An automatic weighing and placing machine

A material feeding and weighing technology, applied in the field of automatic weighing and feeding machine, can solve the problems of low batching accuracy, high production cost, poor working environment, etc., and achieve extremely high work efficiency, high production accuracy and good product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

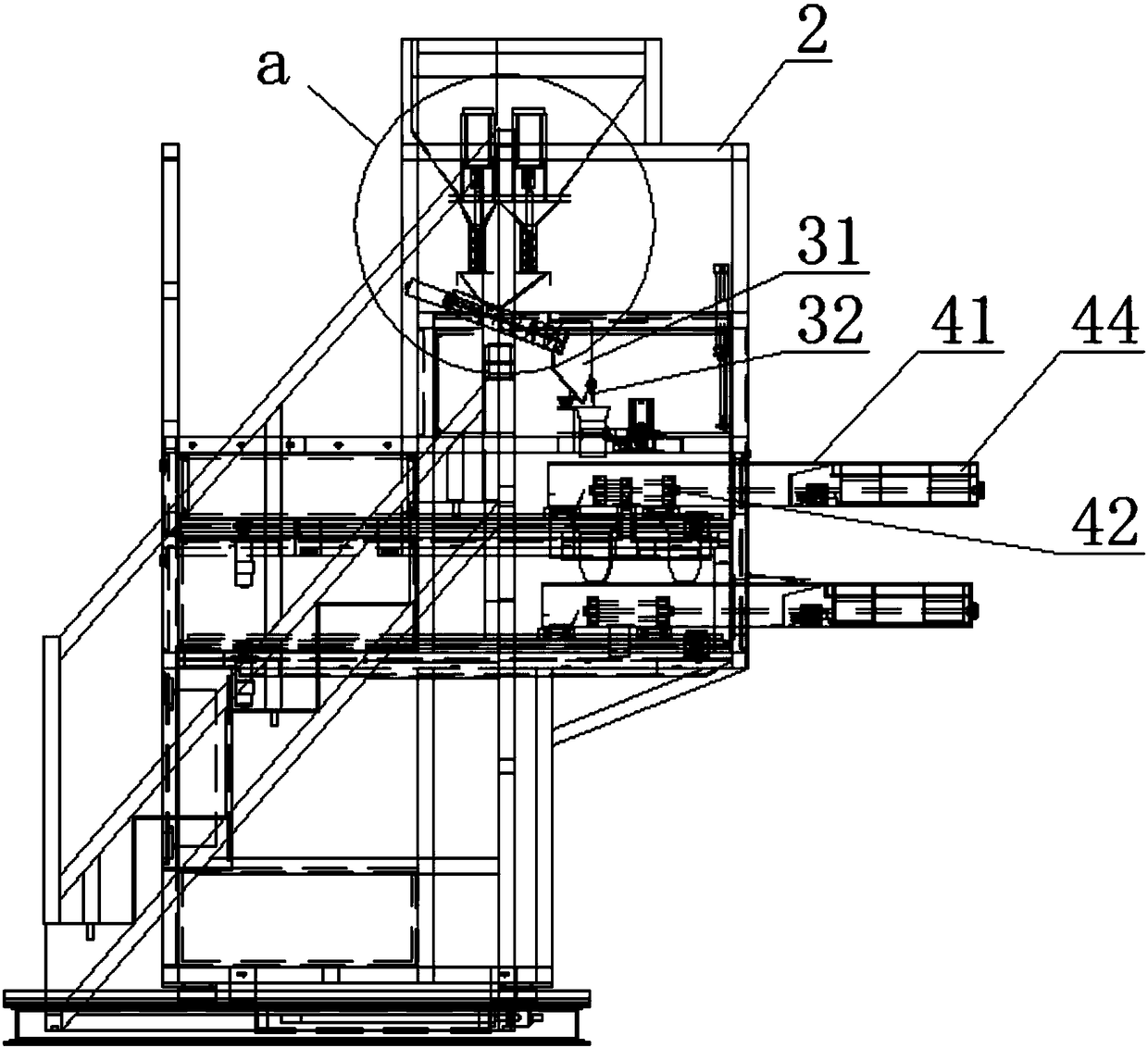

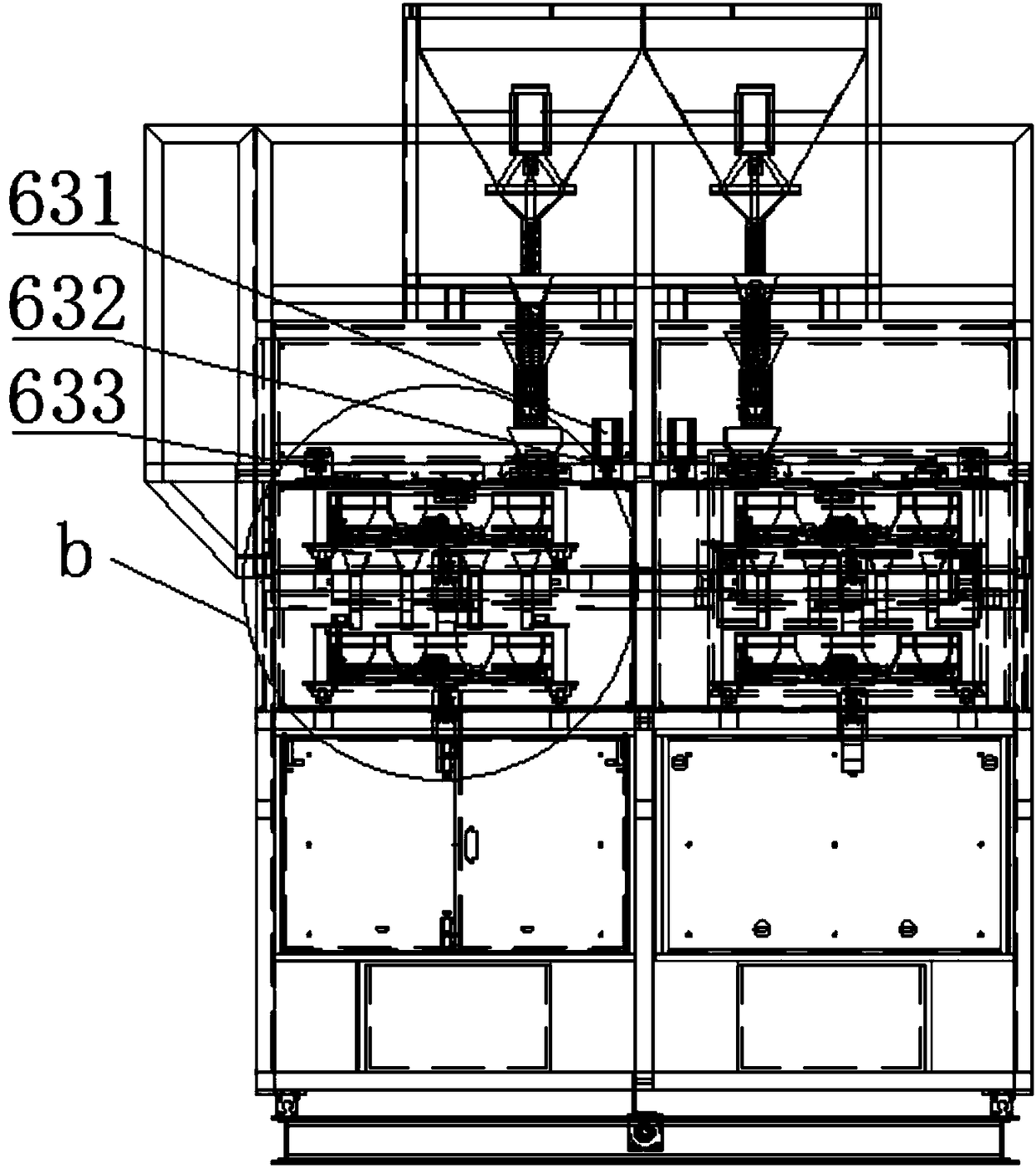

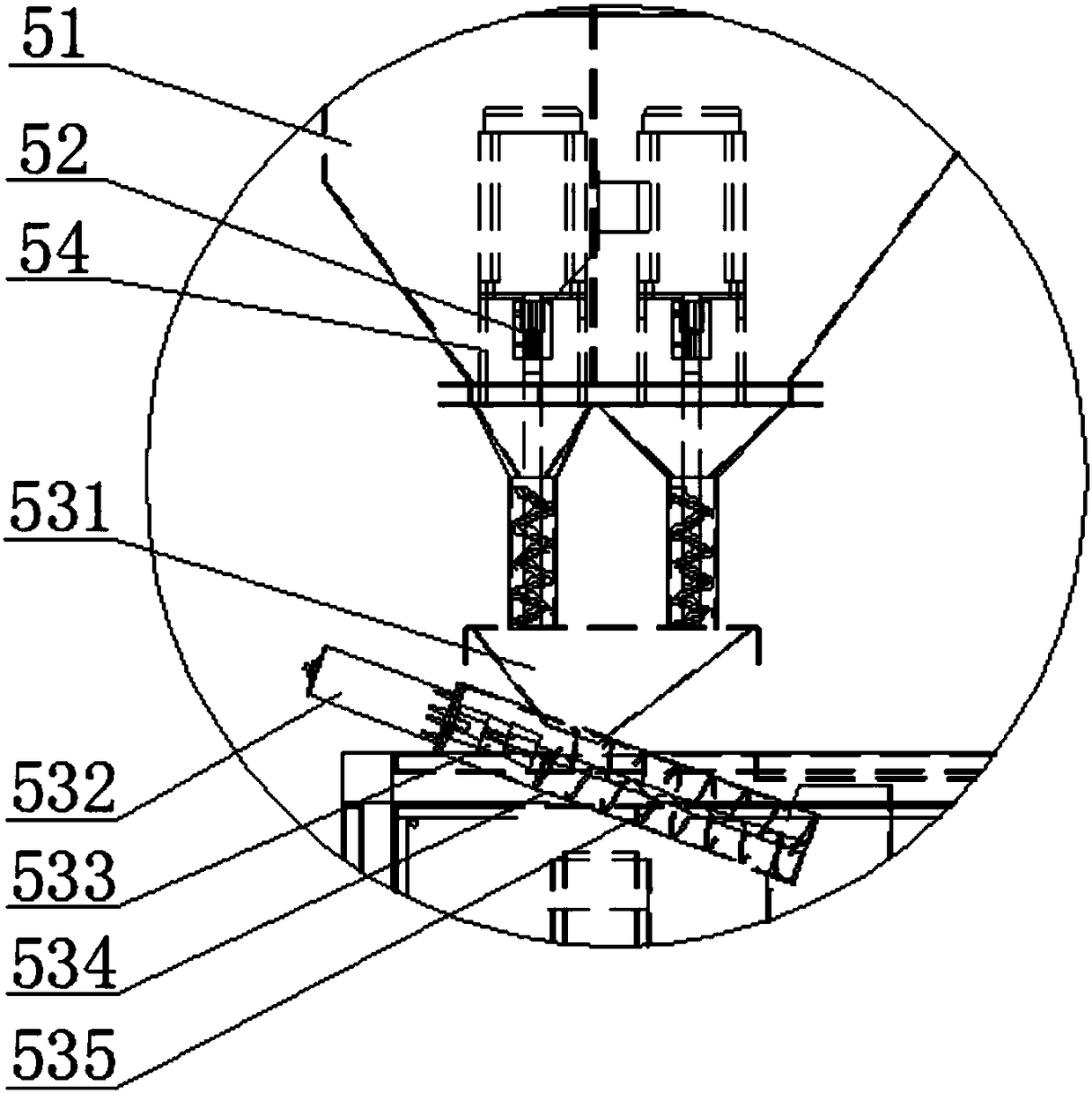

[0024] refer to figure 1 , figure 2 , image 3 and Figure 4 , an automatic weighing material placement machine, comprising a control system, a frame 2, a weighing device and a multi-layer material placement device, the weighing device includes a weighing hopper 31, a discharge door 32 and a load cell fixedly connected thereto, The bottom of the weighing sensor is fixed on the frame 2 by bolts; the multi-layer material placement device includes a material storage tank 41 and a storage tank driving device 42 that drives the storage tank 41 to move in the front and rear direction, and the material storage tank 41 passes through the bottom of the load cell. The installed slider 45 moves along the slide rail 43 erected on the frame under the drive of the trough driving device 42, and the trough 41 is provided with at least one material chamber 44; it also includes several parallel arranged spiral The storage and feeding device and the mobile distributing device, the spiral sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com