Fully automatic multicolor and multi-station complex cambered digital ink-jet silk printing all-in-one machine

A digital inkjet and complex curved surface technology, which is applied to printing machines, rotary printing machines, general parts of printing machinery, etc., can solve the problems of slow printing speed, manual work, unstable quality of digital inkjet silk screen printing, etc., and achieve convenient bottle replacement , high efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

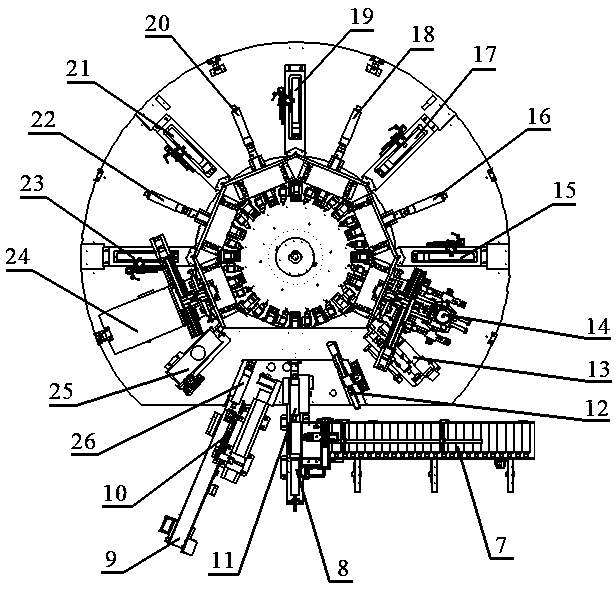

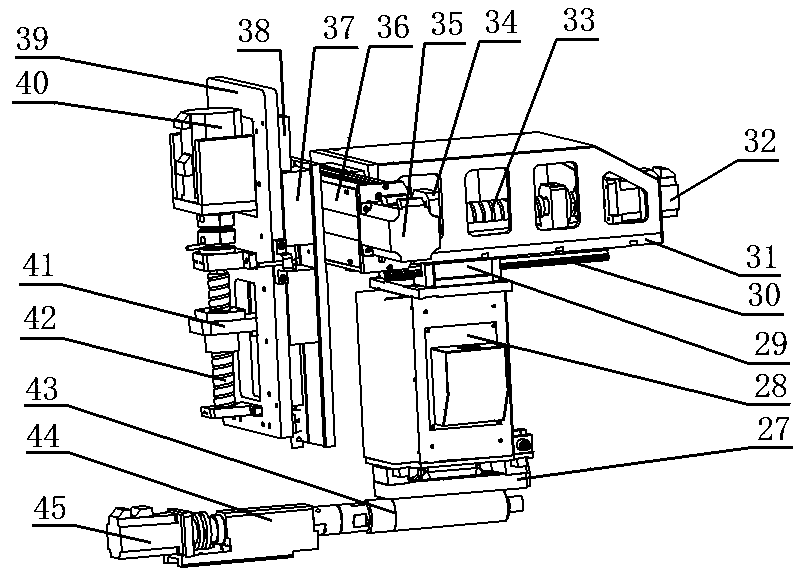

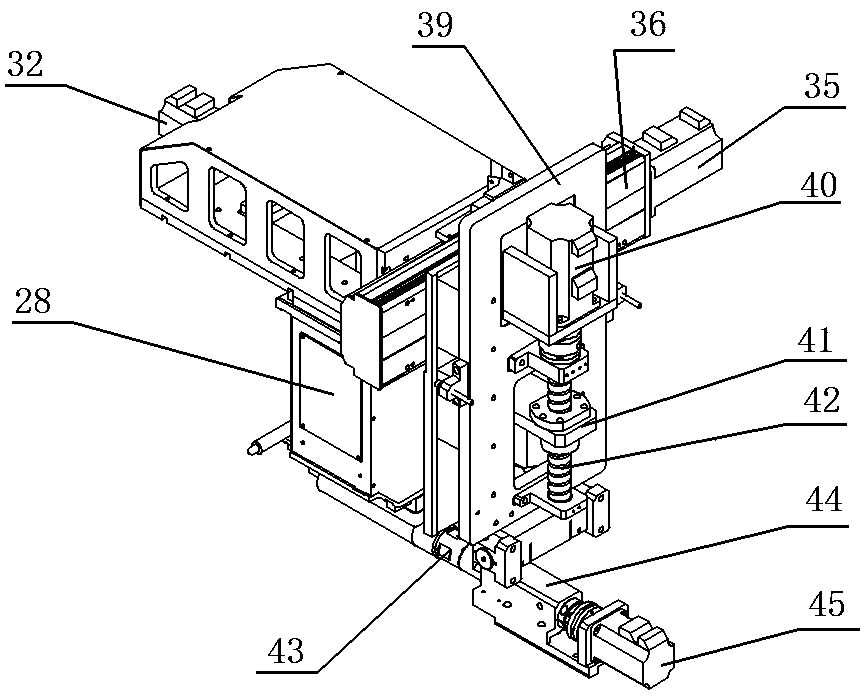

[0047] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7, Oval inkjet screen printing: a fully automatic multi-color multi-station complex curved surface digital inkjet screen printing all-in-one machine. The machine starts running at the same time, and the operator puts the oval product on the feeding conveyor belt 7, and the feeding conveyor belt 7 transports the oval product to the clamping position of the feeding manipulator 8, and the feeding manipulator 8 pushes the oval product close to the feeding machine. On the top of the jig 43 at position 11, the feeding manipulator 8 continues to push the oval product until the oval product is pushed into the bottom of the jig 43, and then the programmable controller runs and starts to control the pneumatic control valve of the jig 43 to open. Start to pump out the air in the elliptical product, and after reaching the vacuum state, the elliptical product is firmly fixed on the jig 43, ...

Embodiment example 2

[0051] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6, Inkjet screen printing for special-shaped products: a fully automatic multi-color multi-station complex curved surface digital inkjet screen printing all-in-one machine. The machine starts running at the same time, the operator puts the special-shaped product on the feeding conveyor belt 7, and the feeding conveyor belt 7 transports the special-shaped product to the clamping position of the feeding manipulator 8, and the feeding manipulator 8 pushes the special-shaped product close to the feeding position 11 At the top of the jig 43, the feeding manipulator 8 continues to push the special-shaped product until the special-shaped product is pushed into the bottom of the jig 43, and then the programmable controller runs and starts to control the pneumatic control valve of the jig 43 to open, and starts to draw out the special-shaped product. After reaching the vacuum state, the special-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com