Bending machine numerical control system device with embedded robot for control and method thereof

A numerical control system, robot technology, applied in general control system, control/regulation system, digital control and other directions, can solve the problems of low efficiency, affect processing efficiency, unusable, etc., achieve simple and fast operation process, save repeated positioning time, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

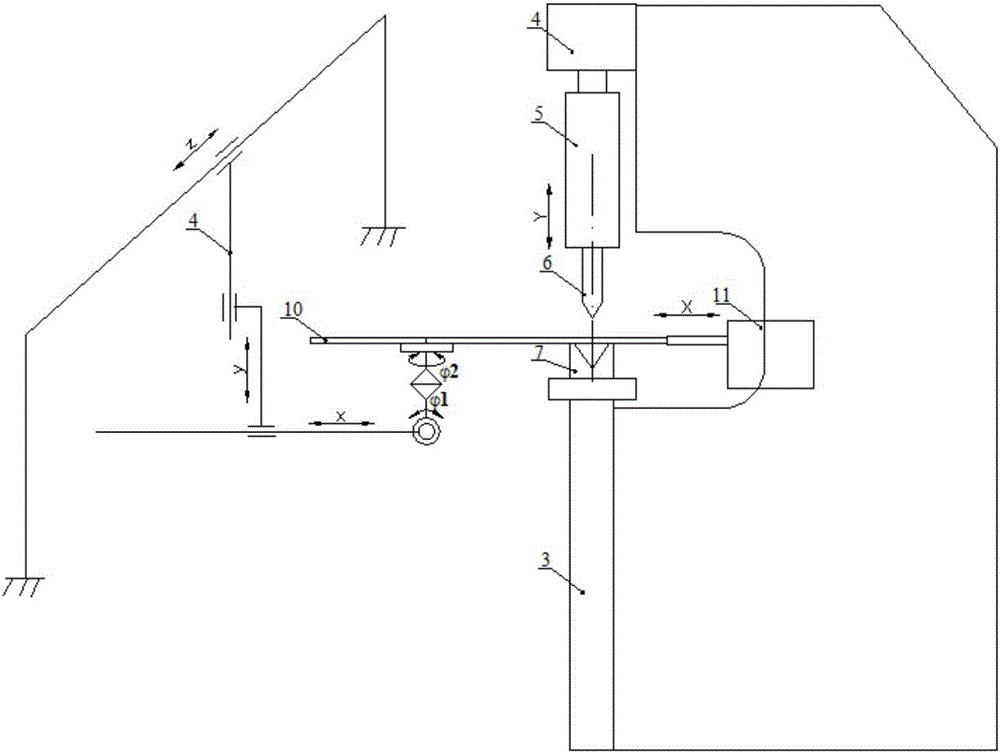

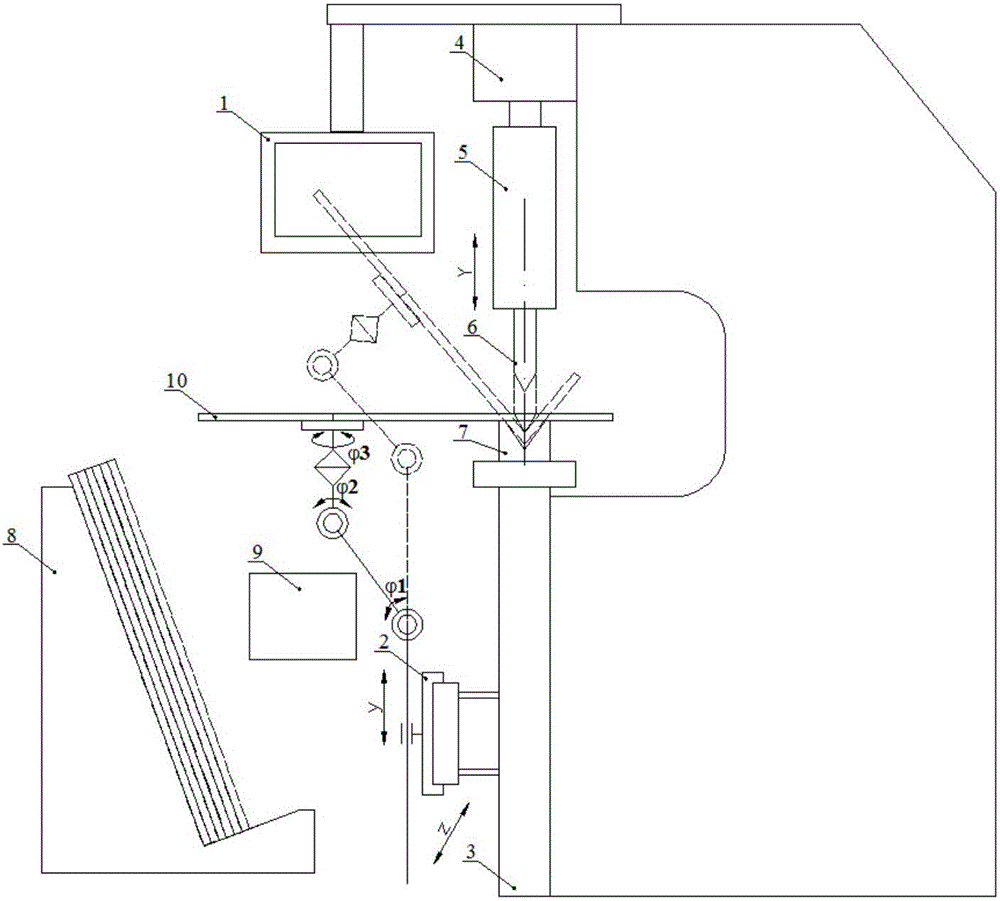

[0028] Corresponding reference characters indicate corresponding parts throughout the views of the drawings.

[0029] A bending machine numerical control system device with embedded robot control, the bending machine numerical control system device includes a numerical control system 1, a robot 2, a frame 3, a slider control mechanism 4, a slider 5, an upper die 6, a lower die 7, The loading frame 8, the discharge station 9 and the workpiece 10, the numerical control system 1 is set on the frame 3, the robot 2 is set on the frame 3, the slider control mechanism 4 pushes the slider 5 to run up and down, and the upper mold 6 is installed on the slider On the block 5, a lower mold 7 is set under the upper mold 6, the lower mold 7 is arranged on the frame 3, the feeding rack 8 is installed on the left side of the frame 3, the discharge station 9 is installed on the right side of the frame 3, and the workpiece 10 is installed by the robot. 2. The gripper grabs or releases. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com