Intelligent high-voltage cable heating and straightening all-in-one machine and control method thereof

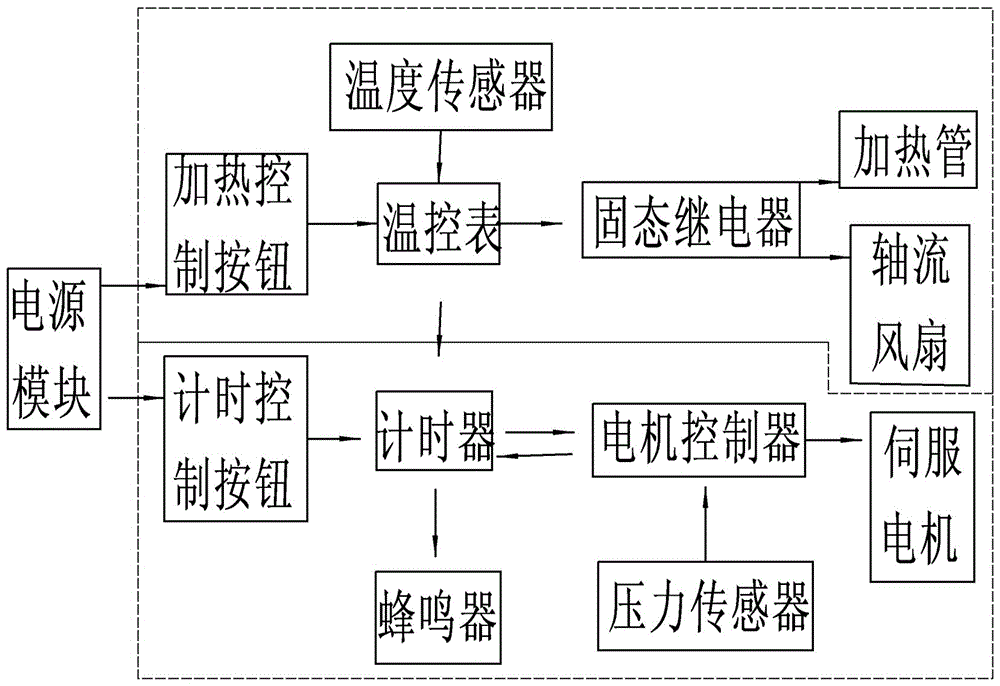

A technology for high-voltage cables and motor controllers, which is used in cable installation, cable installation devices, and equipment for connecting/terminating cables, etc. Straightness can not be guaranteed and other problems, to achieve the effect of improving the effect of heating and heat preservation, compact structure and maintaining consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] For the convenience of expressing clearly, left, right, up and down are defined by people reading the drawings normally, the direction of the drawing facing the person is the front, and the direction away from the person is the back.

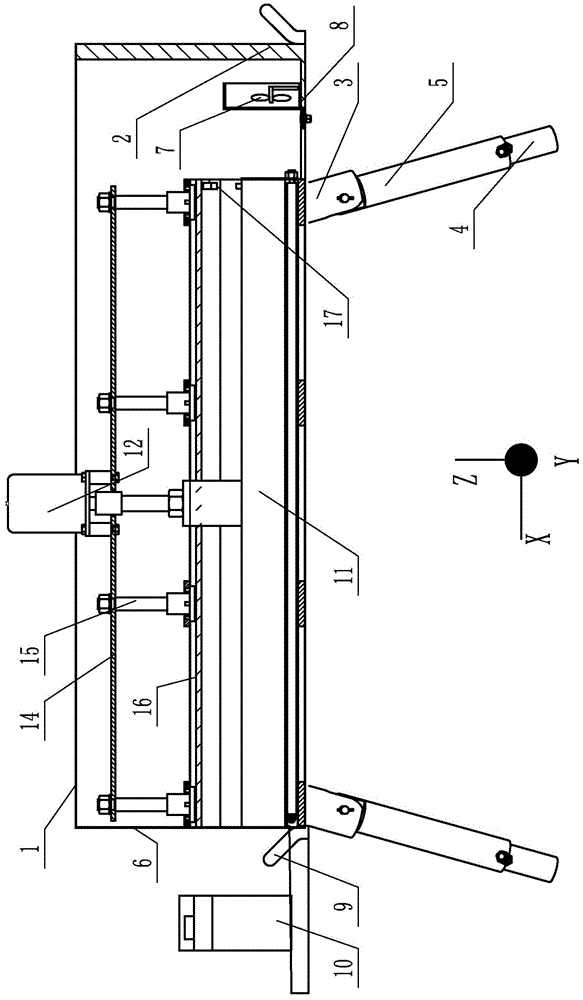

[0042] like Figure 1-5 As shown, the present invention includes a base frame 3, an outer casing 1 arranged at the upper end of the bottom frame 3, a right cover 2 arranged at the right end of the outer casing 1, a left end cover 6 arranged at the left end of the outer casing 1, and an outer casing 1 arranged at the left end of the outer casing 1. The heating tube at the lower part of the left end or the lower part of the right end, the lower fixed V-shaped clamping block 11 arranged on the upper end of the floor frame 3 along the X direction, and the clamping integrated machine 12 arranged in the outer casing 1;

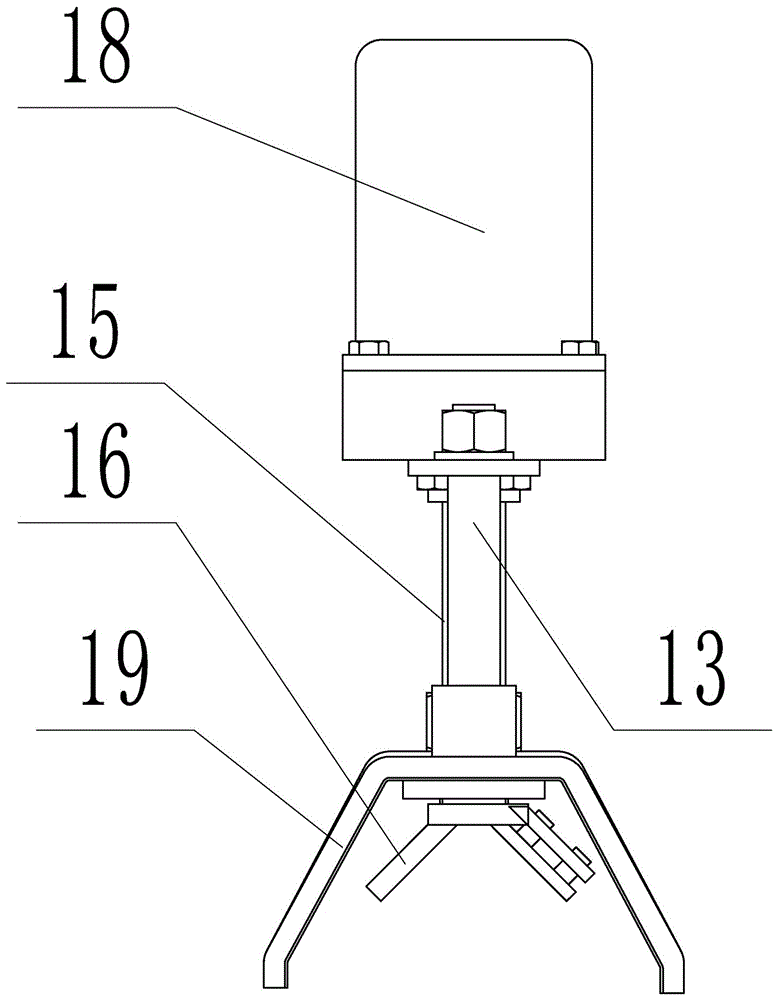

[0043] The clamping integrated machine 12 includes an arched fixing frame 19 fixedly arranged on the floor frame 3, an electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com