A deep loosening fertilization ditch press bed seeder

A seeding machine and subsoiling technology, applied in agricultural machinery and tools, devices for catching or killing insects, agriculture, etc., can solve the problems of difficult control of sowing depth, invisible subsoiling effect, and freezing of wheat seedlings due to moisture loss, etc. Achieve the effect of improving water storage and moisture conservation capacity, obvious effect of increasing production, and improving emergence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

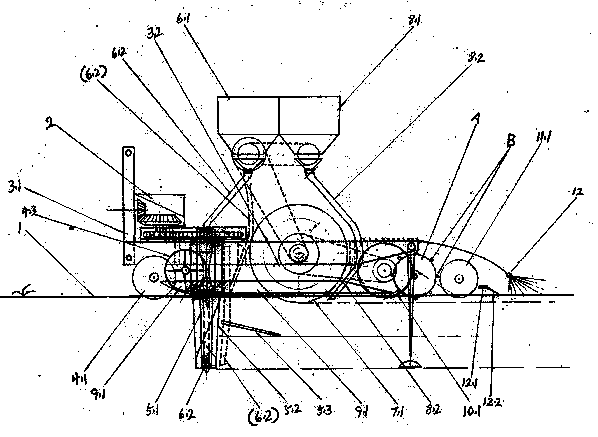

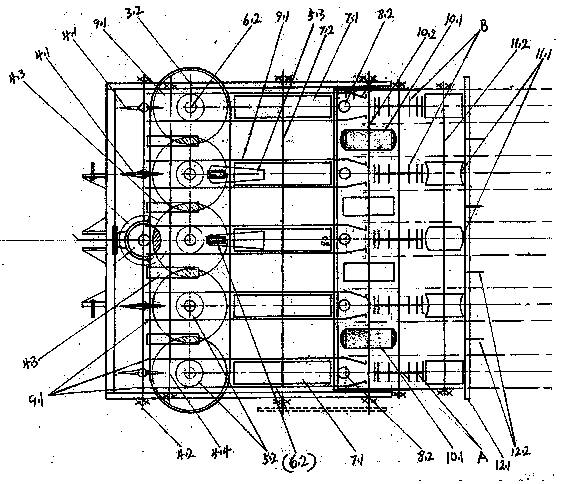

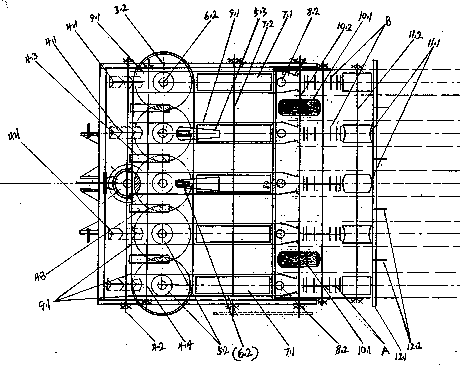

[0045] Such as figure 1 , 2 , 3 shows a specific embodiment of the present invention.

[0046] This embodiment is an interval subsoiling fertilization press ditch bed-making planter, which includes a gearbox 2, a traction frame, an anti-winding mechanism, an interval subsoiling mechanism, a fertilizer applicator, a ditch-pressing bed-making mechanism, a seeder, a gathering mechanism, Vertical positioning mechanism, crushed soil covering wheel A, suppression mechanism, pesticide sprayer 12 and related transmission devices, etc.

[0047] Wherein, one end of the gearbox 2 is connected to the power source, and the direction of the torque is changed to provide power and a suitable transmission ratio for the subsequent working mechanism.

[0048] The traction frame includes traction frame 3.1 and frame 3.2, the traction frame is connected and fixed with the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com