Strip Tail Correction Method for Continuous Rolling Mill

A strip and unit technology, used in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of poor correction effect, instability, lag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

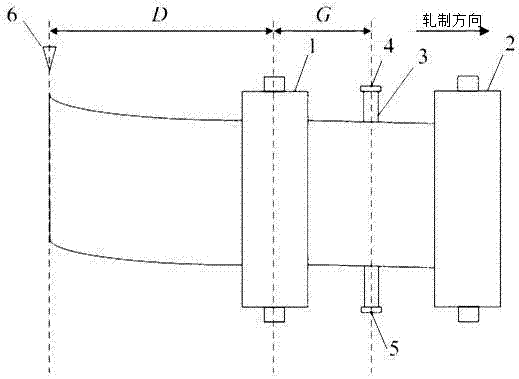

[0041] Such as figure 1 As shown, a metal detector 6 for measuring the tail of the strip is installed before the first frame 1 of the continuous rolling mill, and a first tension measuring roll 3 is installed between the first frame 1 and the second frame 2; A tension measuring roller 3 has a pressure measuring point 4 on the transmission side and a pressure measuring point 5 on the operating side; D is the horizontal distance from the metal detector 6 to the central axis of the roll in the first stand 1, in millimeters; G is the roll gap of each stand The horizontal distance from the pressure measuring point of the tension measuring roller behind it, in millimeters.

[0042] The present invention considers that when the rolling piece of the intermediate billet is rolled to the end of the continuous rolling mill, the metal detector arranged at the entr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com