Volatile insulation box for cooling and insulation of cold fresh product

An insulated box and product technology, applied in the direction of insulated containers, household refrigeration devices, packaging items, etc., can solve the problems of short heat preservation time and no cooling function, and achieve long heat preservation time, low use cost and high manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

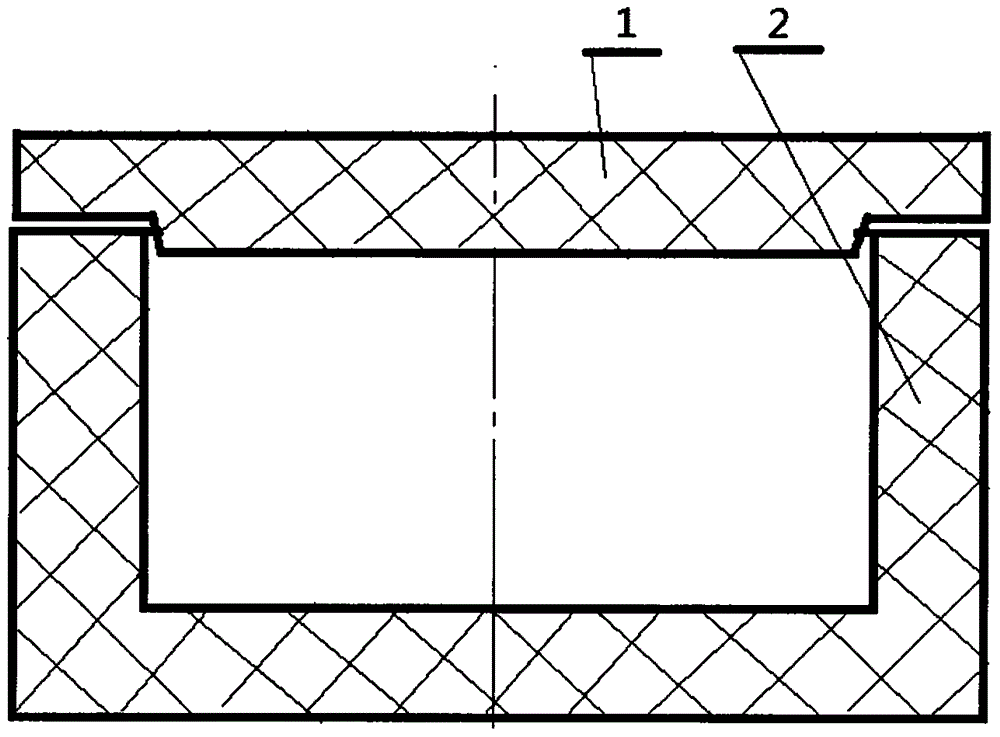

[0010] exist figure 1 Among them, the box cover (1) and the box body (2) are molded by a molding machine to suppress the foam that absorbs water and volatilizes water. The case cover (9) is covered on the casing (10), and the case cover is opened freely during use, and becomes a disposable volatilization incubator on the alignment cover.

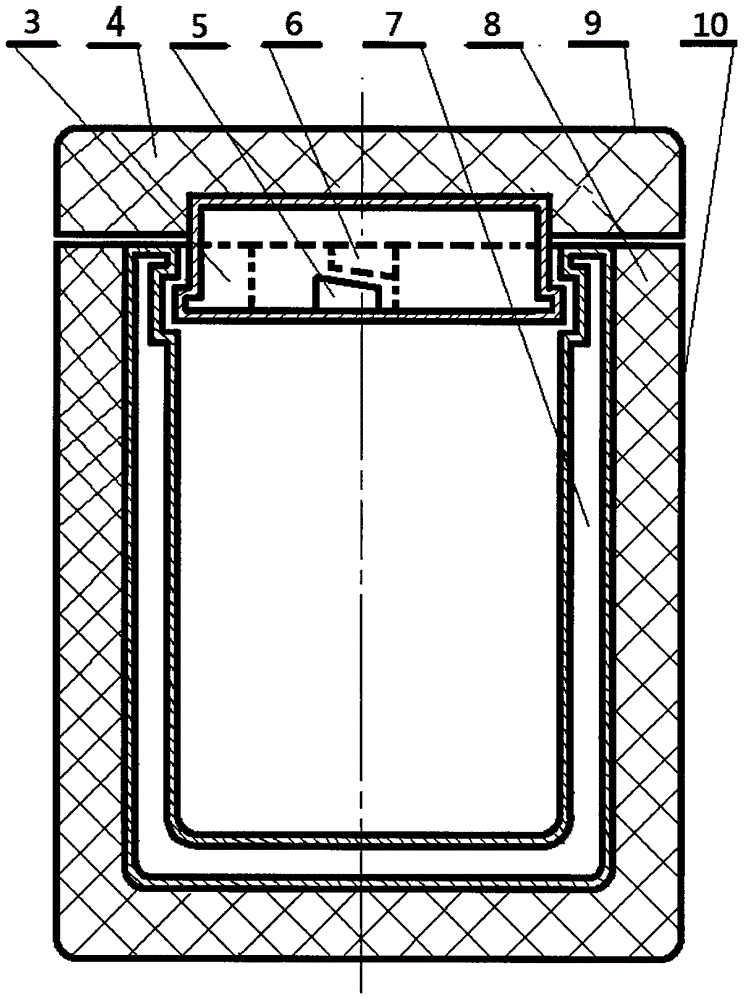

[0011] exist figure 2 Among them, the box cover vacuum liner (3) and the foam wrapping cover (4) absorbing water and volatile water are pressed into a vacuum box cover (9) by a molding machine. The box body vacuum liner (7) and the foam wrapping box (8) absorbing water and volatilizing water are pressed into a vacuum box body (10) by a molding machine. Rotating the vacuum box cover (9) connects the vacuum box (10) together by pressing the convex threaded button (5) on the box cover vacuum liner and the concave threaded button (6) pressed on the box body vacuum liner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com