A device that is convenient for studying the cohesion phenomenon of granular mineral powder in the reduction process

A technology of mineral powder and particles, which is applied in the field of heating and observation devices, can solve the problems of real-time observation or less online research, and achieve the effect of strengthening air tightness and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

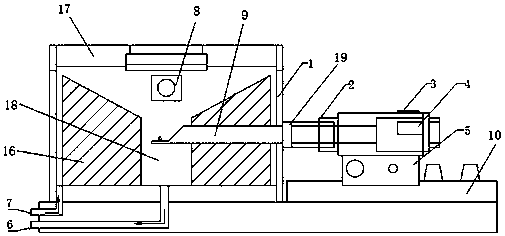

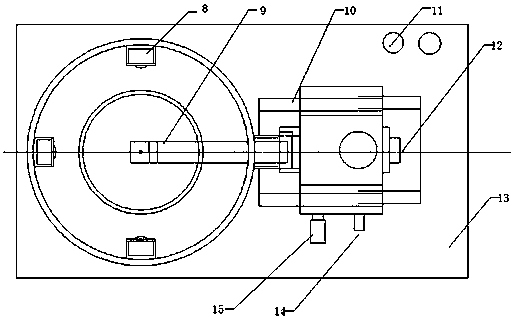

[0024] see figure 1 and figure 2 , the present invention is convenient to study the device of granular ore powder bonding phenomenon in the reducing process, comprises (stainless steel) base 13, and reduction reaction furnace is installed on base 13, and reduction reaction furnace consists of furnace body 16, is positioned at outside furnace body (stainless steel) ) furnace shell 1 and furnace cover 17, an annular interlayer is formed between the furnace body 16 and the furnace shell 1, and the annular interlayer communicates with the reaction chamber 18 in the furnace body; the furnace shell or the base is provided with an air inlet that directly communicates with the interlayer 7, the base 13 is provided with the gas outlet 6 facing the center of the reaction chamber of the furnace body; the furnace cover 17 is arranged on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com