Printing platform of 3D printer

A 3D printer and printing platform technology, applied in the field of technical 3D printing, can solve problems such as inability to realize rotation and complex support structure, and achieve the effects of reducing printing costs, facilitating replacement, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

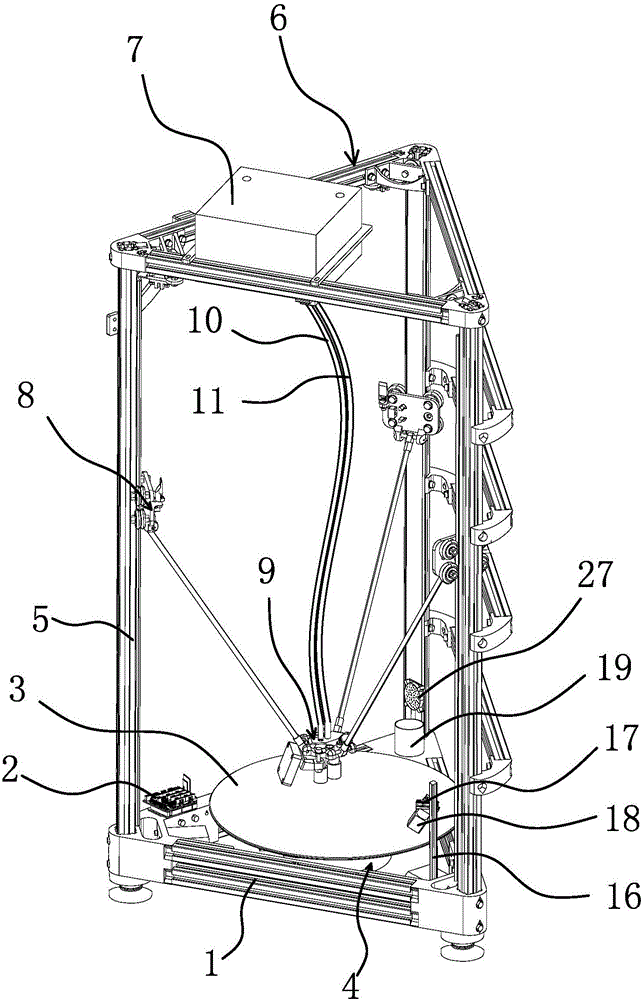

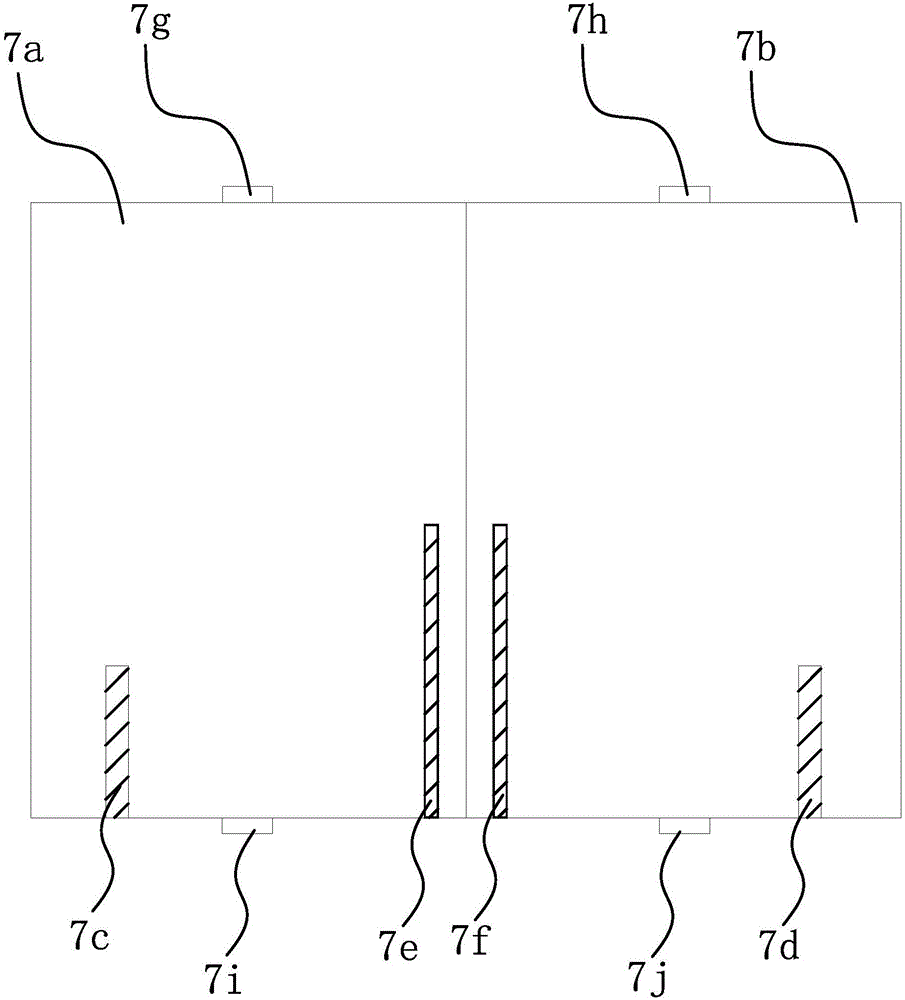

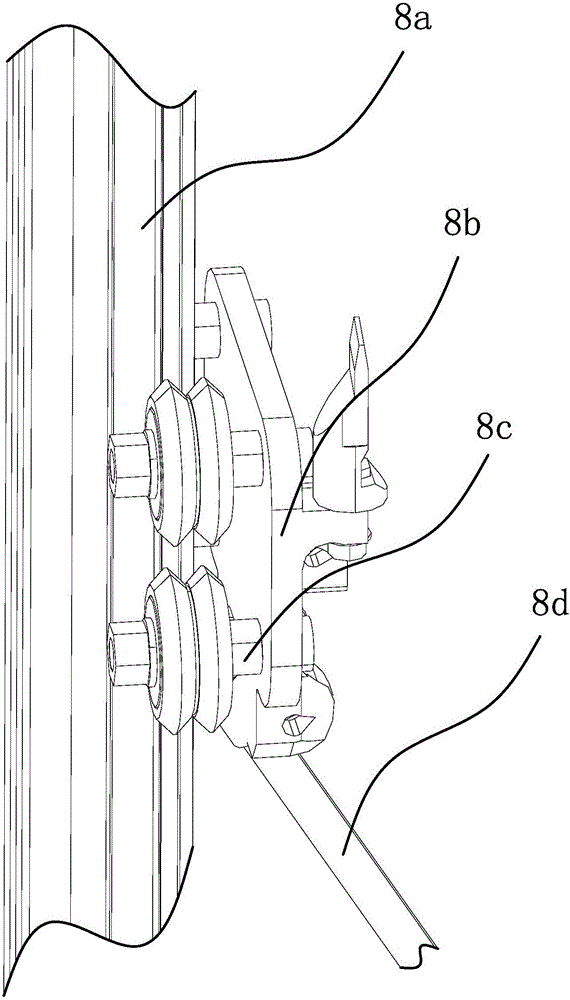

[0031] Such as figure 1 As shown, a 3D printer includes a base 1 and an information processing system 2 arranged on the base 1 for controlling the 3D printer. A printing platform 3 for placing printed objects is arranged above the base 1. Between the base 1 and the printing platform 3 A rotating mechanism 4 capable of driving the printing platform 3 to rotate is provided. Three installation holes are provided on the edge of the base 1. Three uprights 5 are fixed in the three installation holes. The upper ends of the three uprights 5 are fixed with a top frame 6 corresponding to the base 1. A storage box 7 for storing printing materials is provided on the frame 6, a printing nozzle 9 for printing is provided between the three columns 5, and a lifting mechanism 8 for controlling the rising or falling of the printing nozzle 9 is provided between the printing nozzle 9 and the column 5 , the printing nozzle 9 is placed above the printing platform 3, and the base 1 is also provided ...

Embodiment 2

[0042]The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in Embodiment 1, the cleaning device includes a cleaning bucket 19 and a drying assembly, and a lifting structure is provided between the bottom of the cleaning bucket 19 and the base 1 , the lifting structure is a cylinder 20, the cylinder body of the cylinder 20 is fixed on the base 1, the piston rod of the cylinder 20 is vertically upward, the end of the piston rod is fixed with the bottom of the cleaning bucket 19, and the cleaning component is provided in the cleaning bucket 19. Including motor two 21 and motor three 22, the output shaft of motor two 21 and the output shaft of motor three 22 are provided with cleaning ring one 21a and cleaning ring two 22a respectively, and the bottom of the cleaning bucket 19 is provided with a liquid inlet, and the liquid inlet is connected with a The liquid inlet pipe is connected, and a liquid suction pump 24 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com