System for evaluating reliability of bogie rolling bearing based on offline state vibration characteristics

A feature evaluation and bogie technology, applied in the direction of mechanical bearing testing, mechanical component testing, machine/structural component testing, etc., can solve the problems of increased vibration signal collection, large amount of operation and maintenance, high cost, etc., to avoid interference, Accurate data, avoiding the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

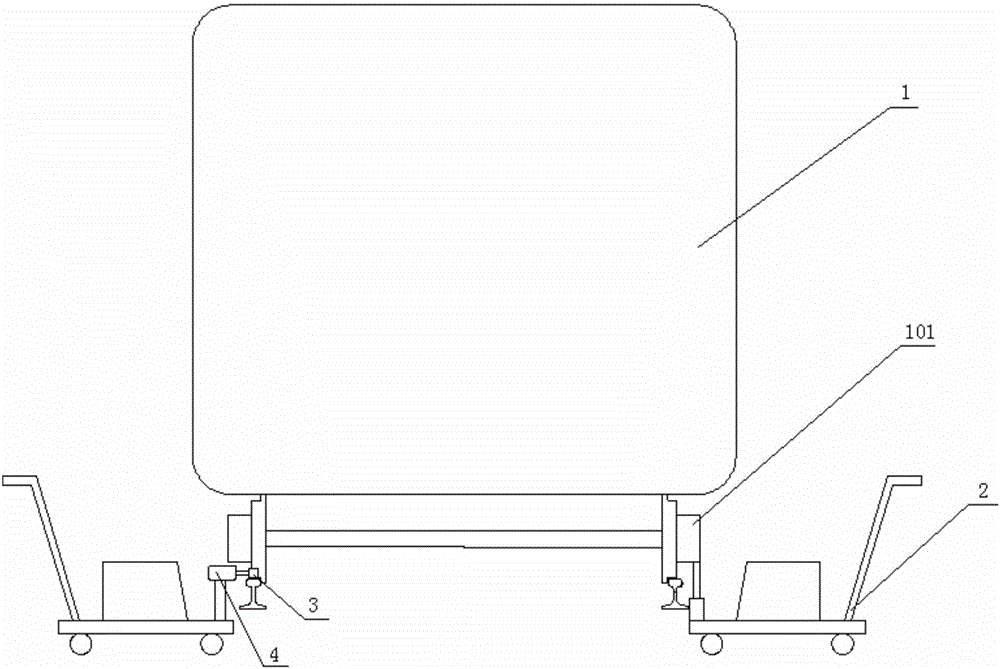

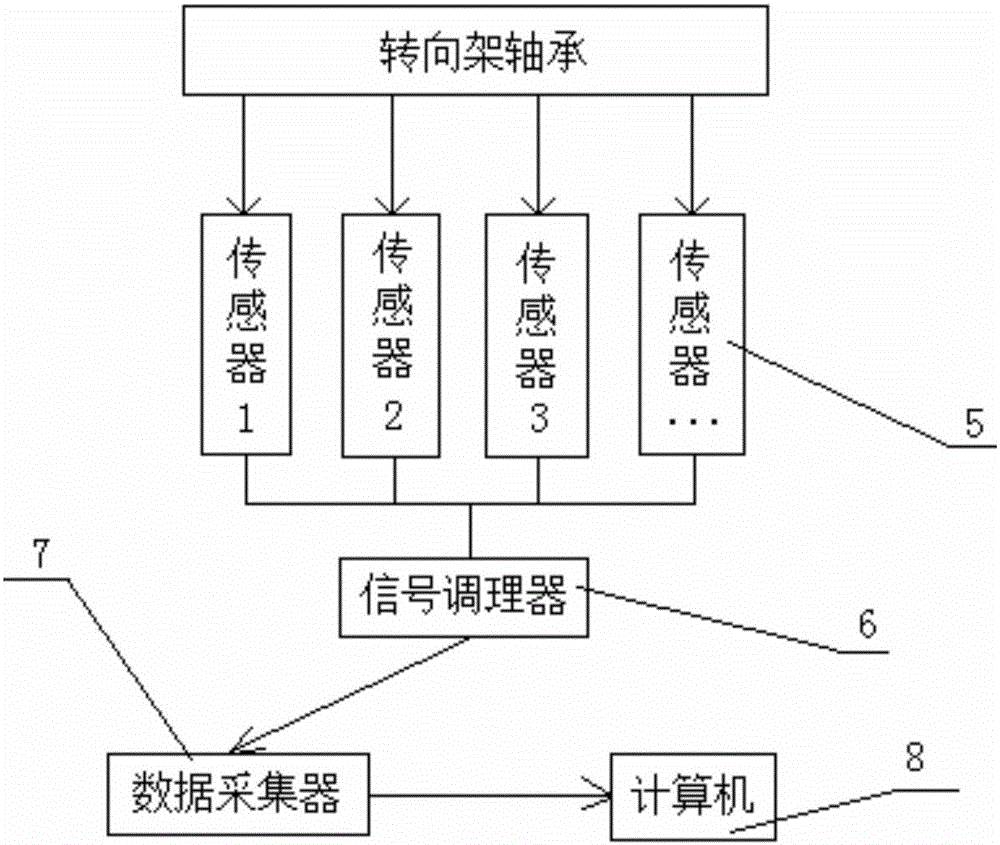

[0019] Such as figure 1 and figure 2 As shown, the present invention provides a system for evaluating the reliability of bogie rolling bearings based on off-line vibration characteristics, including a jacking device 2, a friction wheel 3, a motor 4, several sensors 5, a signal conditioner 6, a data collector 7 and computer8.

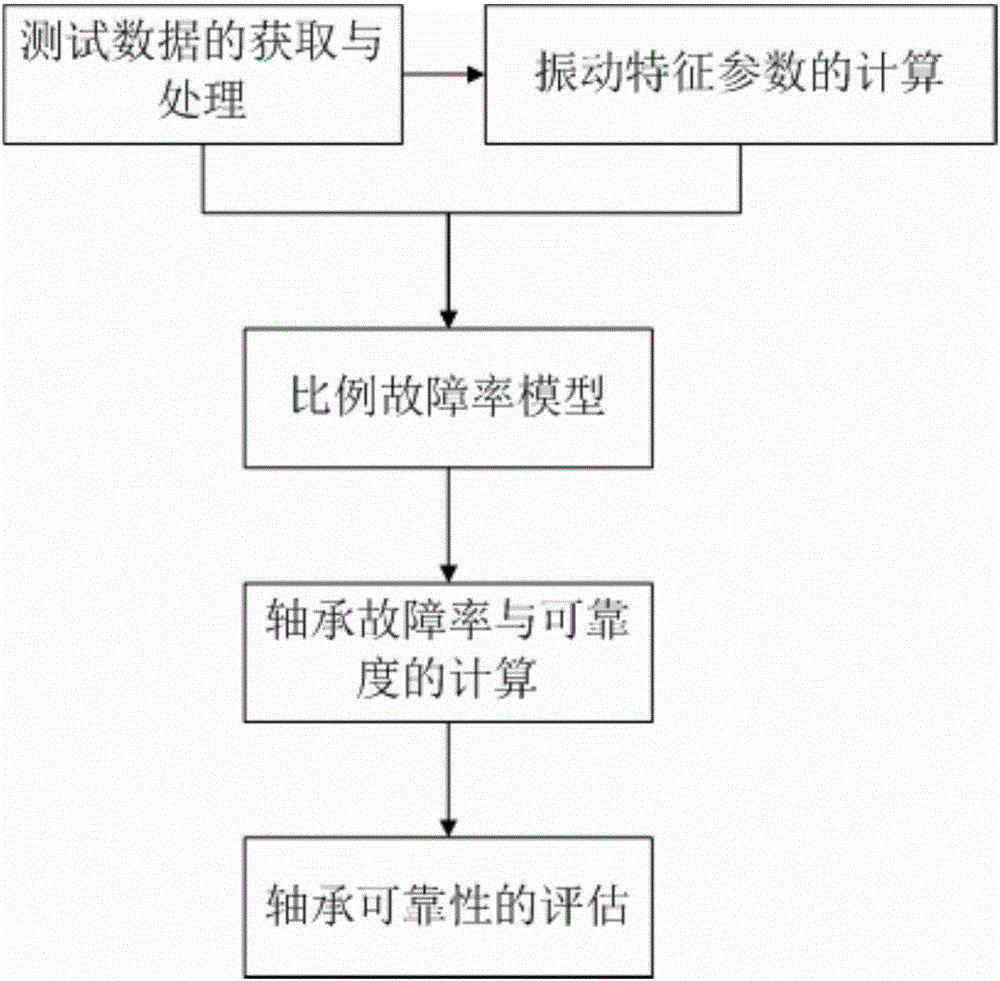

[0020] Such as image 3 Shown, the working steps of the present invention are as follows:

[0021] When the vehicle under test 1 is in the off-line state, the wheel pair 101 of the vehicle under test 1 is lifted by the jacking device 2, so that the wheel rail 101 is in the wheel-rail separation state. The height of the wheel set 101 of the test vehicle 1 is more than 5mm, but the present invention is not limited to this. The friction wheel 3 is drivingly connected to the wheel pair 101 of the vehicle und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com