Active air-cooling heat dissipation battery box for hybrid electric vehicle

A technology for hybrid vehicles and battery boxes, applied in secondary batteries, battery pack components, circuits, etc., can solve the problem that heat cannot be quickly and effectively dissipated, the temperature of the battery surface is asynchronous, and the peak heat cannot be timely. and other problems to achieve the effect of ensuring charge and discharge performance, preventing heat dissipation lag, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

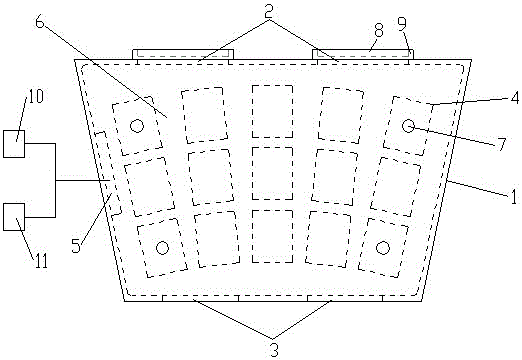

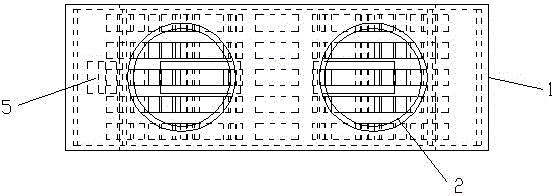

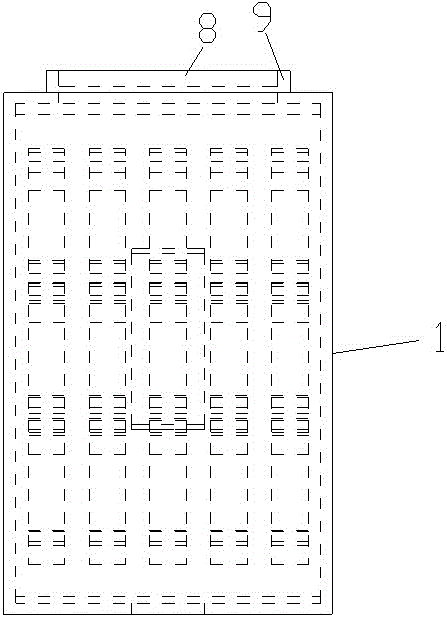

[0021] Such as figure 1 An active air-cooled heat-dissipating battery box for a hybrid electric vehicle shown includes a battery box 1. The battery box 1 has a trapezoidal structure. The top of the battery box 1 is provided with two circular air inlets 2 distributed left and right. There are two left and right rectangular air outlets 3 at the bottom, fan-shaped battery packs 4 are arranged inside, and a temperature monitoring and warning module 5 is arranged on the left side of the inside, and heat dissipation air ducts 6 are arranged between the longitudinally arranged battery packs 4, The battery pack 4 located in the eight corners of the battery box 1 is provided with temperature sensors 7, the air inlet 2 is provided with a cooling fan 8 and a ventilating, dust-proof and waterproof cotton 9; the temperature monitoring and warning module 5 is externally connected to a fan controller 10 and sound and light alarm 11.

[0022] The temperature sensor used in the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com