Full-servo control monochromatic multifunctional gold stamping machine

A servo-controlled, multi-functional technology, applied in the direction of printing machines, rotary printing machines, general parts of printing machinery, etc., can solve problems such as unstable bronzing quality and slow bronzing speed, and achieve good bronzing effect, stable operation, and servo transmission Control Fast Smooth and Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

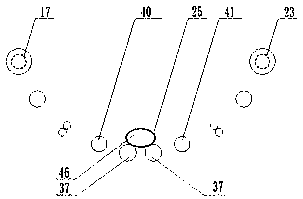

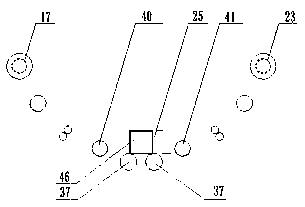

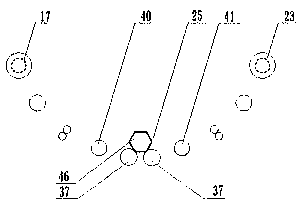

[0051] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 11 , the action sequence of quadrilateral product hot stamping is: first the operator opens the control panel, starts the first servo motor 1 and the sixth servo motor 38 of the loading and unloading conveying mechanical system, puts the quadrangular product 46 on the feeding conveyor belt 47, and the feeding and conveying The belt 47 transports the quadrilateral product 46 to the position below the gripper of the feeding manipulator 16, and the gripper of the feeding manipulator 16 grips the quadrilateral product 46. Clamp the rotating base 30 to support the bottom of the quadrilateral product 46, while the third cylinder 22 on the first turntable 18 starts to act, pushing the top block installed on the third cylinder 22 to move forward to withstand the top of the quadrilateral product 46 until After cooperating with the first clamping r...

Embodiment example 2

[0063] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 12, the action sequence of hexagonal product bronzing is: first the operator opens the control panel, starts the first servo motor 1 and the sixth servo motor 38 of the loading and unloading conveying mechanical system, and puts the hexagonal product 46 on the feeding conveyor belt 47 , the feeding conveyor belt 47 transports the hexagonal product 46 to the position below the gripper of the feeding manipulator 16, and the gripper of the feeding manipulator 16 clamps the hexagonal product 46, and the hexagonal product 46 is delivered to the feeding position , the first clamping rotating base 30 on the third turntable 26 holds the bottom of the hexagonal product 46, and the third air cylinder 22 on the first turntable 18 starts to act at the same time, pushing the top block installed on the third air cylinder 22 Move forward to withstand th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com