Novel test system for thermal stability of phase-change material

A phase change material, thermal stability technology, applied in the investigation phase/state change and other directions, can solve the problems of low work efficiency, low heat transfer, high initial investment, etc., to achieve less space occupation, low economic cost, and operation strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the drawings and specific embodiments.

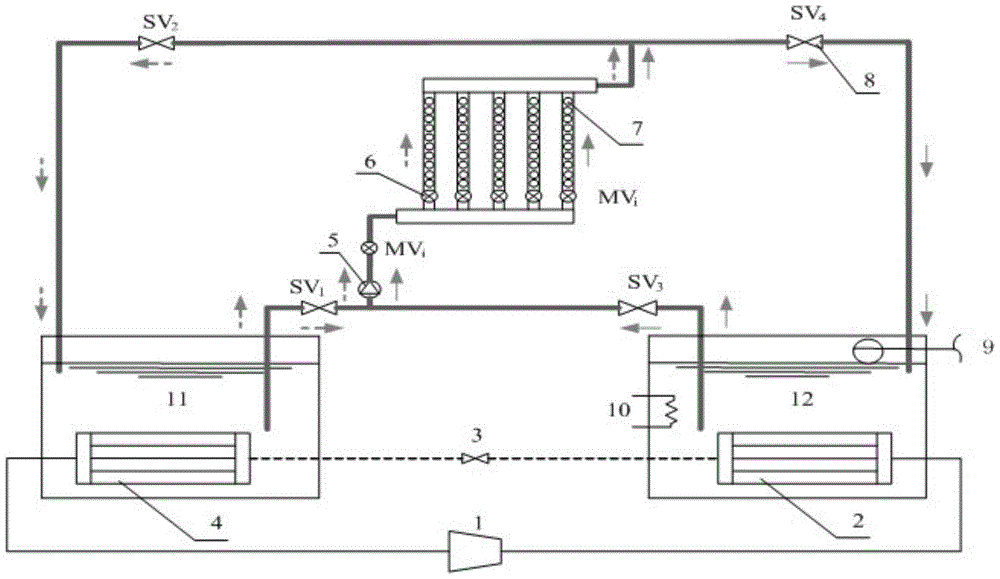

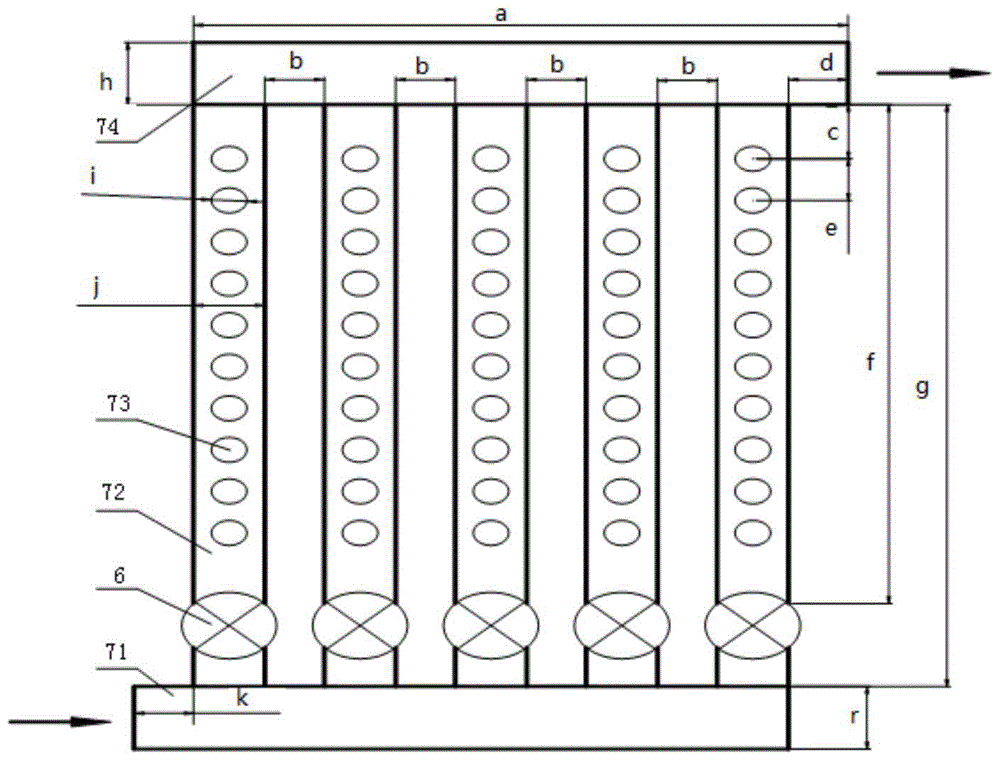

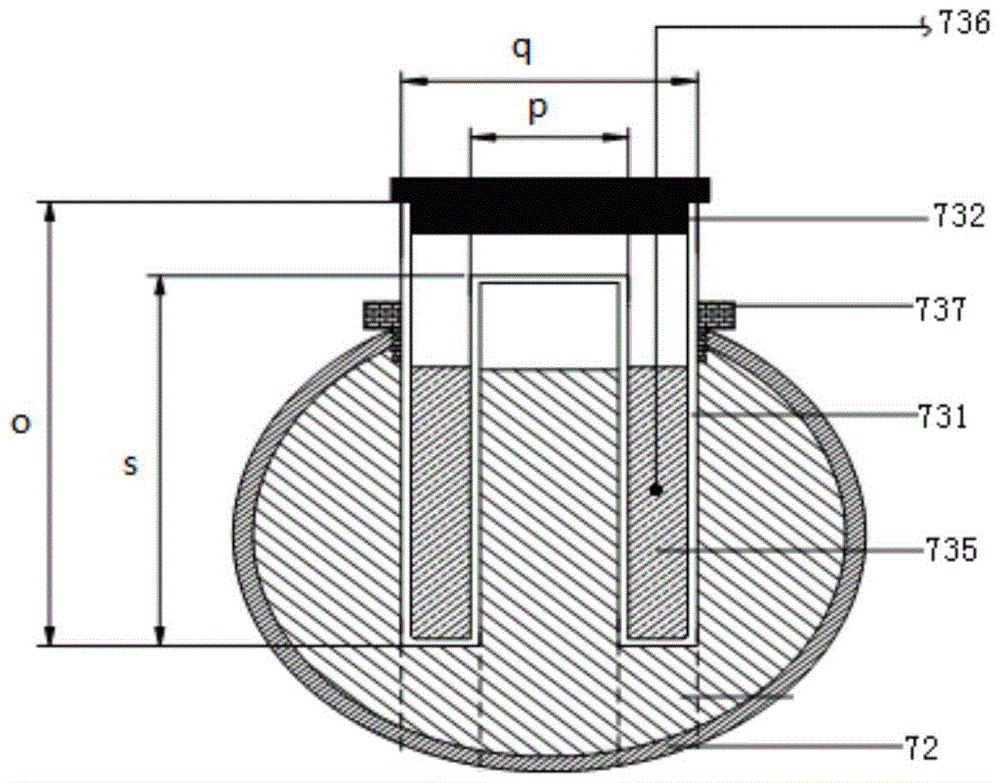

[0022] A new type of phase change material thermal stability test system, which can be used to test the thermal stability of phase change materials, such as figure 1 As shown, it includes a cold and hot water circulation supply subsystem, a quick-heating and quick-cooling sample test area 7, a mode switching automatic control subsystem, a data measurement system, and a data acquisition cycle count system.

[0023] Wherein, the cold and hot water circulation supply subsystem includes a cold water storage tank 11, a hot water storage tank 12 and a heat pump cycle module. The heat pump cycle module includes a compressor 1, a water-cooled condenser 2, an expansion valve 3, and a water-cooled The evaporator 4, the compressor 1 is connected to a water-cooled condenser 2 through a pipeline, the water-cooled condenser 2 is connected to the expansion valve 3 through a pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com