Making method of Lingyun Baekho black tea

A production method and technology for black tea, applied in the direction of tea treatment before extraction, can solve the problems of low market price, loss of tea farmers, turbid soup color, etc., and achieve the effect of improving internal and external quality, mellow taste and sweetness, and red soup color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

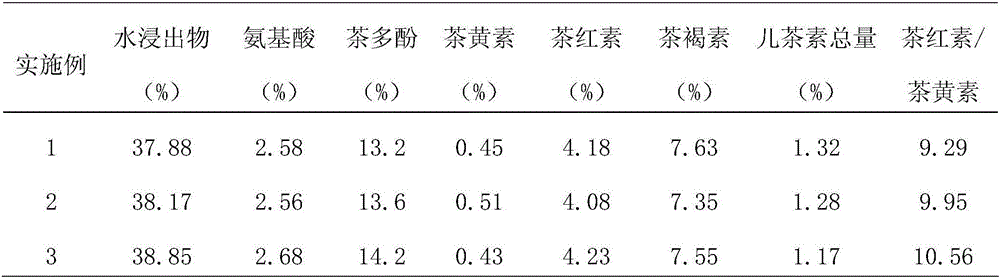

Examples

Embodiment 1

[0022] a. Picking and drying: Pick 1-2 leaves of a fresh bud of Lingyun Pekoe, spread and dry at a controlled room temperature at 22°C, the thickness of the spread is 2-5cm, flip it every 4 hours, and the spread time is 10- 12 hours;

[0023] b. Knead for 10-20 minutes;

[0024] c. Fermentation: disintegrate the tea leaves after kneading, add licorice into water 6-10 times its weight, heat to boiling, keep boiling for 3-5 minutes, filter, spray on the above-mentioned tea leaves, place in the fermentation room for fermentation, The fermentation temperature is controlled at 20-25°C, the humidity is maintained at 90-95%, and the fermentation time is 3-5 hours; the weight of the licorice is 1% of the weight of the above-mentioned tea leaves;

[0025] d. Drying: Dry the fermented tea leaves, the first drying temperature is 90-100°C, and the drying time is 10-15 minutes; cool down; then lower the drying temperature to 100°C Next, continue to dry, the drying time is 2-3 hours.

[...

Embodiment 2

[0028] a. Picking and drying: Pick 1-2 leaves of a fresh bud of Lingyun Pekoe, spread and dry at a controlled room temperature at 22°C, the thickness of the spread is 2-5cm, flip it every 4 hours, and the spread time is 10- 12 hours;

[0029] b. Knead for 10-20 minutes;

[0030] c. Fermentation: disintegrate the tea leaves after kneading, add licorice into water 6-10 times its weight, heat to boiling, keep boiling for 3-5 minutes, filter, spray on the above-mentioned tea leaves, place in the fermentation room for fermentation, The fermentation temperature is controlled at 20-25°C, the humidity is maintained at 90-95%, and the fermentation time is 3-5 hours; the weight of the licorice is 2% of the weight of the above-mentioned tea leaves;

[0031] d. Drying: Dry the fermented tea leaves, the first drying temperature is 90-100°C, and the drying time is 10-15 minutes; cool down; then lower the drying temperature to 100°C Next, continue to dry, the drying time is 2-3 hours.

[...

Embodiment 3

[0034] a. Picking and drying: Pick 1-2 leaves of a fresh bud of Lingyun Pekoe, spread and dry at a controlled room temperature at 22°C, the thickness of the spread is 2-5cm, flip it every 4 hours, and the spread time is 10- 12 hours;

[0035] b. Knead for 10-20 minutes;

[0036] c. Fermentation: disintegrate the tea leaves after kneading, add licorice into water 6-10 times its weight, heat to boiling, keep boiling for 3-5 minutes, filter, spray on the above-mentioned tea leaves, place in the fermentation room for fermentation, The fermentation temperature is controlled at 20-25°C, the humidity is maintained at 90-95%, and the fermentation time is 3-5 hours; the weight of the licorice is 1.5% of the weight of the above-mentioned tea leaves;

[0037] d. Drying: Dry the fermented tea leaves, the first drying temperature is 90-100°C, and the drying time is 10-15 minutes; cool down; then lower the drying temperature to 100°C Next, continue to dry, the drying time is 2-3 hours.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com