Pull-out performance test fixture and full-fit display device pull-out performance test method

A technology for testing jigs and display devices, which is applied in measuring devices, mechanical devices, nonlinear optics, etc., can solve the problems of ineffectiveness of pulling force and pulling distance, complicated testing process, etc., and improve the pulling performance. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

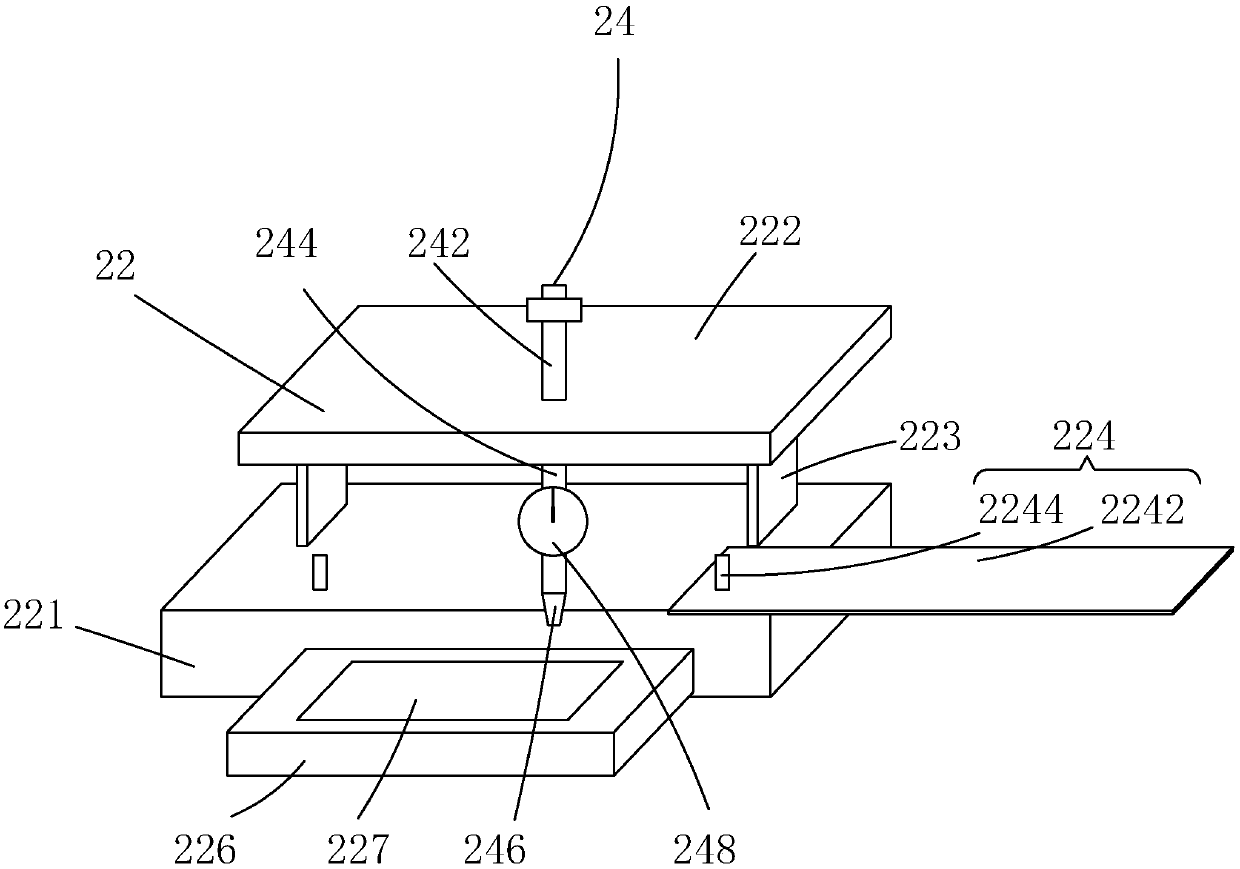

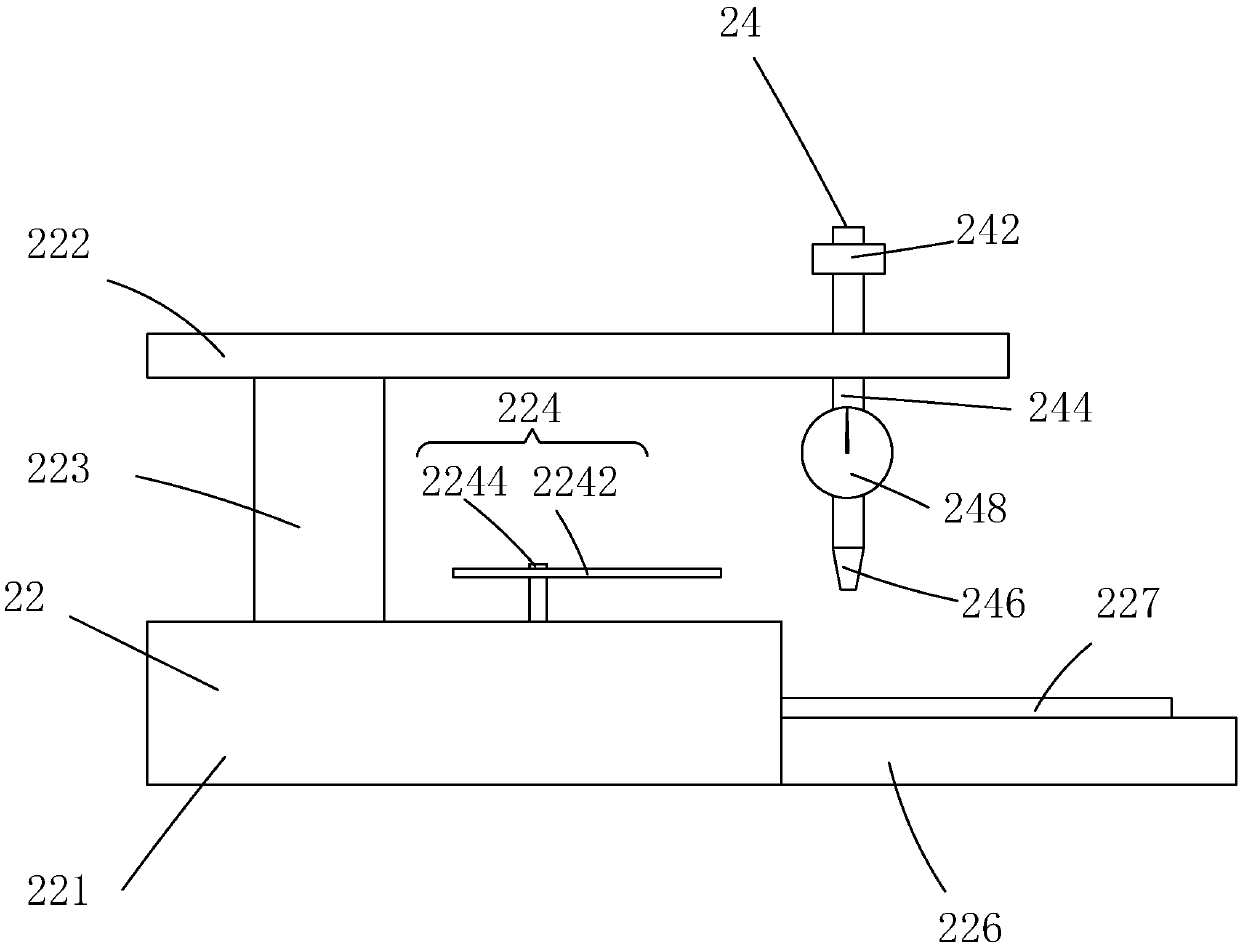

[0041] see Figure 1 to Figure 2 , the present invention provides a pullout performance test fixture, comprising: a fixture frame 22, and a test portion 24 arranged on the fixture frame 22;

[0042] The jig frame 22 includes: a base 221, a top plate 222 opposite to the base 221, a support portion 223 connecting the base 221 and the top plate 222, and a fixing portion 224 arranged on the top surface of the base 221;

[0043] The test part 24 is installed on the top board 222, and the test part includes 24: a test rod 244, a distance measuring unit 242 mounted on one end of the test rod 244 and positioned on the top board 222, and a distance measuring unit 242 positioned at the other end of the test rod 244. An indenter 246 and a pressure measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com