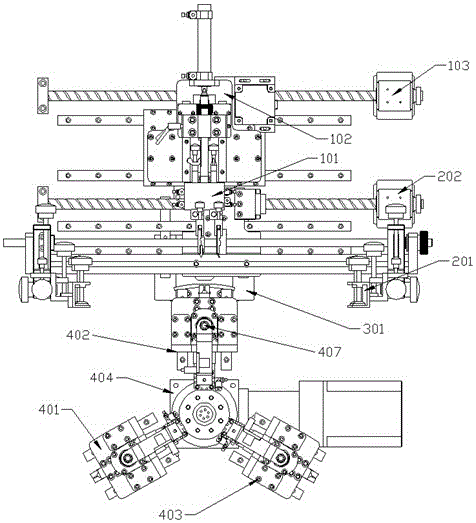

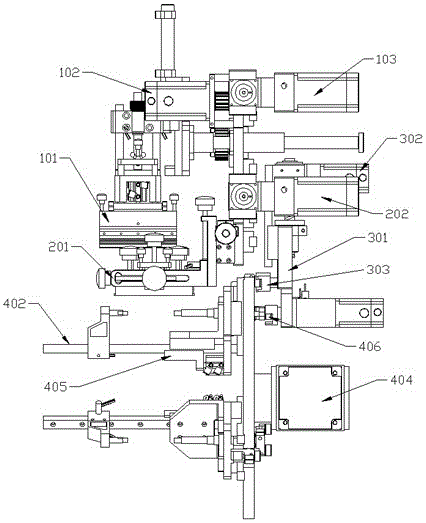

A multi-station automatic screen printing machine

A screen printing machine, fully automatic technology, applied in the direction of screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of low production efficiency, low efficiency, affecting speed, etc., to speed up the screen printing process, accurate positioning, Reduce the effect of the action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

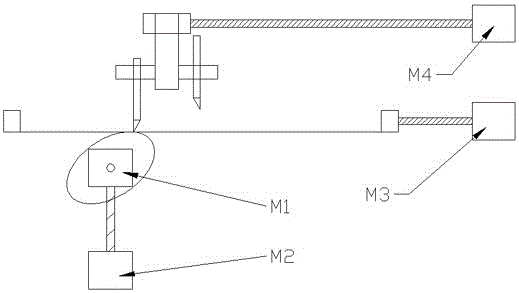

[0044] reference Figure 7 , Round bottle screen printing: The loading position manipulator clamps the workpiece 5 to be screen printed from the loading position to the printing position, the touch firmware of the manipulator is embedded in the touch floating switch of the floating assembly, and the floating assembly carries the waiting The screen printing workpiece rises to the screen frame position of the screen frame system 2, the scraper system scraper 1 is pressed down, the screen frame system 2 is activated, and the rotating shaft 4 starts synchronously, and the scraper 1 squeezes the ink through the screen onto the product 5 to form patterns and text , The floating system is lowered and reset, and the entire screen printing of the round bottle is completed.

Embodiment example 2

[0046] reference Figure 8 , Oval bottle screen printing: The loading position manipulator clamps the workpiece 5 to be screen printed from the loading position to the printing position, the touch firmware of the manipulator is embedded in the touch floating switch of the floating assembly, and the floating assembly carries the waiting The screen-printed workpiece 5 rises to the screen frame position of the screen frame system 2, and the rotating shaft 4 rotates the workpiece to the starting point, the scraper 1 presses down, the screen frame system 2 starts, and the rotating shaft 4 starts synchronously. During the screen printing process, the floating axis moves up and down Floating, keeping the surface of the workpiece to be screen-printed at a certain distance from the screen, while the scraper 1 swings around to keep the tip of the scraper 1 in contact with the highest point of the product to be screened, the scraper squeezes the ink through the screen onto the product to fo...

Embodiment example 3

[0048] Square bottle screen printing: The loading position manipulator clamps the workpiece to be screen printed from the loading position to the printing position, the touch firmware of the manipulator is embedded in the touch floating switch of the floating assembly, and the floating assembly carries the workpiece to be screen printed. Ascend to the screen frame position of the screen frame system, the scraper is pressed down, and the horizontal scraping axis motor starts to complete the single-sided screen printing. The floating shaft moves up and down once, and the rotating shaft rotates 180° at the same time to complete the square bottle turning action. The screen frame system moves one screen printing pattern to the right, the scraper presses down again, and the horizontal scraping shaft motor starts to complete the second screen printing. The same principle can complete the multi-faceted silk screen printing of the square bottle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com