Vertical assembly device for ultra-large centrifugal compressor impeller fixed and rotatable on one side

A technology for centrifugal compressors and assembly devices, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, non-variable pumps, etc., and can solve problems such as difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

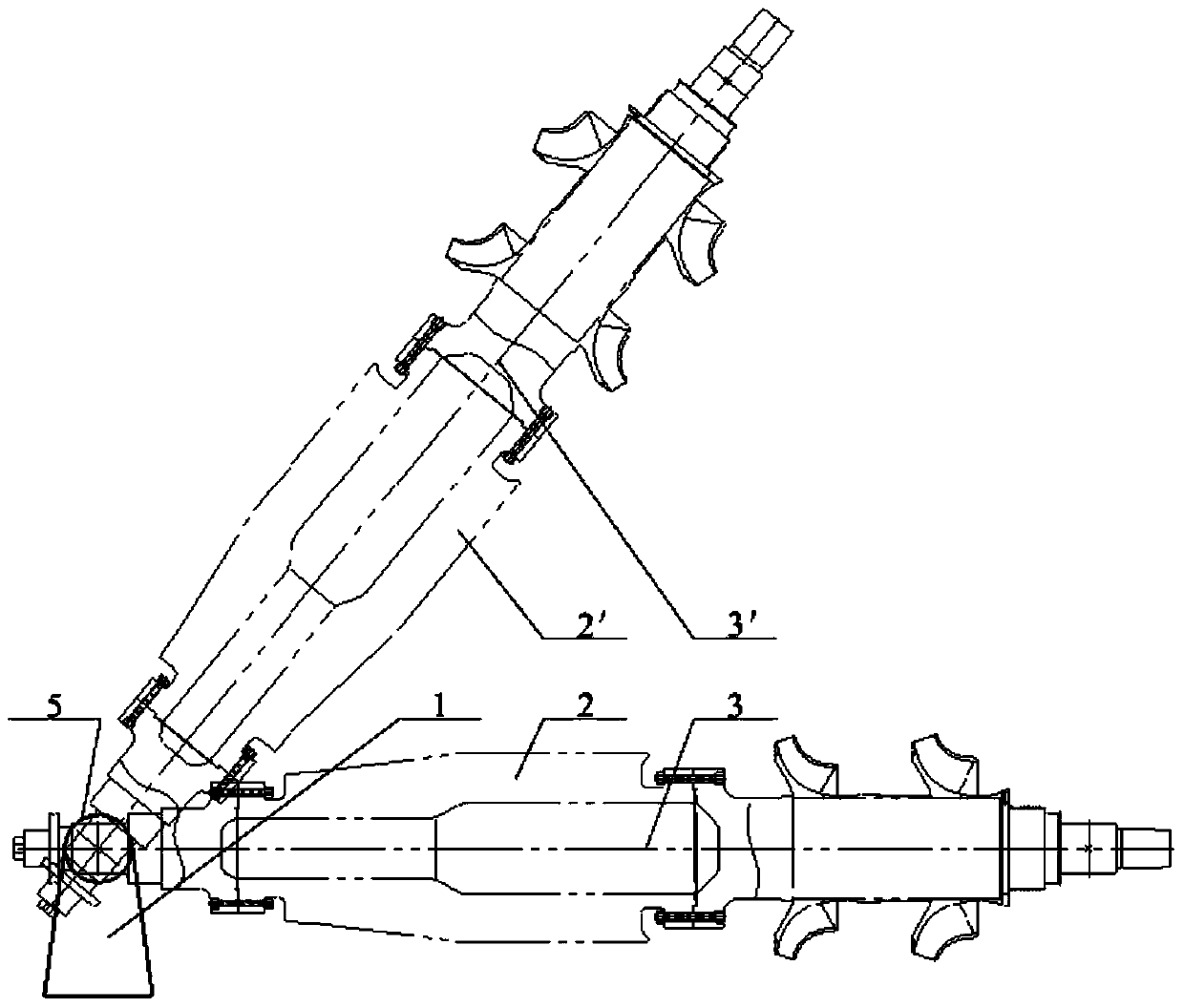

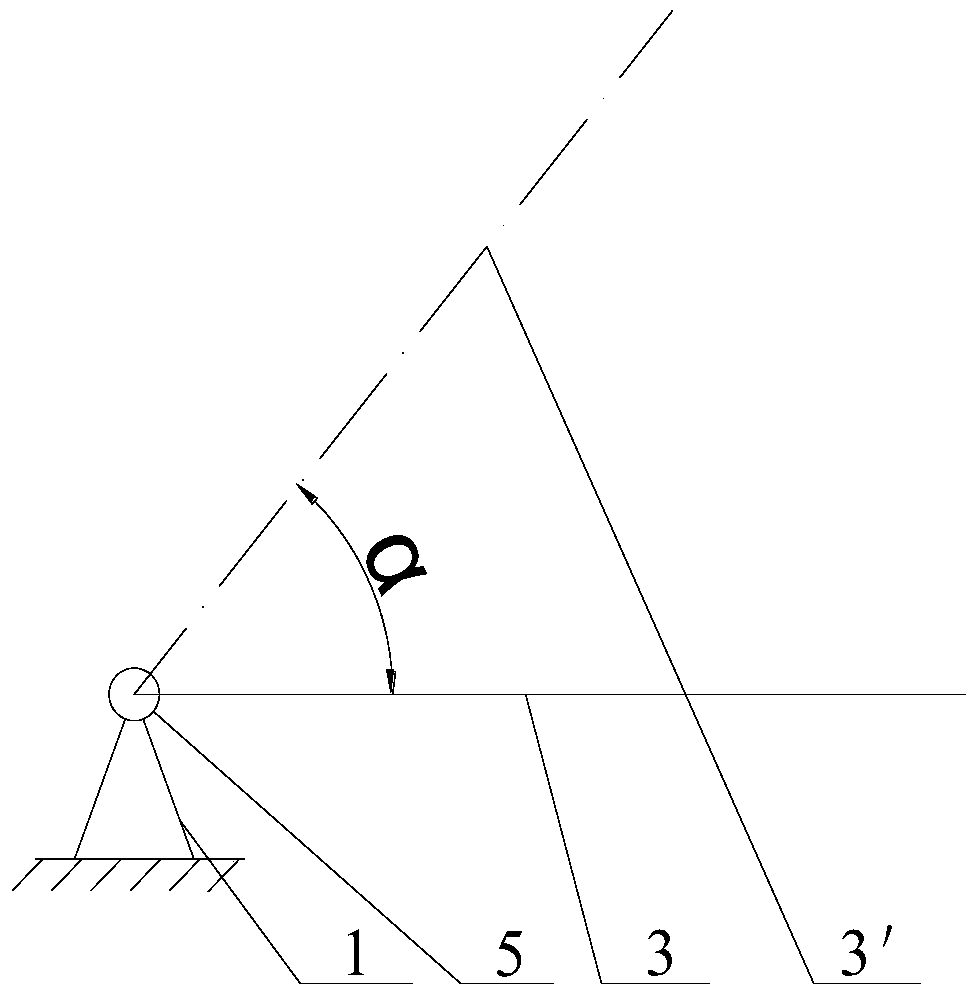

[0028] See attached Figure 1~4 , the one-side fixed and rotatable super large centrifugal compressor impeller vertical assembly device provided by the present invention includes a stator 1 and a rotating shaft 5, the rotating shaft 5 is connected to the stator 1, and the large centrifugal impeller rotor main shaft 2 can rotate with the rotating shaft 5 as the center of rotation, This enables the rotor main shaft 2 of the large centrifugal impeller to gradually change from the angle between the axis and the horizontal plane of 0° to the angle between the axis and the horizontal plane of 90°.

[0029] The one-side fixed and rotatable super large centrifugal compressor impeller vertical assembly device provided by the present invention includes a stator 1 and a rotating shaft 5, the rotating shaft 5 is connected to the stator 1, and the large centrifugal impeller rotor main shaft 2 can rotate around the rotating shaft 5, The large centrifugal impeller rotor main shaft 2 can grad...

Embodiment 2

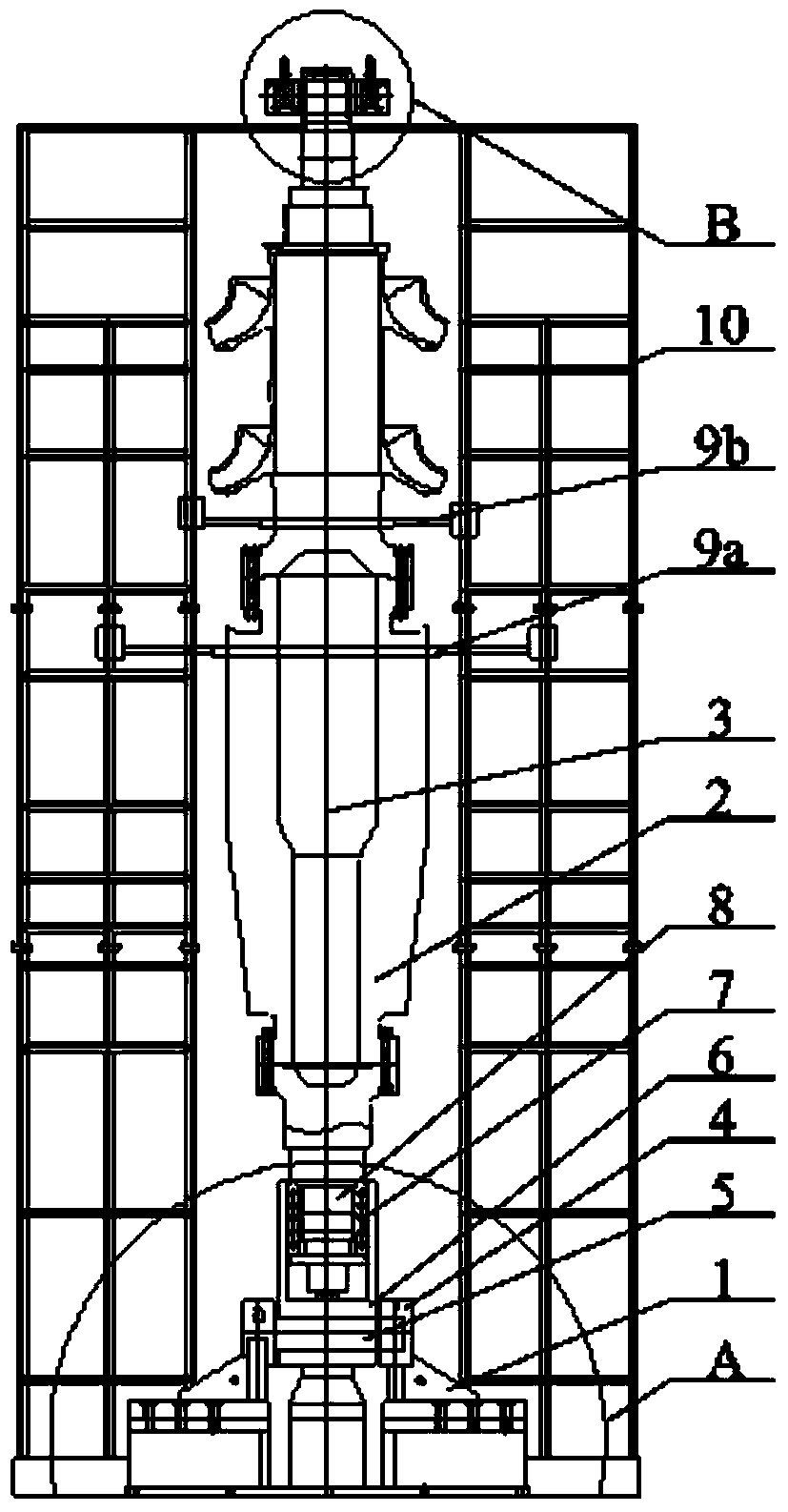

[0066] Different from the vertical assembly device for super-large centrifugal compressor impeller fixed and rotatable on one side provided in Embodiment 1 of the present invention, the vertical assembly device for super-large centrifugal compressor impeller fixed and rotatable on one side provided in Embodiment 2 of the present invention Among them, the large centrifugal impeller rotor main shaft 2 is fixedly connected to the rotating shaft 5, and the rotating shaft 5 and the stator 1 form a rotating pair.

[0067] Specifically, the stator 1 includes a base, a pair of connecting ears 4, and the pair of connecting ears 4 are respectively fixedly connected to both ends of the base, the bottom end 8 of the rotor main shaft 2 of the large centrifugal impeller is fixedly connected to the shaft sleeve 6, and the rotating shaft 5 is fixedly connected to the The axle sleeve 6, the rotating shaft 5 and the connecting ear 4 form a revolving pair.

Embodiment 3

[0069] Improvements are made on the basis of the one-sided fixed and rotatable ultra-large centrifugal compressor impeller vertical assembly device provided in Embodiment 1 or Embodiment 2 of the present invention, and the unilaterally fixed and rotatable ultra-large In the centrifugal compressor impeller vertical assembly device, the lengths of several connecting rods 11 can be adjusted. In this embodiment, the number of connecting rods 11 is 4, which are respectively connected to four points of the central sleeve. By adjusting the lengths of the 4 connecting rods 11, the axis of the large centrifugal impeller rotor main shaft 2 can be ensured. Exactly 90° angle with the horizontal plane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com