A completely decoupled two-rotation-one-shift three-degree-of-freedom parallel mechanism

A completely decoupled, degree-of-freedom technology, applied in the field of robotics, can solve problems such as difficult control, complex kinematic equations, strong motion coupling, etc., and achieve the effect of strong practicability, high structural rigidity, and simple control model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

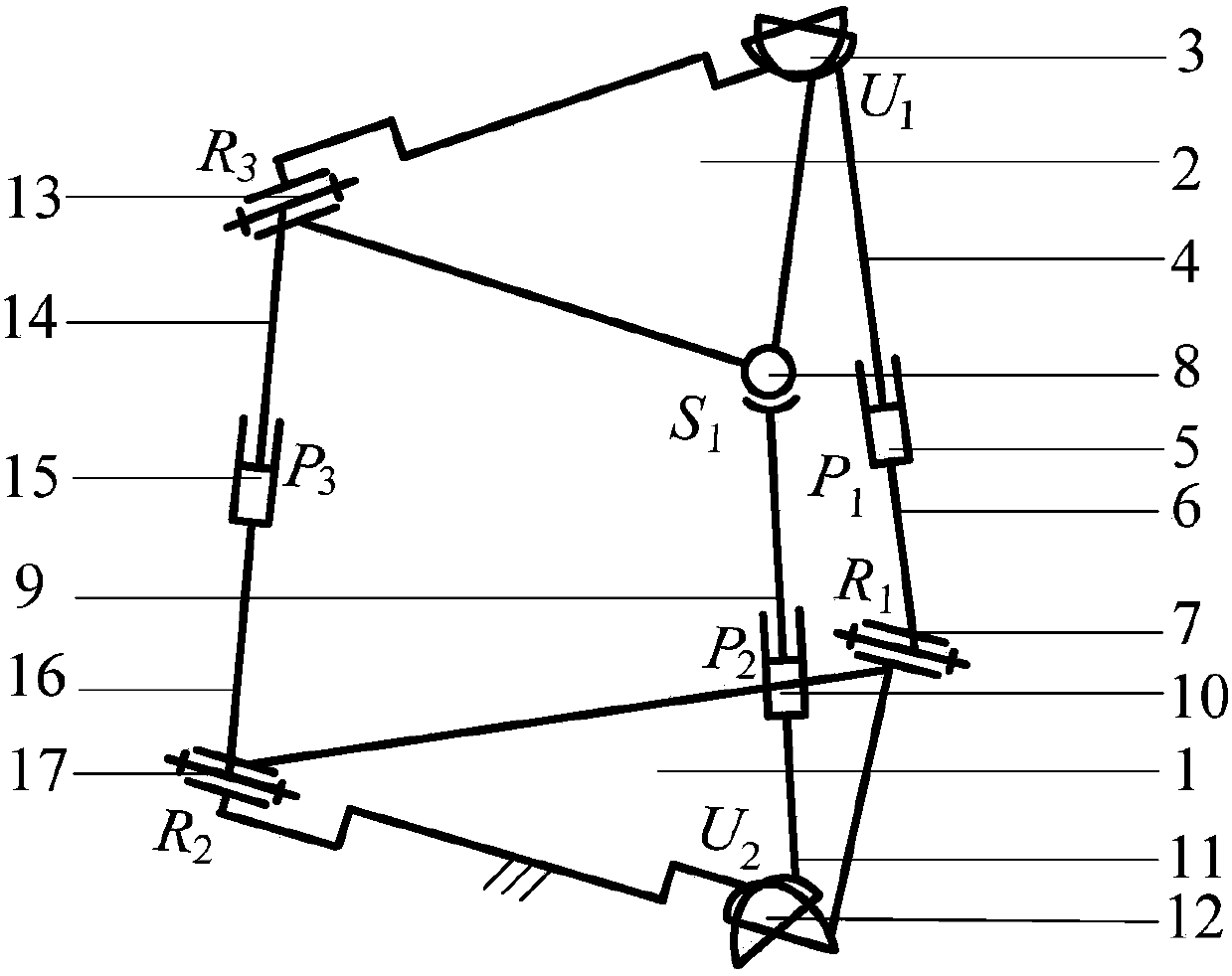

[0007] exist figure 1 In the schematic diagram of the fully decoupled two-rotation-one-shift three-degree-of-freedom parallel mechanism shown, one end of the upper link 4 of the first branch chain is connected to the moving platform 2 through the Hooke hinge 3, and the other end of the upper link is moved by moving The pair 5 is connected with one end of the lower connecting rod 6, and the other end of the lower connecting rod is connected with the fixed platform 1 through the rotating pair 7; one end of the upper connecting rod 9 of the second branch chain is connected with the moving platform through the ball pair 8, and the upper The other end of the connecting rod is connected with one end of the lower connecting rod 11 through the moving pair 10, and the other end of the lower connecting rod is connected with the fixed platform through the Hooke hinge 12; Connected with the moving platform, the other end of the upper connecting rod is connected with one end of the lower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com