Welded type blade used for CFRP drilling machining

A welding type, blade technology, applied in metal processing equipment, boring machine/drilling machine parts, drill repairing, etc., can solve the problems of hole wall scratches, burrs, fiber tearing, etc., to improve quality, suppress the occurrence of defects, The effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

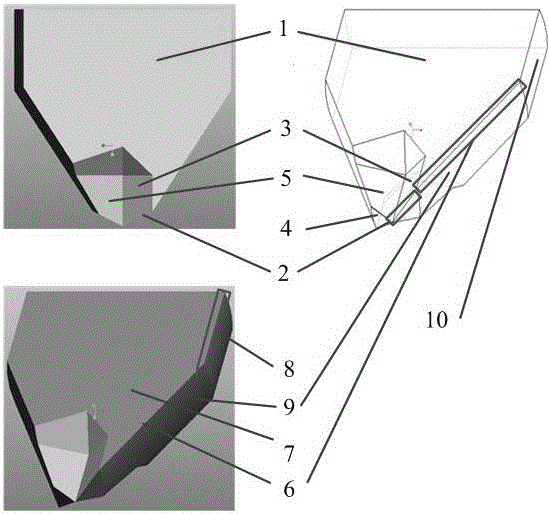

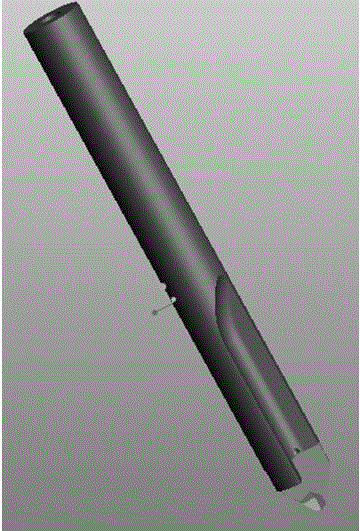

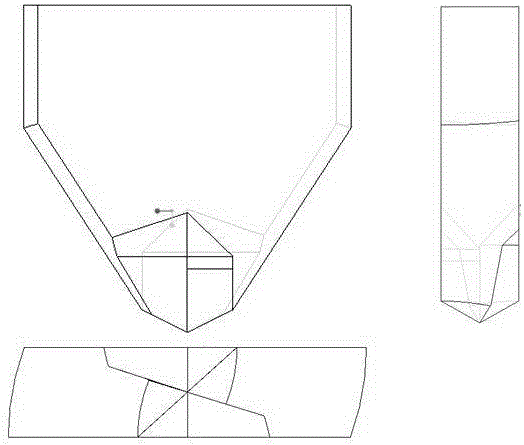

[0015] In this paper, a welded insert for CFRP drilling is designed to reduce defects during CFRP machining. The insert mainly includes: 1-insert body, 2-main cutting edge, 3-main rake face, 4 -First main flank, 5-Second main flank, 6-First auxiliary cutting edge, 7-Auxiliary rake face, 8-Second auxiliary cutting edge, 9-First auxiliary flank, 10 -Second flank.

[0016] The specific effect of each part of the blade designed in this paper, among which the design of 2-main cutting edge, 6-first minor cutting edge, and 8-second minor cutting edge is mainly to reduce the tool’s hole processing. When the axial force and reduce the generation of burrs, the front angle of the 2-main cutting edge is greater than the front angle of the 6-first auxiliary cutting edge. (2-The main cutting edge mainly plays the role of cutting, and its front angle is greater than 118°, 6-The first secondary cutting edge can play the role of cutting when machining th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com