Polyhedron shell multi-shaft polisher

A polyhedron and polishing machine technology, which is applied in the direction of polishing machine tools, grinding workpiece supports, metal processing equipment, etc., can solve the problems of large human injury and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

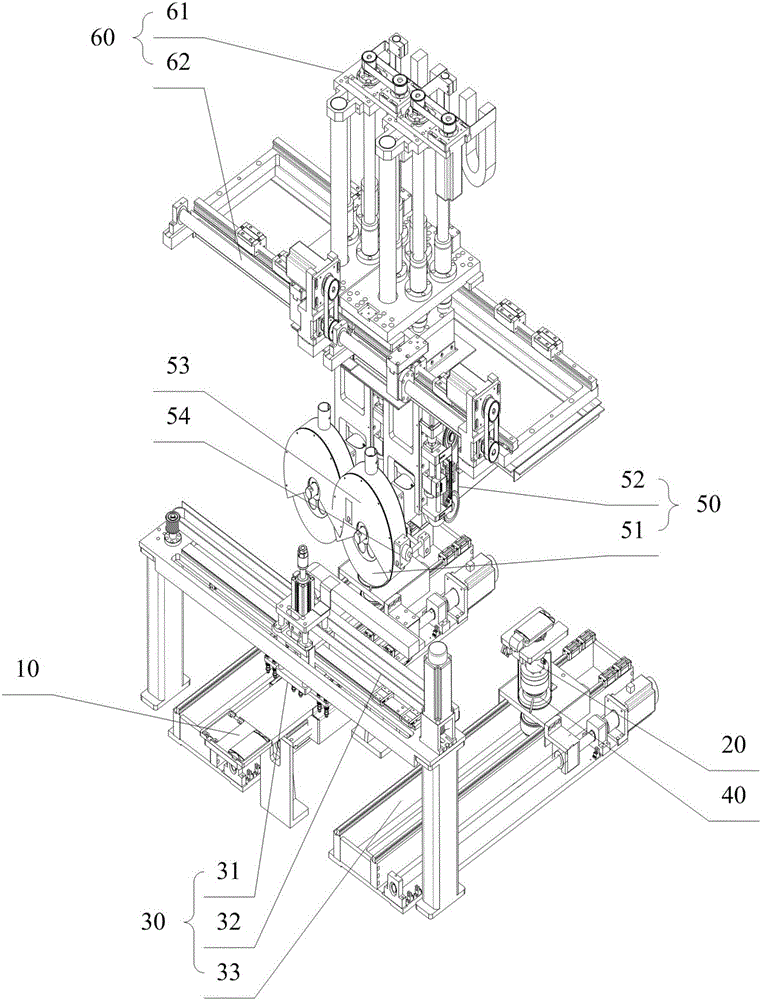

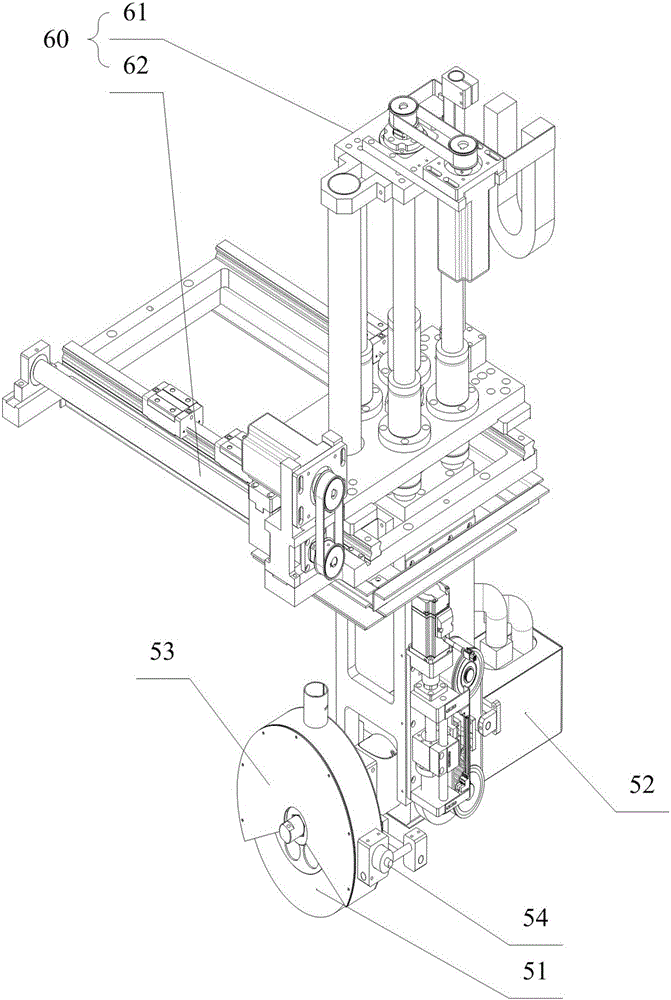

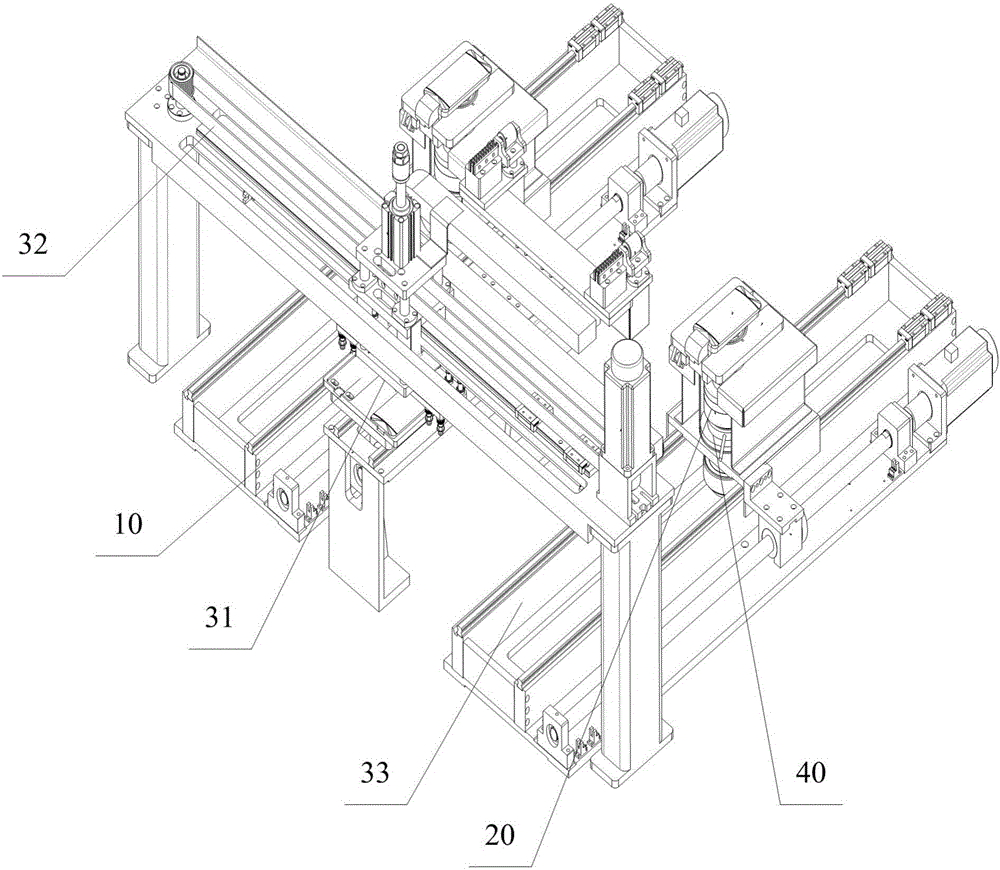

[0024] refer to Figure 1 to Figure 3 , the present invention provides a multi-axis polishing machine for a polyhedron shell. In the embodiment of the present invention, the polyhedron can be a mobile communication terminal, such as a mobile phone, a tablet computer, and the like. The multi-axis polishing machine for polyhedral shells includes at least one polishing device comprising:

[0025] Feeding bracket 10, used to place the fixture for fixing the polyhedron shell;

[0026] A processing position fixing assembly 20, used to fix the clamp;

[0027] The transfer assembly 30 is used to transfer the clamps on the loading bracket 10 to the processing position fixing assembly 20;

[0028] The rotating assembly 40 is located below the processing station fixing assembly 20 and is connected with the processing station ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com