Device and method for mounting recyclable surrounding rock fracture monitoring acoustic emission sensor

A technology for acoustic emission sensors and installation devices, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of sensor failure and low signal recognition, and achieve the effects of improving installation efficiency, optimizing application effects, and isolating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0027] The invention provides a recyclable surrounding rock rupture monitoring acoustic emission sensor installation device and method.

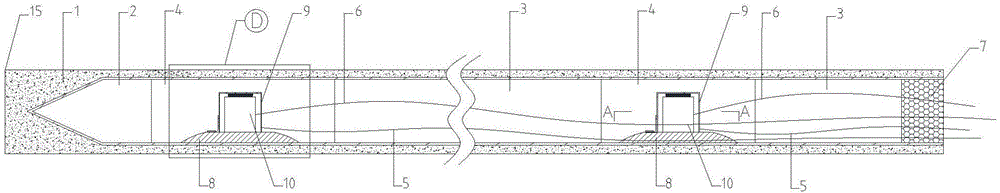

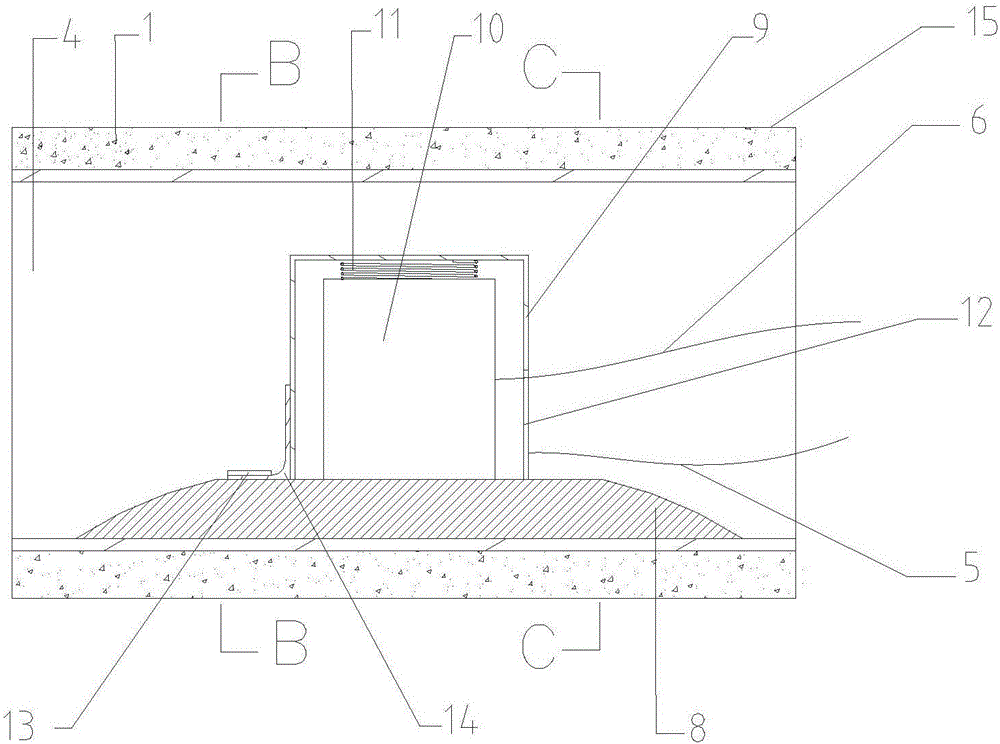

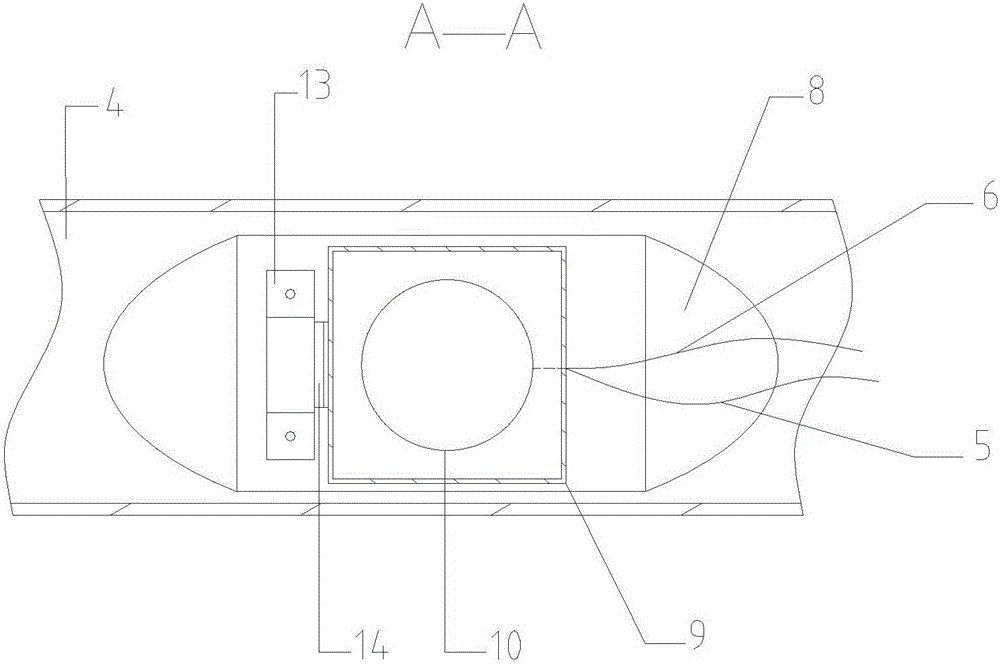

[0028] Such as figure 1 Shown is a schematic diagram of the overall structure of the embodiment of the present invention, figure 2 for figure 1 The enlarged schematic diagram of the middle part, image 3 , Figure 4 , Figure 5 Sectional drawing, combined with figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , the protection tube is composed of the pipe head 2, the installation pipe 4 and the connecting pipe 3. After the protection tube is inserted into the borehole 15, resin drug rolls, cement slurry or other bonding materials can be used to form a bonded coupling body 1 so that the protection tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com