A handling robot equipped with a rotating manipulator

A technology of handling robots and rotating manipulators, which is applied in the field of handling robots, can solve the problems of heavy workload and difficulty in improving PCB board cutting efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

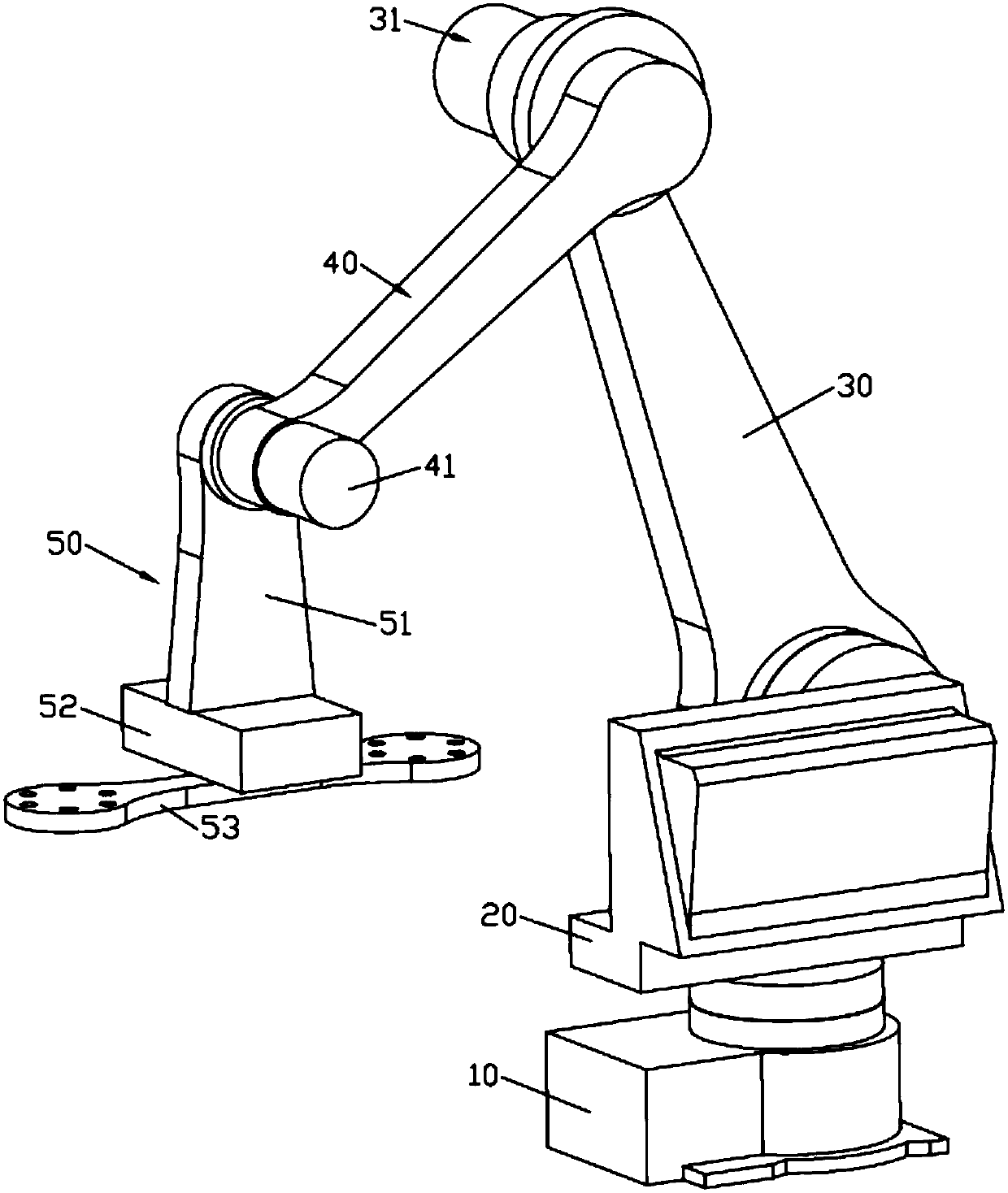

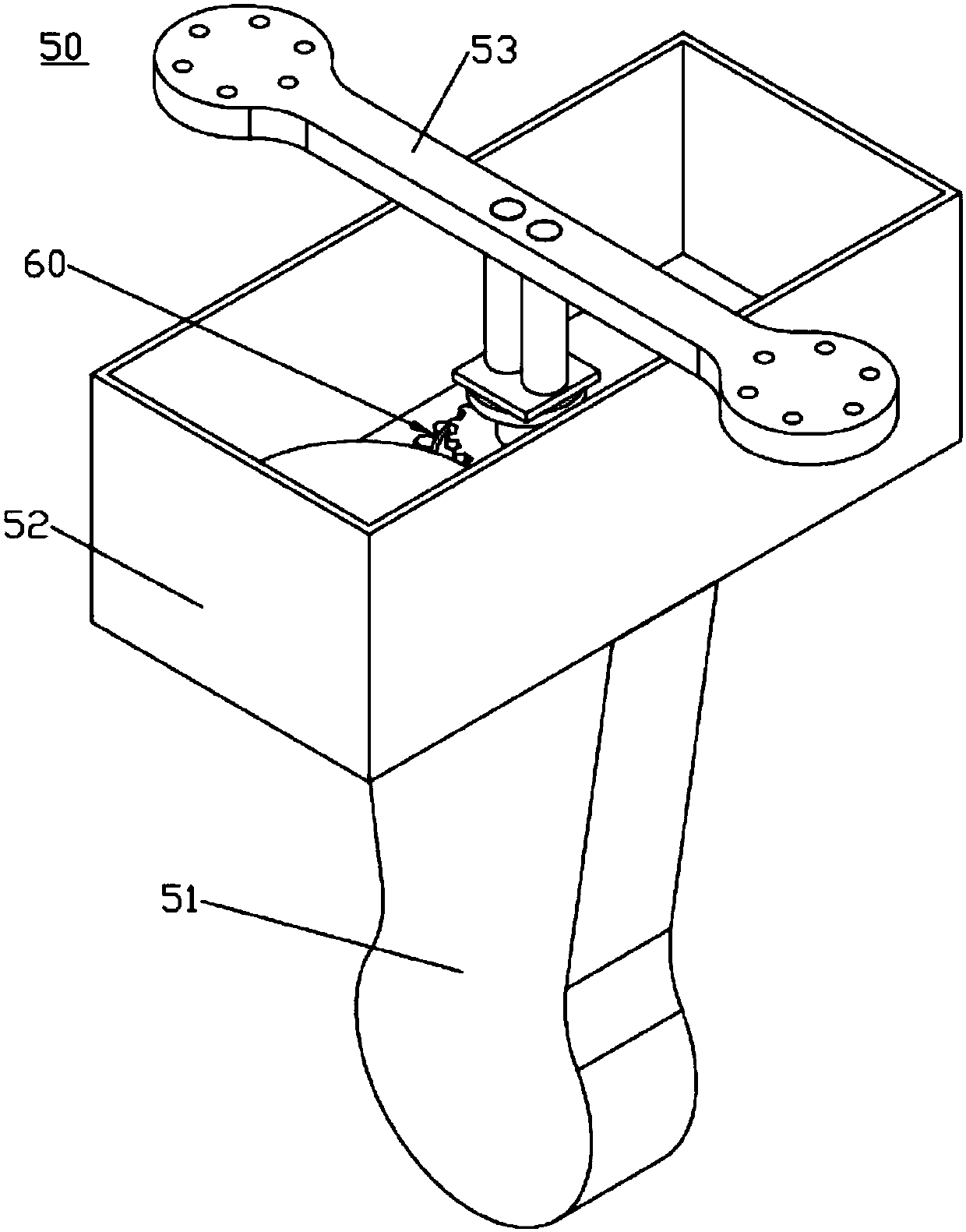

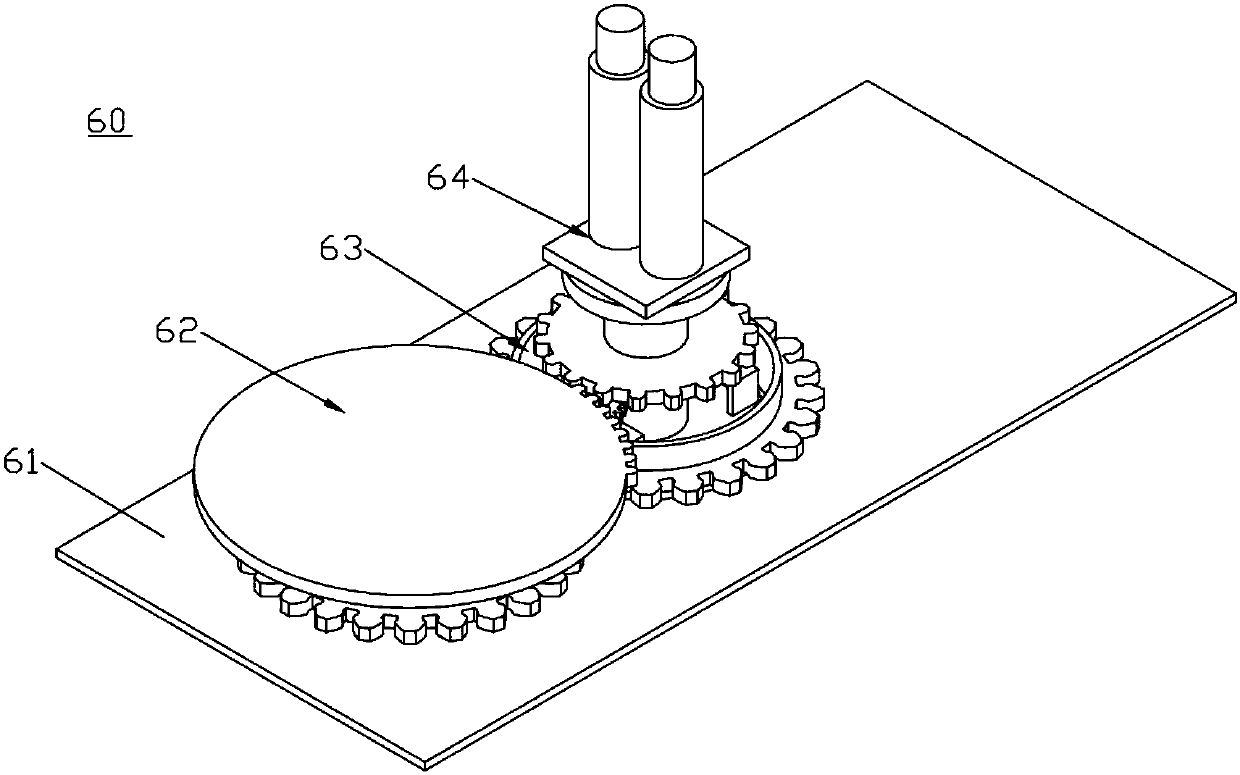

[0020] Such as Figure 1 to Figure 7 As shown, a transfer robot provided with a rotating manipulator includes a base body 10, a waist swivel part 20 pivotally connected to the base body 10, a boom 30 pivotally connected to the waist swivel part 20, and a boom 30 pivotally connected to the boom 30. The forearm 40 on the upper arm, the manipulator 50 installed on the forearm 40; The manipulator 50 includes a pair of suction cup groups, the drive mechanism 60 that drives the pair of suction cup groups to rotate; The drive mechanism 60 includes a base 61, a rotation drive device 62. Lock assembly 63 and rotation assembly 64; rotation assembly 64 includes a pair of positioning rods 641, a rotation support 642 and a first gear 643; the upper end of the rotation support 642 is fixed with a pair of positioning rods 641, and the middle is fixed with a first gear 643 , the lower end is pivotally connected to the base 61; the first gear 643 has a pair of limiting holes 6431; the lock ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com