Paraffin wax soft curvature test system and use method thereof

A testing system and curvature technology, applied in the investigation phase/status change and other directions, can solve the problems of not meeting customer requirements, the cost of penetration instruments, etc., to achieve the effect of reducing measurement costs, practical guiding significance, and intuitive experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

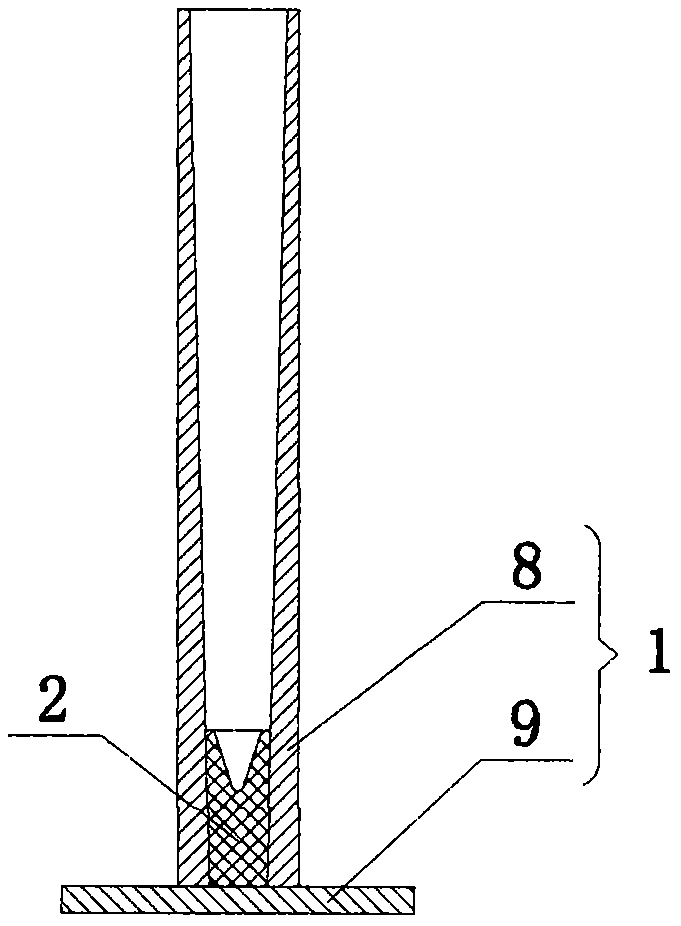

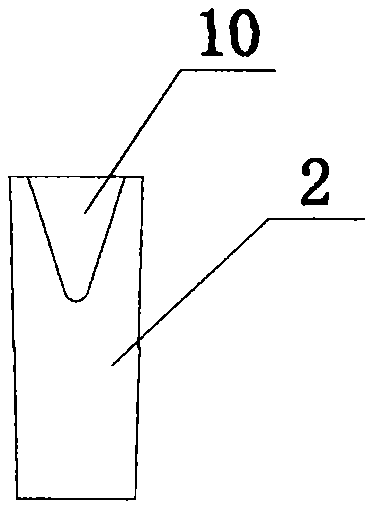

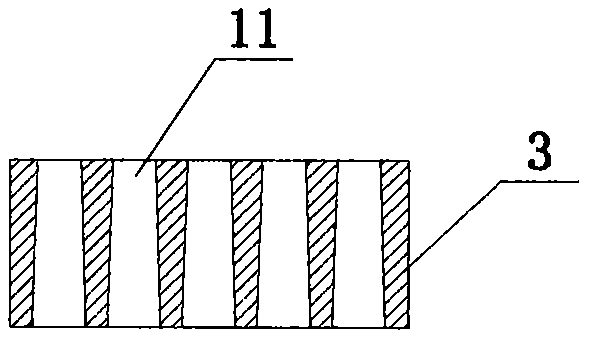

[0047] Such as figure 1 Shown, a kind of paraffin wax soft curvature testing system comprises wax strip former, wax strip holder 3 and thermostat 4, and described wax strip former comprises wax strip former main body 1 and wax strip head former 2, and wax strip The bottom of the main body of the strip former 1 is provided with a wax strip head former 2; the wax strip holder 3 includes a wax strip holder main body; the thermostat 4 includes a thermostat housing 5, a temperature control device 6 and a bracket 7, A temperature control device 6 and a bracket 7 are arranged inside the thermostat shell 5 .

[0048] Such as figure 1 As shown, the main body 1 of the wax strip forming device includes a base 9 and a wax strip forming tube 8 welded on the base 9. The inner diameter of the top of the wax strip forming tube 8 is greater than the inner diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com