Device and method for detecting heated coke formation propensity of solid heavy raw material

A technology of heavy raw materials and heating devices, applied in measuring devices, material weighing, analyzing materials, etc., to achieve real-time online continuous measurement, short test time, and increased reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

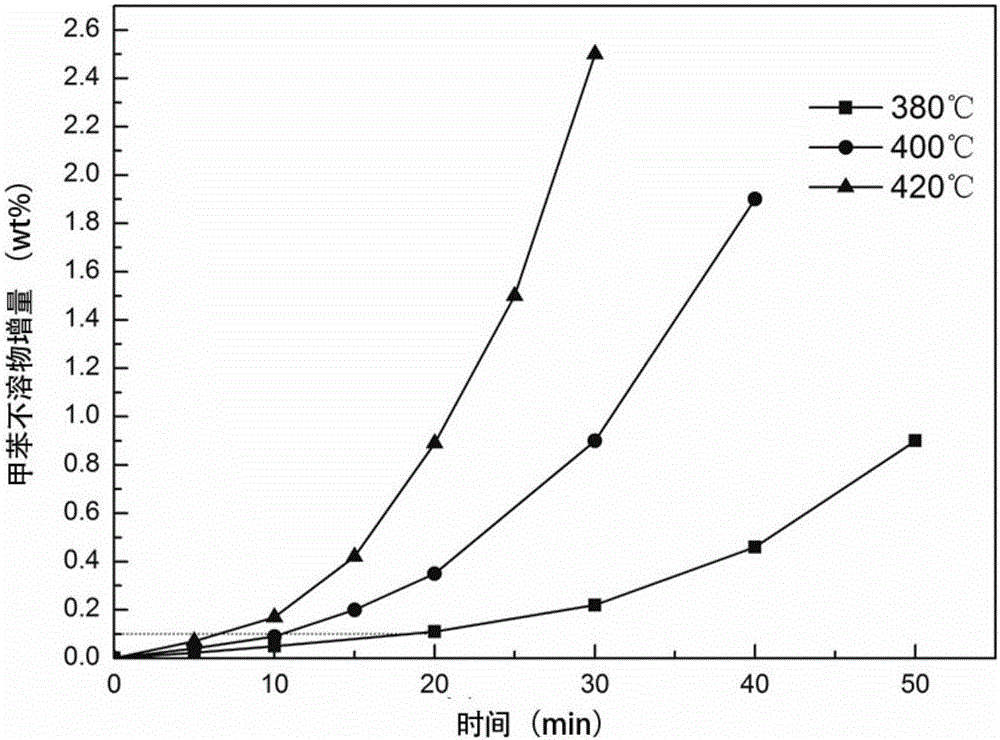

[0052] like figure 2 As shown, under the conditions of 0.2MPa and temperatures of 380°C, 400°C, and 420°C, the coke trend curves of coal liquefaction containing solid heavy raw materials are measured, see the attached figure 2 , when the measured reaction temperature is 380°C, the coke induction period is 19min; when the measured reaction temperature is 400°C, the coke induction period is 11min; when the measured reaction temperature is 420°C, the coke induction period is 7min.

Embodiment 2

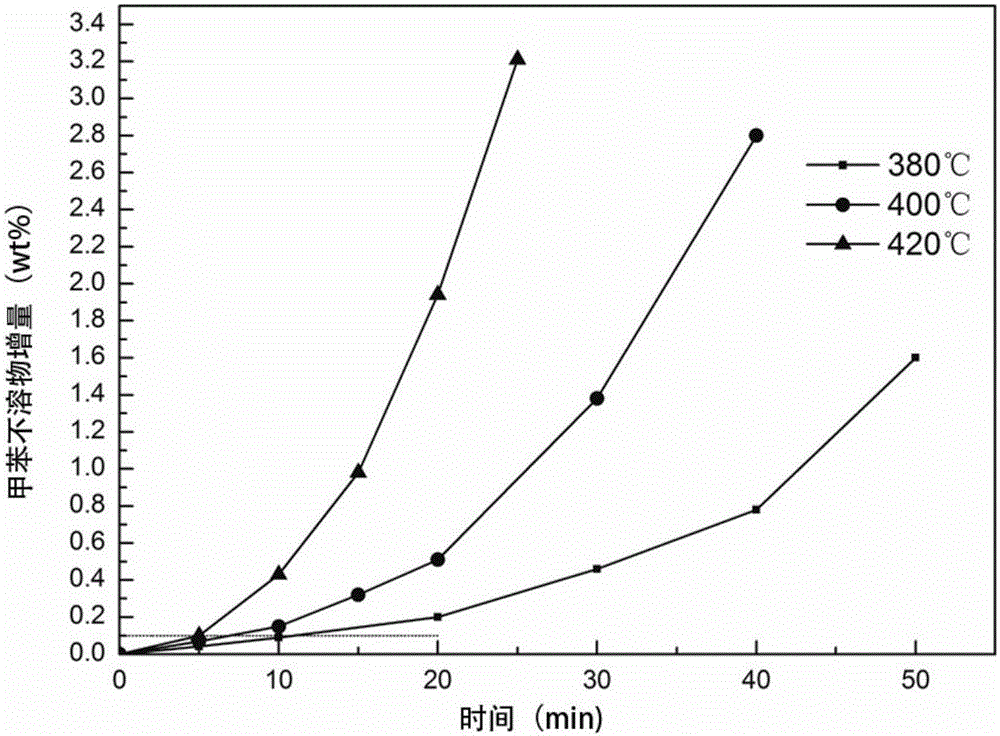

[0054] like image 3 As shown, under the conditions of 0.2MPa and temperatures of 380°C, 400°C, and 420°C respectively, the coke trend curves of coal liquefaction containing solid heavy raw materials after distillation are measured, see the attached image 3 , when the measured reaction temperature is 380°C, the coke induction period is 10 minutes; when the measured reaction temperature is 400°C, the coke induction period is 6 minutes; when the measured reaction temperature is 420°C, the coke induction period is 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com