Beta-diketone organic barium-zinc PVC heat stabilizer and preparation method thereof

A heat stabilizer and diketone technology, applied in the field of β-diketone organic barium/zinc PVC heat stabilizer and its preparation, can solve the problems of difficult precipitation, poor lubricity, lower softening point of products, etc. Crystal, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

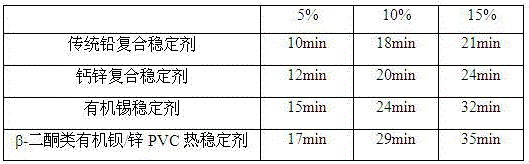

Image

Examples

Embodiment 1

[0021] Introduce nitrogen into the ultrasonic reaction vessel equipped with a stirring device, then add 300mL of dichloromethane solution dissolved in 22.5g (0.1mol) of 1,3-diphenyl-1,3-propanedione, and then add 100mL of ammonia water , slowly drop 300mL of methanol solution containing 10g (0.05mol) of barium chloride into the ultrasonic reaction vessel at a reaction temperature of 50°C, turn on the stirring device and ultrasonic generating device during the dropping process, and set the frequency of the ultrasonic generating device After the dropwise addition, the solution is in a clear state at this time, stop stirring, keep the ultrasonic generating device to continue to work, slowly cool down to 0°C, the reaction solution is still, open the vent hole on the ultrasonic reaction container, and keep the nitrogen gas flowing in Exhaust from the exhaust hole, let the nitrogen gas discharge out of the ultrasonic reaction vessel along with a certain amount of reaction solvent, an...

Embodiment 2

[0023] Introduce nitrogen into the ultrasonic reaction vessel equipped with a stirring device, then add 300mL of dichloromethane solution dissolved in 22.5g (0.1mol) of 1,3-diphenyl-1,3-propanedione, and then add 100mL of ammonia water Slowly add 300mL of methanol solution containing 20g (0.1mol) of barium chloride to the ultrasonic reaction container at a reaction temperature of 25°C. During the dropping process, turn on the stirring device and the ultrasonic generating device. The set frequency of the ultrasonic generating device is After the dropwise addition, the solution is in a clear state at this time, stop stirring, keep the ultrasonic generating device to continue to work, slowly cool down to 0°C, the reaction solution is still, open the vent hole on the ultrasonic reaction container, and keep the nitrogen gas flowing in Exhaust from the exhaust hole, let the nitrogen gas discharge out of the ultrasonic reaction vessel along with a certain amount of reaction solvent, a...

Embodiment 3

[0025] Introduce nitrogen into the ultrasonic reaction vessel equipped with a stirring device, then add 300mL of dichloromethane solution dissolved in 22.5g (0.1mol) of 1,3-diphenyl-1,3-propanedione, and then add 100mL of ammonia water , slowly drop 300mL of methanol solution containing 14g (0.1mol) of zinc chloride into the ultrasonic reaction vessel at a reaction temperature of 25°C, turn on the stirring device and the ultrasonic generating device during the dropping process, and set the frequency of the ultrasonic generating device After the dropwise addition, the solution is in a clear state at this time, stop stirring, keep the ultrasonic generating device to continue to work, slowly cool down to 0°C, the reaction solution is still, open the vent hole on the ultrasonic reaction container, and keep the nitrogen gas flowing in Exhaust from the exhaust hole, let the nitrogen gas discharge out of the ultrasonic reaction vessel along with a certain amount of reaction solvent, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com