Fruit enzyme and preparation method thereof

A fruit enzyme and fructooligosaccharide technology, applied in the field of enzymes, can solve problems such as the unsatisfactory health care effect of enzymes, and achieve the effects of enhancing lipid-lowering and blood pressure-lowering effects, dredging blood vessels, and avoiding excessive accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

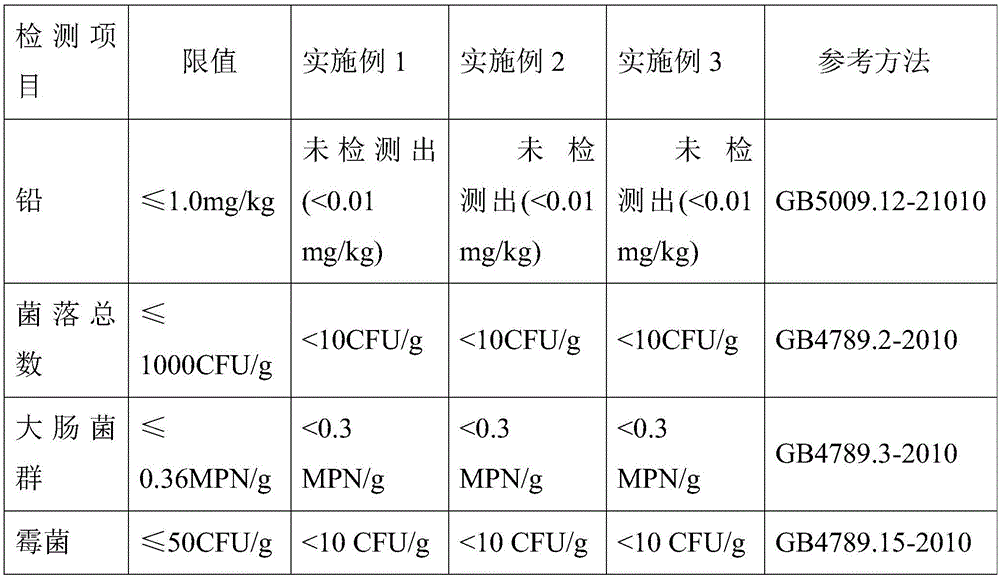

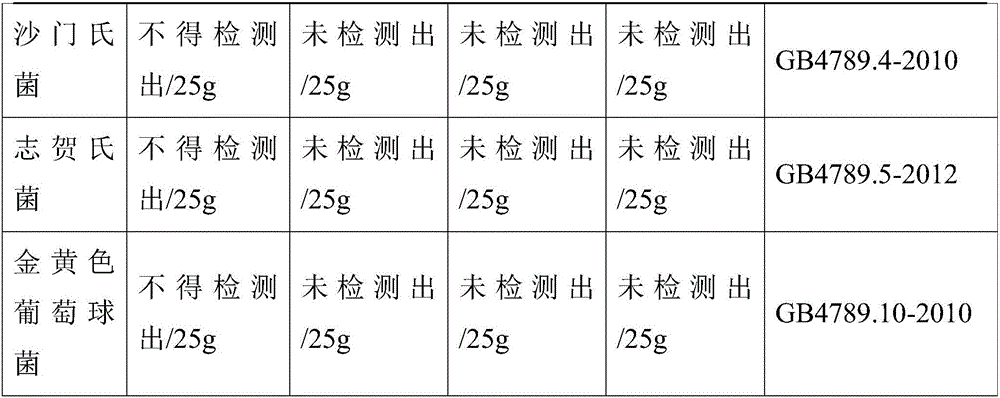

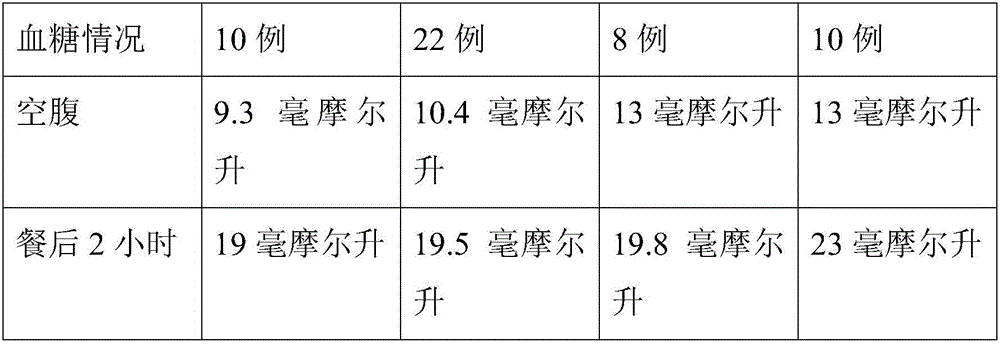

Examples

Embodiment 1

[0021] Fruit enzyme, its preparation method is:

[0022] 1) In parts by weight, weigh 50 parts of greengage, 10 parts of black plum, 10 parts of hawthorn, 8 parts of licorice, 10 parts of fructooligosaccharide, and 10 parts of isomaltose, and mix and stir them evenly;

[0023] 2) In parts by weight, weigh 28 parts of yeast extract, including 10 parts of proteolytic enzyme, 8 parts of lipolytic enzyme and 10 parts of amylolytic enzyme, add to the mixture obtained in step 1), stir evenly, and perform enzymolysis , the enzymolysis temperature is 25°C, the enzymolysis time is 40 minutes, and then filtered to obtain the fruit enzyme.

Embodiment 2

[0025] Fruit enzyme, its preparation method is:

[0026] 1) In parts by weight, weigh 45 parts of greengage, 12 parts of black plum, 12 parts of hawthorn, 6 parts of licorice, 8 parts of fructooligosaccharide, and 12 parts of isomaltose, and mix and stir them evenly;

[0027] 2) In parts by weight, weigh 26 parts of yeast extract, wherein the mass ratio of proteolytic enzyme, lipolytic enzyme and amylolytic enzyme is 2:2:1, add it to the mixture obtained in step 1), stir evenly, Carry out enzymolysis, enzymolysis temperature is 28 ℃, enzymolysis time is 30 minutes, then filter to obtain fruit enzyme.

Embodiment 3

[0029] 1) In parts by weight, weigh 55 parts of greengage, 8 parts of black plum, 8 parts of hawthorn, 10 parts of licorice, 12 parts of fructooligosaccharide, and 8 parts of isomaltose, and mix and stir them evenly;

[0030] 2) In parts by weight, weigh 30 parts of yeast extract, wherein the mass ratio of proteolytic enzyme, lipolytic enzyme and amylolytic enzyme is 2:2:1, add it to the mixture obtained in step 1), stir evenly, Carry out enzymolysis, enzymolysis temperature is 30 ℃, enzymolysis time is 20 minutes, then filter to obtain fruit enzyme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com