Robot provided with rotation actuation tail end

A technology for executing terminal and robot, which is applied in the field of robotics and can solve the problems of difficulty in improving the cutting efficiency of PCB boards and large workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

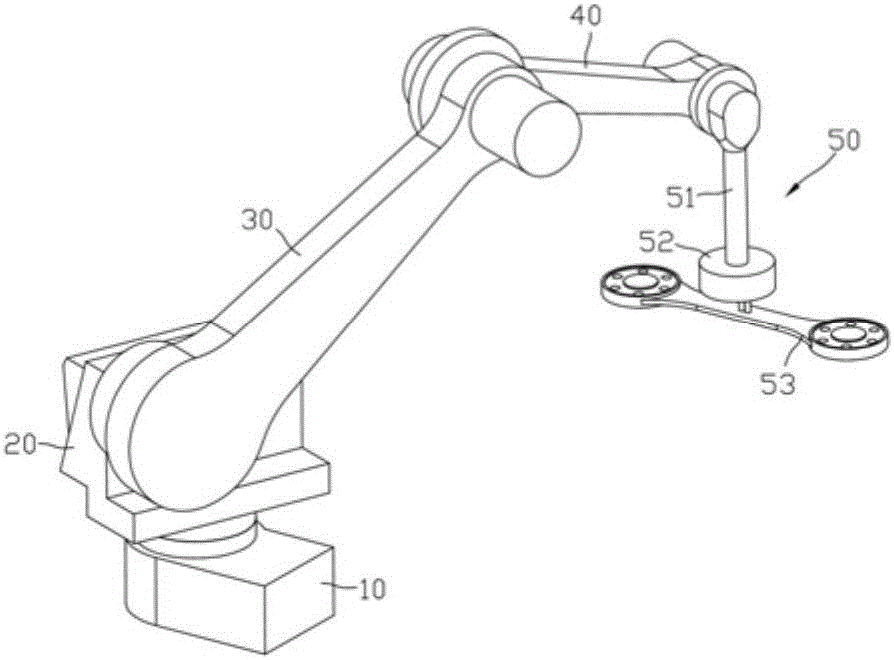

[0043] like figure 1 , a robot provided with a rotating execution end, comprising a base body 10, a waist swivel part 20 pivotally connected to the base body, a big arm 30 pivotally connected to the waist swivel part, and a small arm 40 pivotally connected to the big arm 1. The execution end 50 installed on the forearm, the waist swivel part rotates around the base body, the big arm turns around the waist swivel part, and the small arm turns around the big arm.

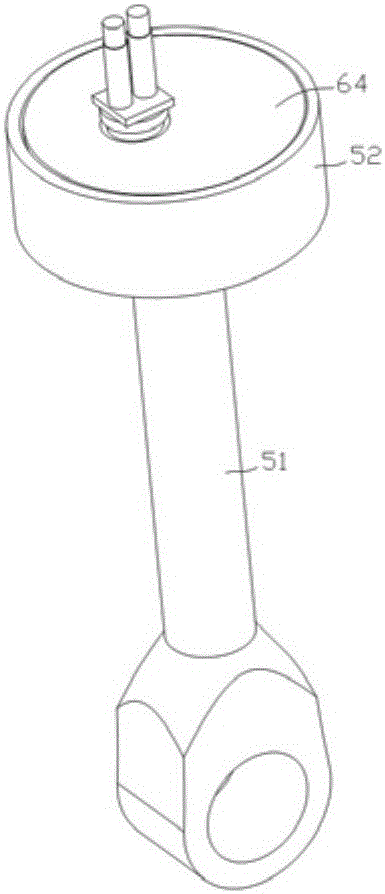

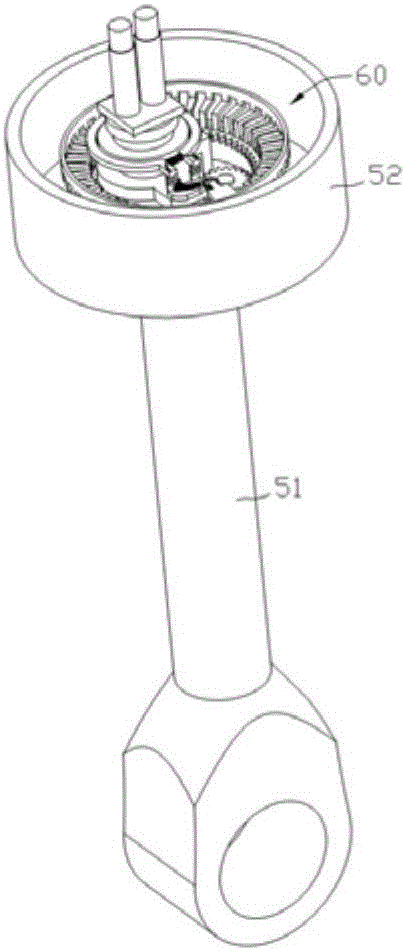

[0044] combine Figure 1 to Figure 3 , the execution end includes a rotating block 53, a pair of suction cup groups fixedly connected with the rotating block, and a drive mechanism 60 for driving the rotating block to rotate; the execution end 50 also includes a connecting arm 51 pivotally connected to the small arm 40, setting The housing 52 on the connecting arm, the cover plate 64 sealed on the housing; the driving mechanism 60 is installed in the housing, the rotating seat 611 in the driving mechanism passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com