Pen point combing robot

A technology of robots and nibs, applied in the repair of ink pens, nibs, writing utensils, etc., can solve the problems of waste of manpower and low efficiency of manual combing, and achieve high combing efficiency and uniform combing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

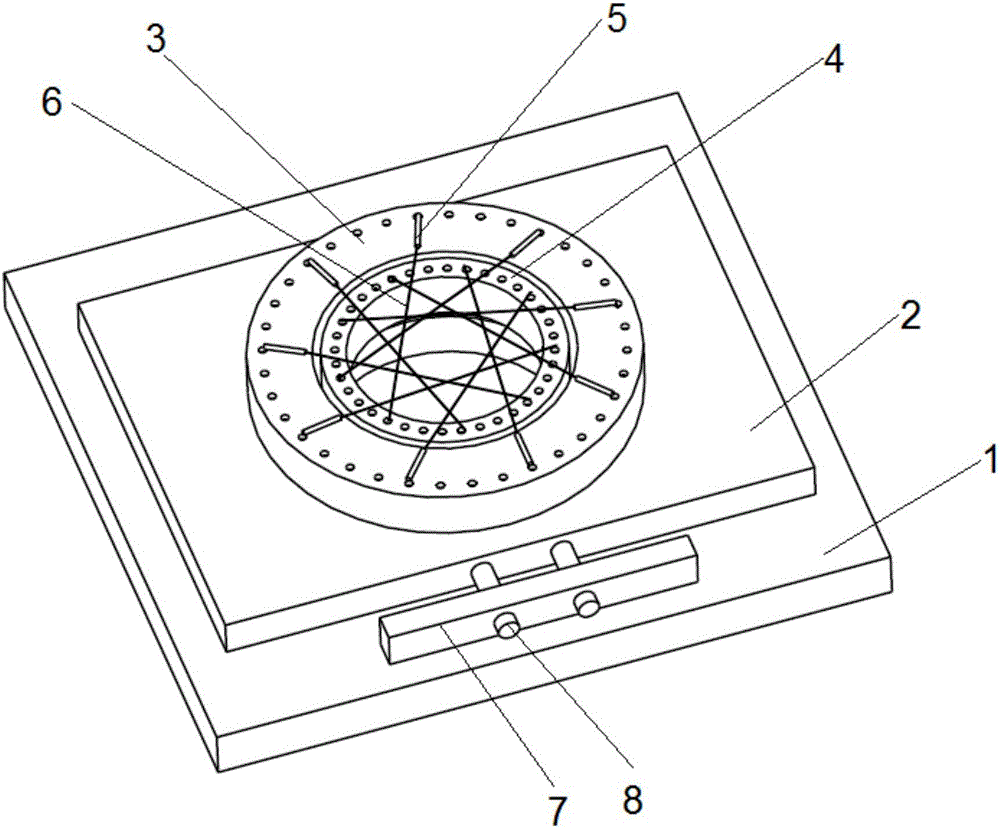

[0023] see figure 1 , a brush combing robot, has:

[0024] fixed disk;

[0025] The turntable is arranged in the middle of the fixed disk and can rotate;

[0026] A carding belt, the carding belt includes a spring and a rope, each of which has one end connected to each other, and the other two ends are respectively connected to the fixed disk and the rotating disk;

[0027] There are at least three groups of carding belts, which are distributed in different positions on the periphery of the fixed disk.

[0028] One end of the spring is connected to one end of the rope, the other end of the spring is connected to the fixed disk; the other end of the rope is connected to the turntable.

[0029] A through hole is arranged in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com