Structure of locknut and locking adjusting method for locknut

A technology for locking nuts and main nuts, applied in the directions of nuts, screws, bolts, etc., can solve the problems of complex manufacturing, structural limitations, and potential safety hazards, and achieve simple manufacturing processes, large locking torque, and high impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

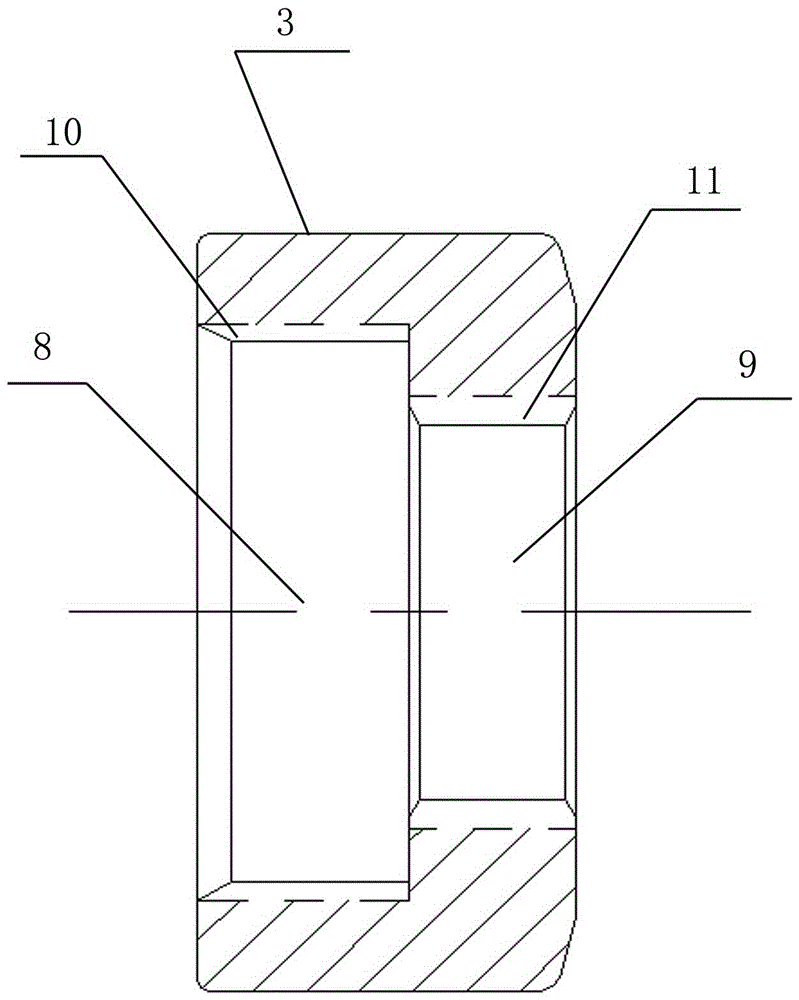

[0014] Embodiment one, in figure 1 , figure 2 with image 3 Among them, the present invention discloses a lock nut structure, including bolt 1, main nut 2 and auxiliary nut 3, the central inner hole 14 of the main body of the main nut 2 is provided with an internal thread I13, and the front section of the main nut 2 is provided with It is the nut head 4, the middle section of the main nut 2 is set as the middle threaded section 5, and the surface of the middle threaded section 5 is provided with an external thread I6, and the external thread I6 is a forward fine-pitch straight thread or a reverse fine-pitch straight thread , the external thread I6 can also be a forward taper thread or a reverse taper thread, the rear section of the main nut 2 is set as the tail adjustment section 7, the circumference of the nut head 4 is greater than the circumference of the middle screw connection section 5, and the middle screw The diameter of connecting section 5 is greater than the diam...

Embodiment 2

[0016] Embodiment two, in figure 1 , figure 2 with image 3 Among them, the present invention provides a locknut structure, which includes a bolt 1, a main nut 2 and an auxiliary nut 3, the central inner hole 14 of the main body of the main nut 2 is provided with an internal thread I13, and the front section of the main nut 2 It is set as the nut head 4, and the middle section of the main nut 2 is set as the middle screw joint section 5, and the surface of the middle screw joint section 5 is provided with an external thread I6, and the external thread I6 is a forward fine thread straight thread or a reverse thread. Fine pitch straight thread, the external thread I6 can also be a forward taper thread or a reverse taper thread, the rear section of the main nut 2 is set as the tail adjustment section 7, and the circumference of the nut head 4 is larger than the middle threaded section 5, the diameter of the middle threaded section 5 is greater than the diameter of the tail adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com