Air-liquid separator group for refrigerating system

A gas-liquid separator and refrigeration system technology, applied in refrigeration components, refrigeration and liquefaction, refrigerators, etc., can solve problems such as compressor liquid shock, compressor damage, unreasonable design of the gas-liquid separator group, etc., to achieve flow The effect of good distance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

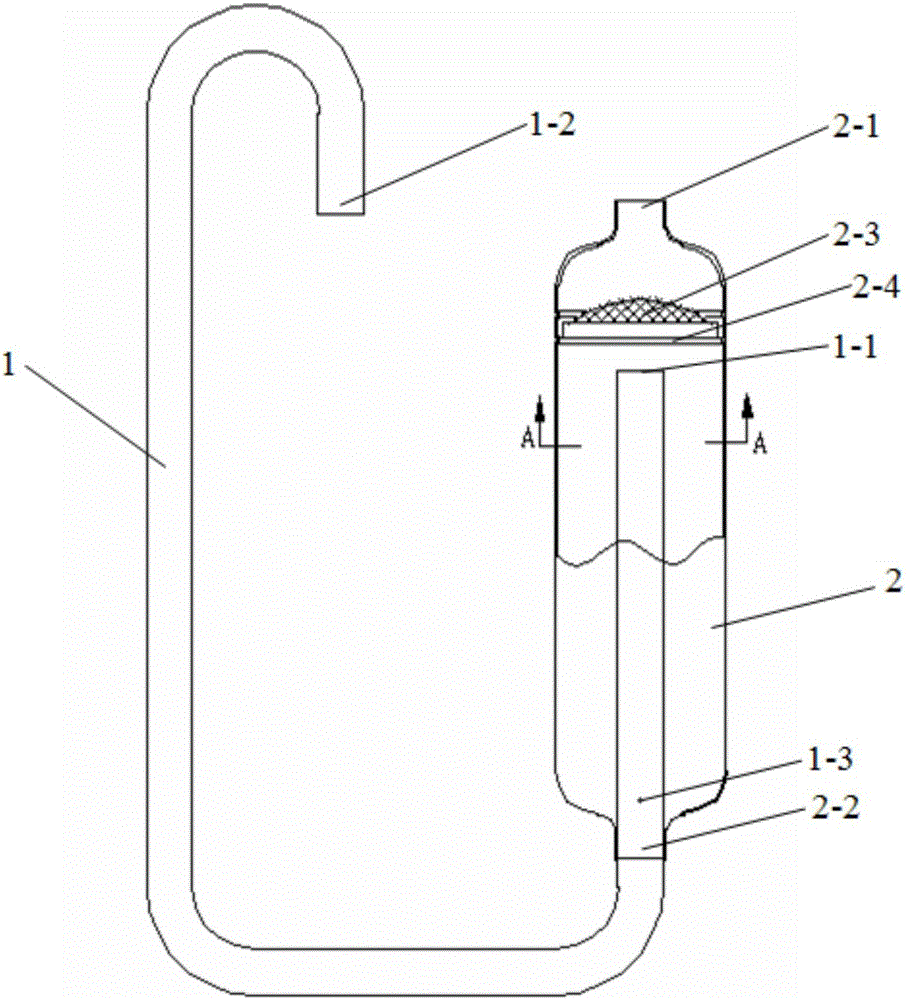

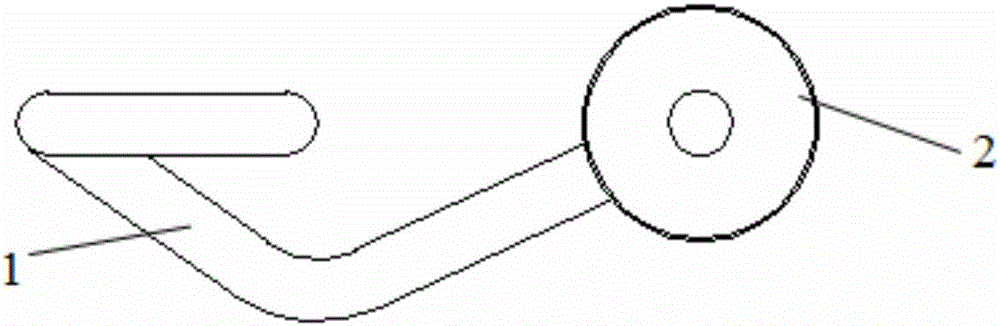

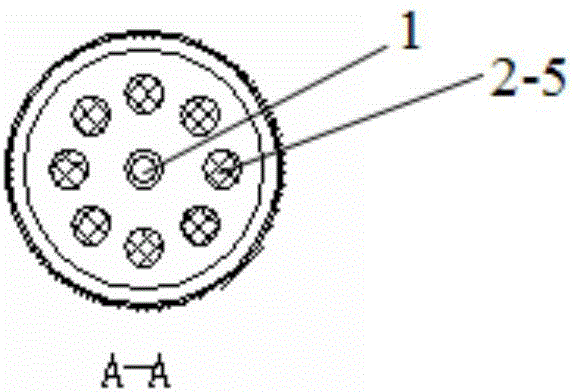

[0017] See attached Figure 1-Figure 3 As shown, a gas-liquid separator group for a refrigeration system is composed of a liquid storage tank 2 and a gas return pipe 1. The liquid storage tank 2 is a hollow cylinder with an upper port 2-1 and a lower port 2-2. , a filter screen 2-3 is provided at a distance of 50cm ± 5cm from the upper port 2-1, and a liquid separation baffle 2-4 is provided at the lower end of the filter screen 2-3; the shape of the return air pipe 1 is U-shaped circular pipe, which has an air inlet port 1-1 and an air return port 1-2, the air inlet port 1-1 is inserted into the liquid storage tank 2 and connected to the liquid separation baffle 2-4 There is a distance of 10-15mm between them, and an oil return hole 1-3 is provided on the air return pipe 1 inserted into the liquid storage tank 2 .

[0018] Preferably, the filter screen 2-3 is 60 mesh.

[0019] Preferably, the filter screen 2-3 is made of 1Cr18Ni9Ti.

[0020] Preferably, the liquid separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com