Liquid cement additive for reducing content of water-soluble Cr<6+> in cement

A cement additive and water-soluble technology, applied in the field of liquid cement additives, can solve the problems of steel bar corrosion, limited effect, easy layering and segregation, etc., and achieve the effect of small dosage, small impact and reasonable price

Inactive Publication Date: 2016-09-07

张伟

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For the way of using reducing agent, the current domestic and foreign patents and data show that the use of reducing agents such as ferrous sulfate heptahydrate and stannous chloride, stannous sulfate, zinc sulfate, zinc chloride and manganese sulfate has a good effect on eliminating Cr 6+ capacity, but the dosage of ferrous sulfate heptahydrate alone will be relatively high, generally 0.2%-0.4% in cement, while stannous chloride, stannous sulfate and manganese sulfate are limited in market acceptance due to their high prices. However, products such as zinc sulfate a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

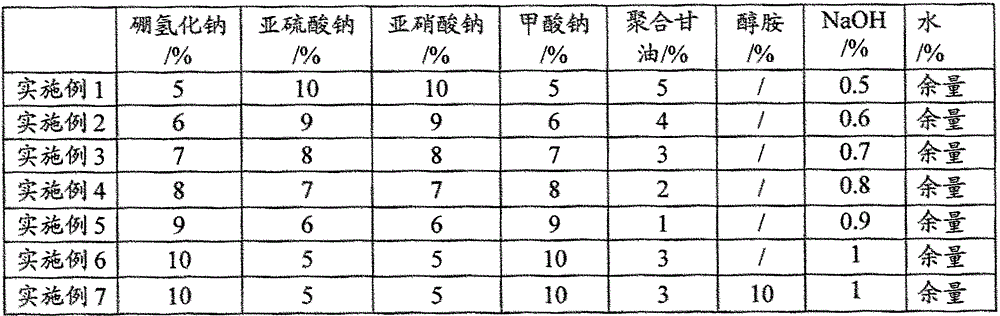

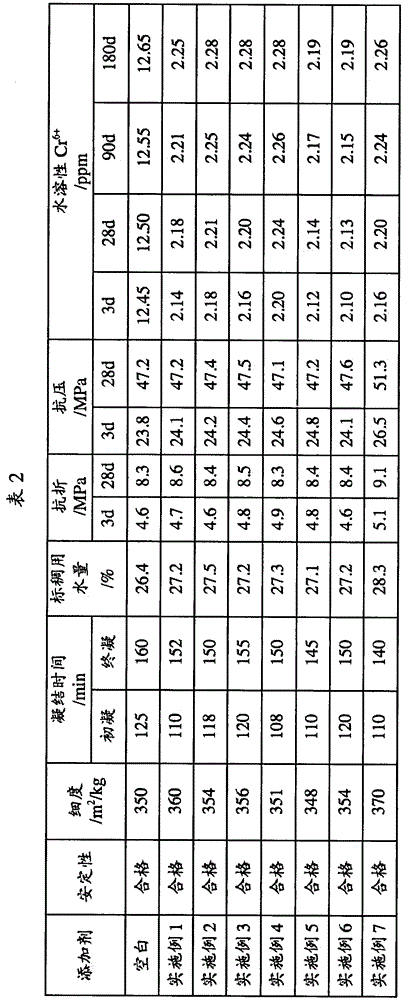

The invention provides a liquid cement additive for reducing the content of water-soluble Cr<6+> in cement. The liquid cement additive has good Cr<6+> elimination ability, and also has the advantages of reasonable price, small mixing amount, and small influences on the performances of cement. The liquid cement additive comprises, by mass, 5-10% of sodium borohydride, 5-10% of sodium sulfite, 5-10% of sodium nitrite, 5-10% of sodium formate, 1-5% of polyglycerol, 0-15% of alcohol amine, 0.5-1% of NaOH, and the balance of water, wherein the alcohol amine is at least one of triethanolamine, triisopropanolamine, diethanol isopropanolamine and methyldiethanolamine, and the pH value of the liquid cement additive is 10-14. The liquid cement additive has good Cr<6+> elimination ability, and has the advantages of reasonable price, small mixing amount, and small influences on the performances (such as water requirement of normal consistency and intensity) of cement.

Description

Technical field [0001] The invention relates to a method for reducing the water-soluble Cr of cement 6+ The content of liquid cement additives belongs to the field of building materials. Background technique [0002] Cement is the basic raw material used in industrial and civil construction concrete. After mixing with water, the cement contains water-soluble Cr 6+ It will dissolve quickly. At this time, use freshly mixed cement paste, mortar or concrete in the plastic stage, and bricklayers and concrete workers will be exposed to the soluble Cr in the cement for a long time. 6+ If reasonable labor protection measures are not adopted, sensitive people will cause skin allergies, so that incurable cement allergic contact eczema is formed, which usually manifests as pain, ulceration, and even loss of labor ability in severe cases. Water-soluble Cr in cement 6+ The sources are: 1) Cement mixed materials, such as chromium-containing industrial waste slag, which is currently water-solubl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B24/32

CPCC04B40/0039C04B22/0013C04B22/142C04B22/085C04B24/04C04B24/32C04B24/122C04B22/062

Inventor 张伟

Owner 张伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com