Organic light-emitting diode display substrate, manufacturing method therefore, and display device thereof

A technology for light-emitting diodes and display substrates, which is used in semiconductor/solid-state device manufacturing, electrical components, and electrical solid-state devices, etc., and can solve problems such as large climbing distances for organic thin films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manner of the present invention will be further described in detail below with reference to the drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0042] Please refer to Figure 4 , Figure 4 It is a cross-sectional view of an organic light emitting diode display substrate according to Embodiment 1 of the present invention. The organic light emitting diode display substrate according to this embodiment of the present invention includes: a base substrate 401, an organic light emitting diode device 402 disposed on the base substrate 401, and a thin film package A layer 403 and a hydrophobic barrier 404, the thin film encapsulation layer 403 is used to encapsulate the organic light emitting diode device 402, and includes an inorganic thin film layer 4031 and an organic thin film layer 4032 arranged alternately. The hydrophobic barrie...

PUM

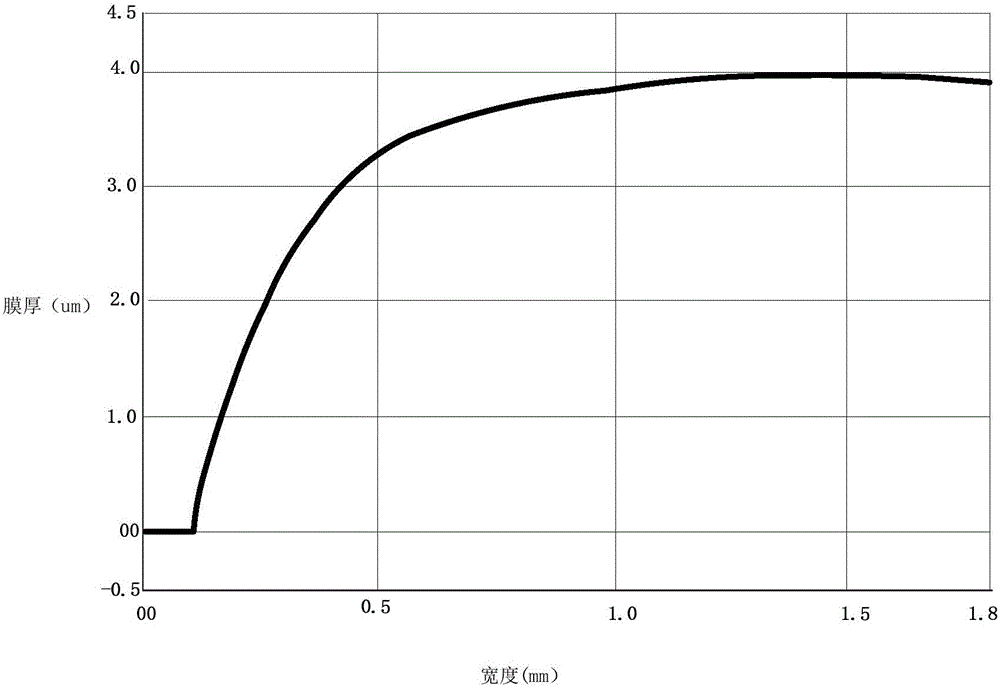

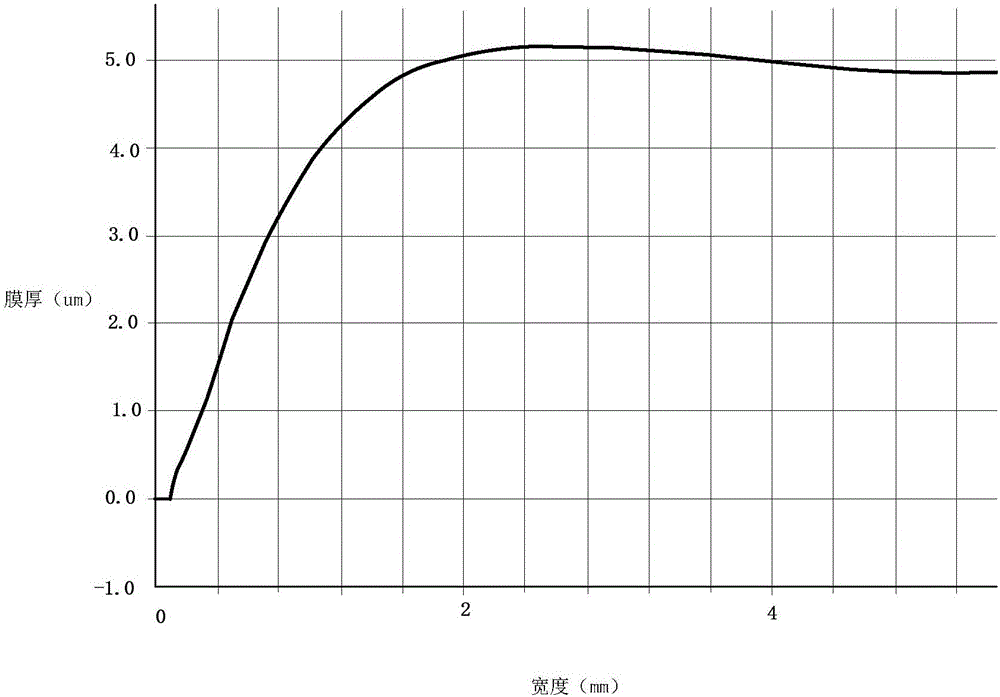

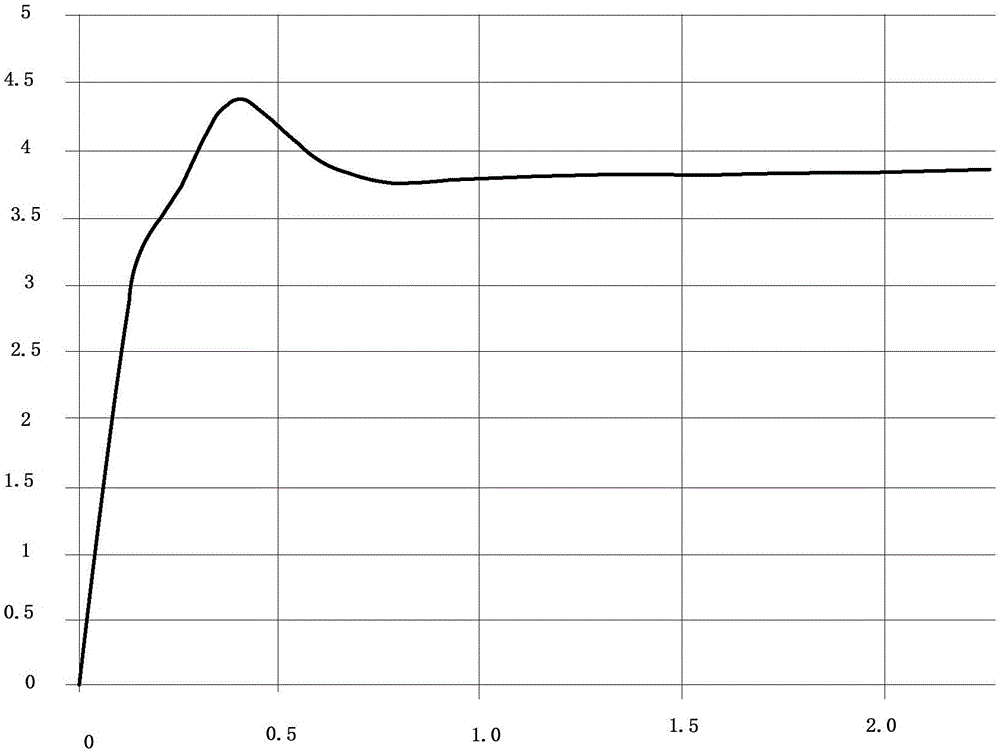

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com