Direct-driving stirring and transmission device

A transmission device and stirring shaft technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems of large working torque, large power consumption, and high failure rate, and achieve small working torque, The effect of low power consumption and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

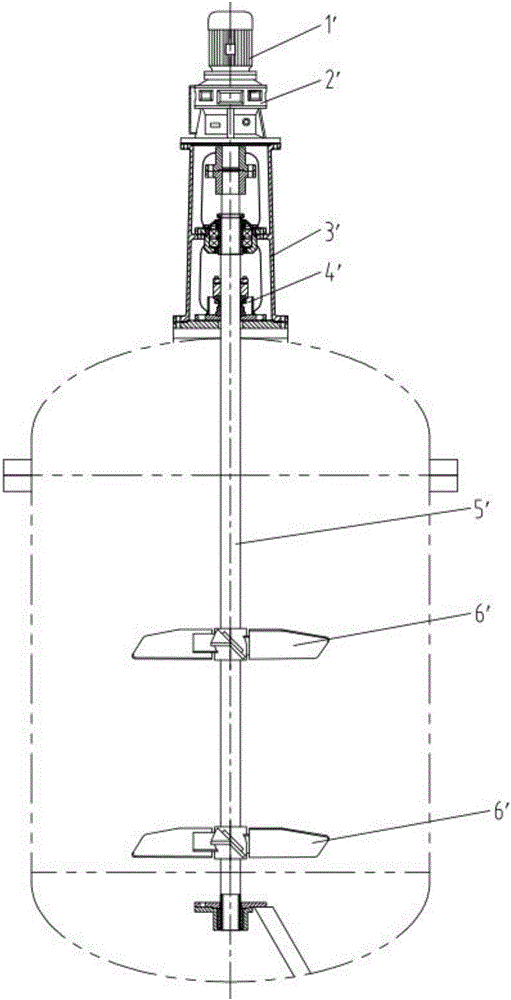

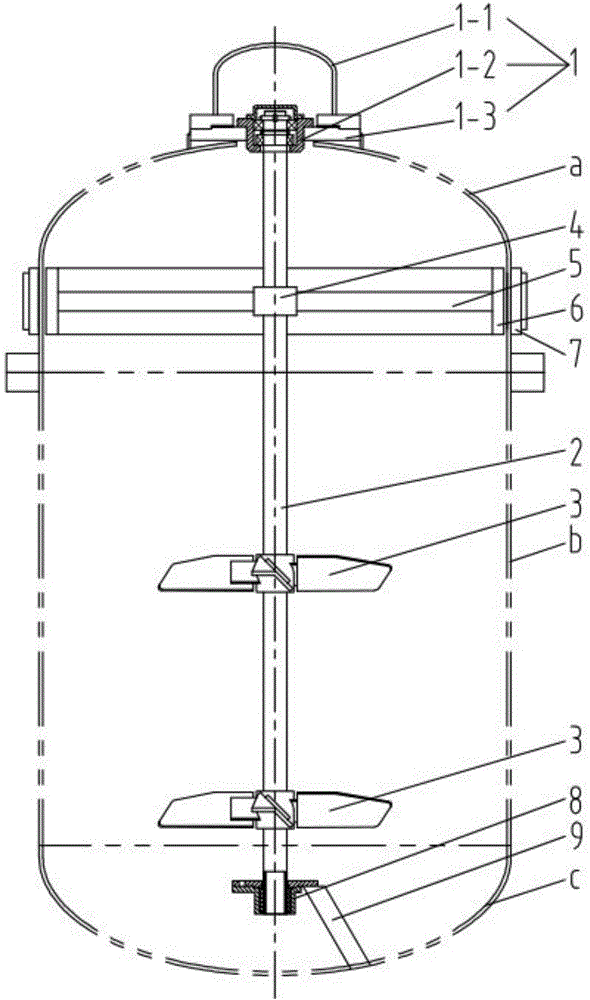

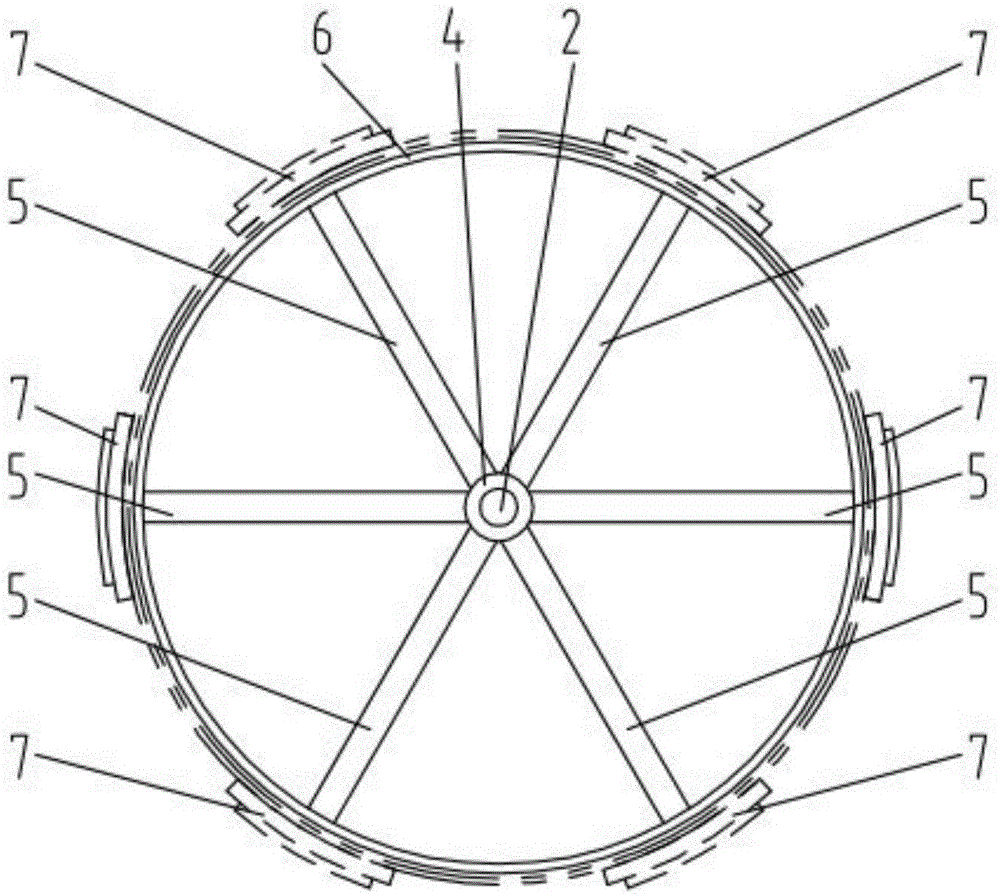

[0016] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0017] Linear motors are widely used in various industries, such as: high-speed maglev trains, three-dimensional parking garages, logistics transportation lines, elevators, ultra-high-speed motors, etc.

[0018] The main features of linear motors are:

[0019] a. Simple structure: Since the linear motor does not need an additional device to change the rotary motion into a linear motion, the structure of the system itself is greatly simplified, and the weight and volume are also greatly reduced.

[0020] b. High positioning accuracy: Where linear motion is required, the linear motor can realize direct transmission, so various positioning errors caused by inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com