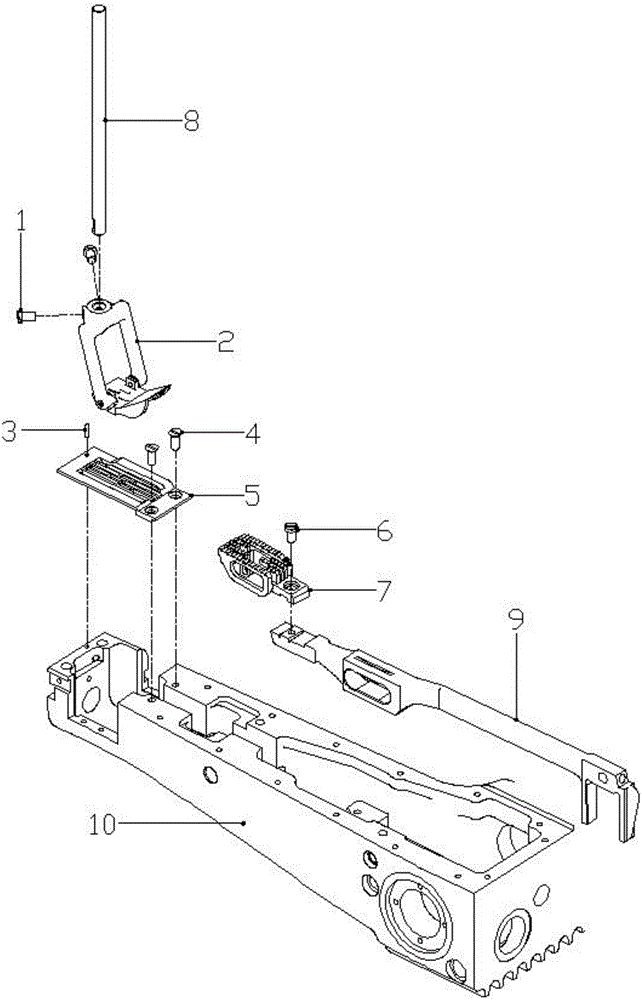

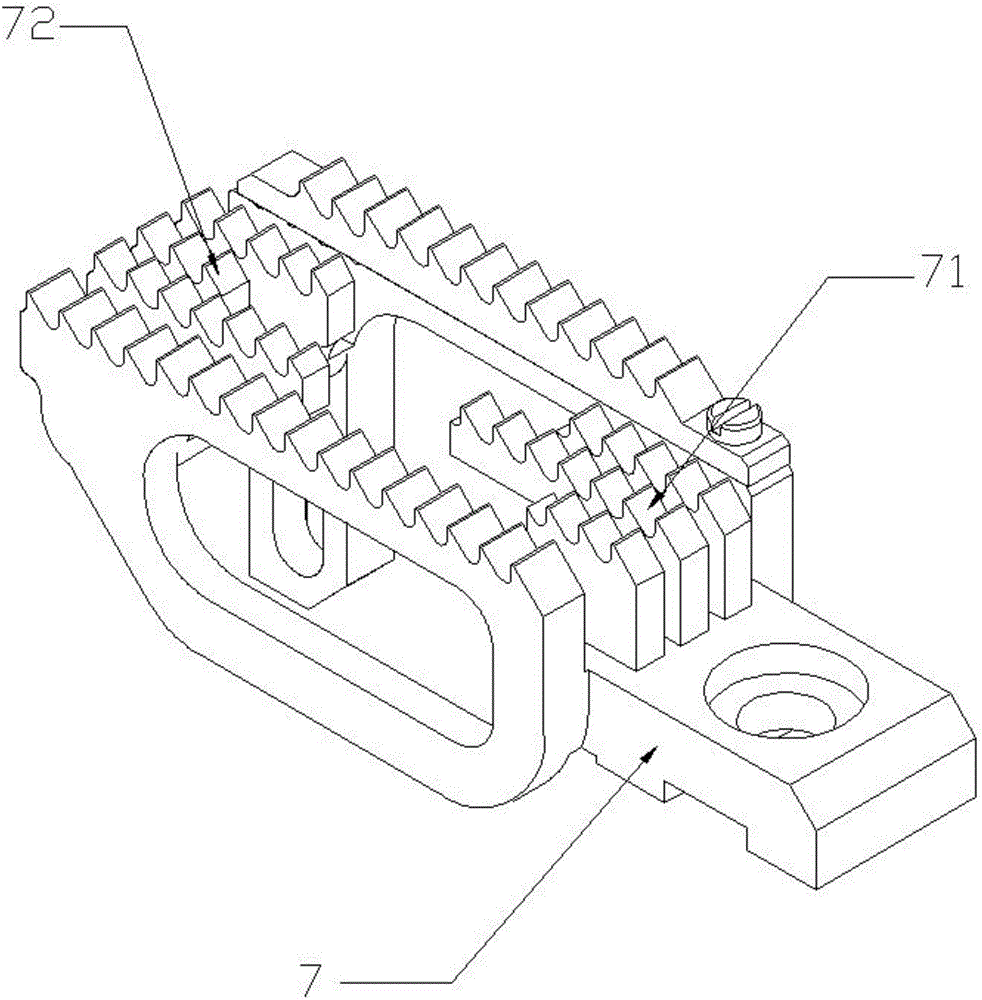

[0035] A needle position structure of a crank arm type sewing machine includes a presser foot rod 8, a presser foot 2, a needle plate 5, a feeding rod 9, and a cloth feeding tooth 7. The presser foot 2 is fixedly connected to the lower end of the presser foot rod 8, The presser foot rod 8 drives the presser foot 2 to reciprocate up and down. The needle plate 5 is fixed on the upper surface of the frame 10 below the presser foot 2. The cloth feeding tooth 7 is fixedly connected to the front end of the feeding rod 9. The cloth feeding tooth 7 The upper surface is provided with several rows of teeth, the needle plate is formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com